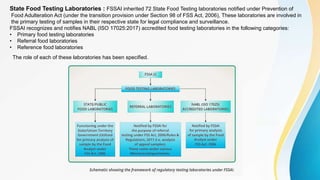

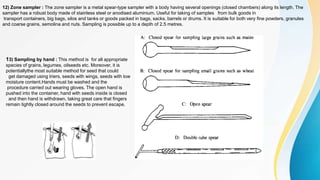

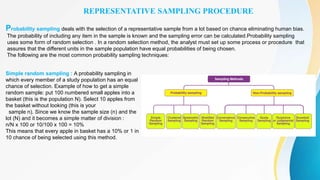

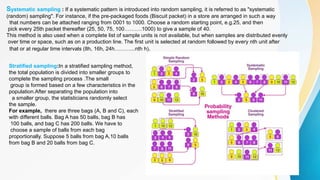

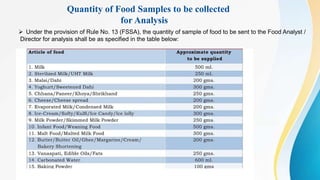

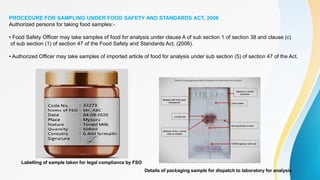

This document discusses sampling and food testing. It begins by defining sampling as selecting a portion of a food lot to represent the whole lot. Samples are collected for various purposes like surveillance, data collection, or determining if a product meets standards. The objectives of food testing are then outlined as protecting public health, detecting fraud, ensuring compliance with standards, and more. Legal provisions related to sampling and analysis from the Food Safety and Standards Act are described. Key definitions used in sampling like lot, sample, and composite sample are explained. Acceptance sampling plans including attribute and variables plans are covered. Health and safety precautions for sampling and general principles for legal sampling are provided. Finally, various tools used for sampling different types of foods are identified.

![FORM III

[Refer rule 3.3.2.(1)]

(to keep any article of food in safe custody of the vender)

To

(Name and address of the vendor)

………………………………….

………………………………….

………………………………….

Whereas *…………………………….intended for food which is in your possession appears to me to be

adulterated/misbranded:

Now therefore under clause (c) of sub-section (1) of section 38 of the Food Safety and Standards Act, 2006

(34

of 2006), I hereby direct you to keep in your safe custody the said sealed stock subject to such orders as may

be

issued subsequently in relation thereto.

Food Safety Officer

Area…………

Place:

Date:](https://image.slidesharecdn.com/presentation1-230119140740-53fd463b/85/Presentation1-pptx-32-320.jpg)