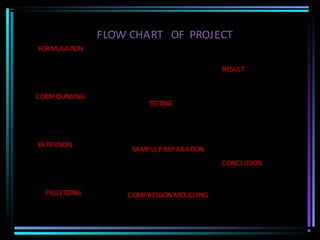

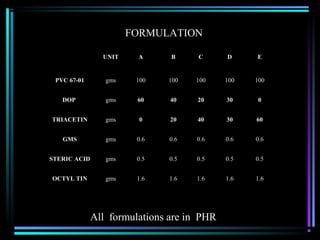

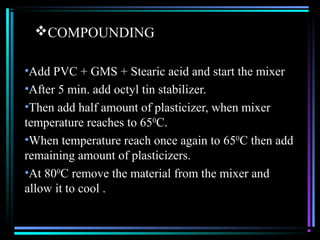

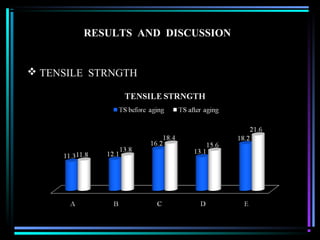

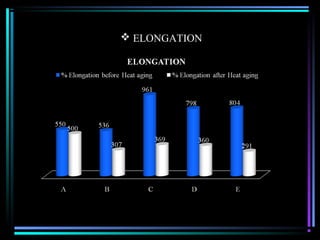

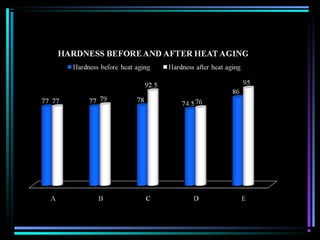

The document outlines a training presentation on the Product Application and Research Center (PARC) of Reliance Industries Limited, focusing on the partial replacement of dioctyl phthalate (DOP) with triacetin in plastic formulations. It discusses the health concerns related to DOP and presents experimental results showing that while triacetin enhances tensile strength and hardness, it is not suitable for complete replacement of DOP, but can be used partially. The conclusion emphasizes that triacetin can be beneficial in applications requiring a shorter shelf life.