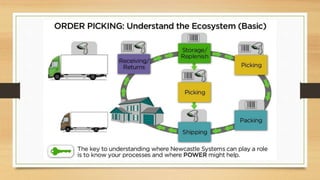

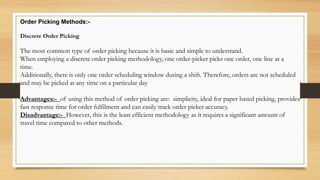

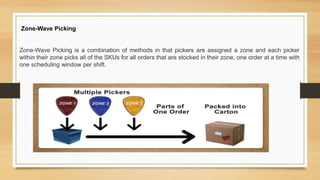

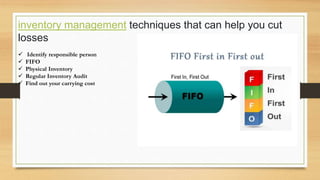

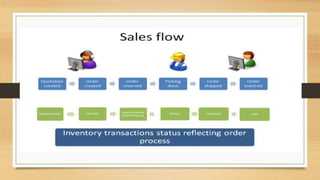

Order picking involves selecting individual items from a warehouse to fulfill client orders. There are several common order picking methods, each with advantages and disadvantages. Discrete order picking involves one picker selecting one full order at a time, providing fast fulfillment but lower efficiency due to travel time. Batch picking allows a picker to select multiple orders' worth of the same item in one trip, improving productivity but risking mistakes. Wave and zone-wave picking combine aspects of discrete and batch picking. Proper inventory management techniques like regular audits and identifying responsible personnel can help address issues that cause delays or losses.