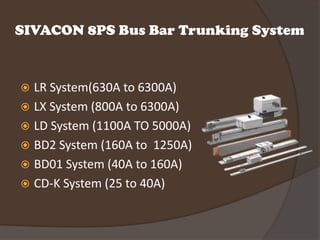

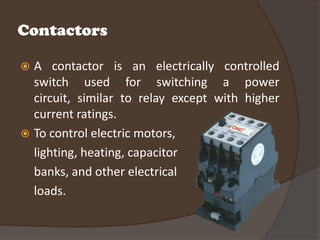

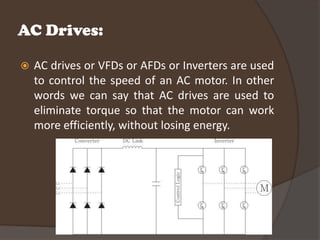

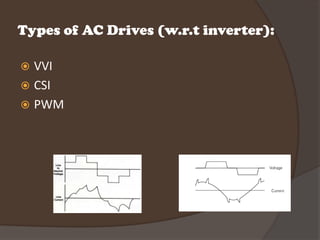

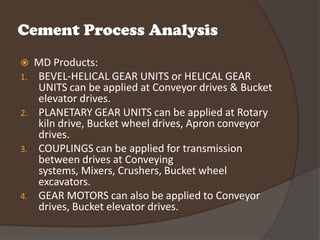

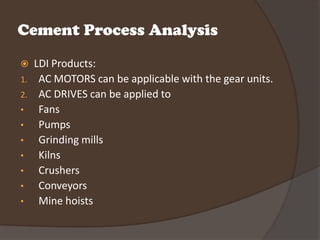

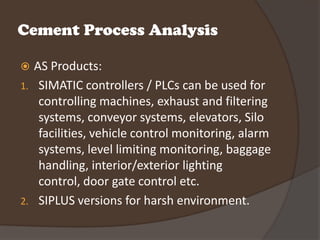

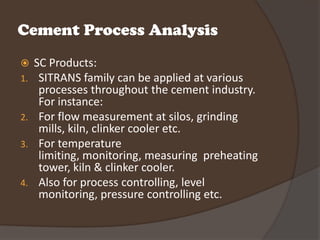

Siemens provides various products for cement manufacturing processes including [1] busbar trunking systems, contactors, and circuit breakers for power distribution; [2] gear units, gear motors, and couplings for mechanical drives; [3] AC motors and drives to power fans, pumps, mills, and other machines; [4] PLCs and sensors for automation and process control throughout cement production.