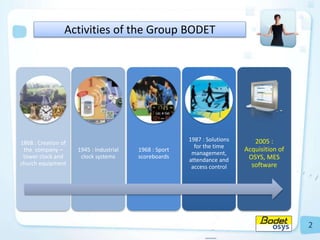

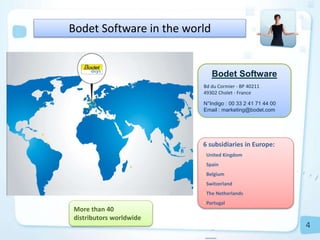

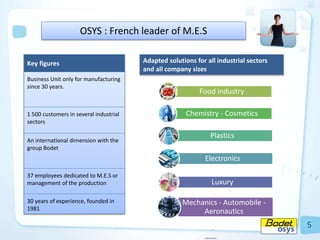

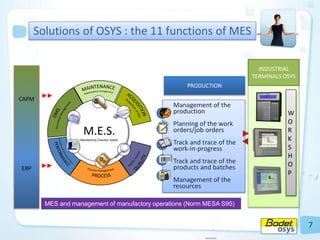

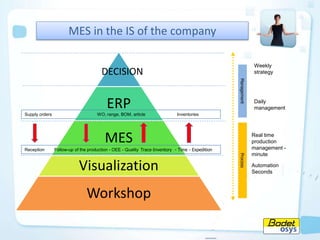

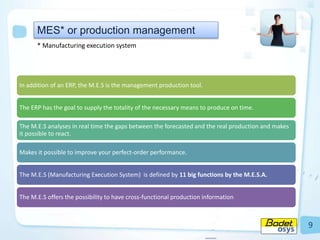

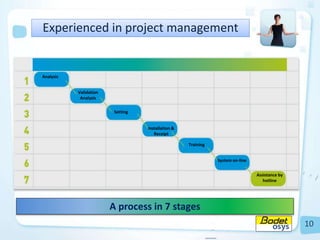

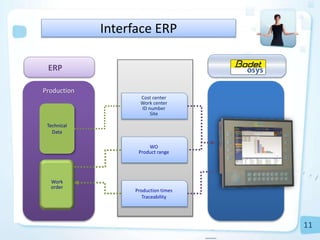

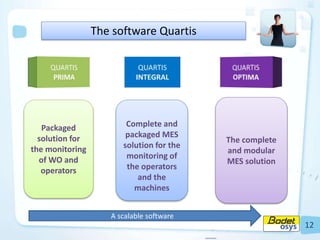

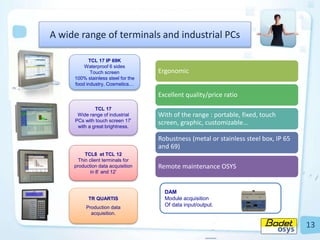

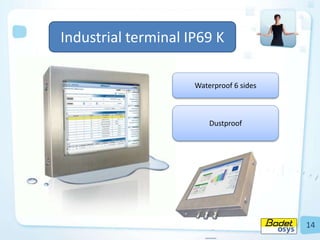

The document summarizes information about the company Bodet and its software division Bodet Software. It details the company's history starting in 1868 with tower clocks and expanding into industrial clock systems, sport scoreboards, and software solutions. Bodet Software's MES software called OSYS is highlighted as the French leader in MES and has over 1,500 customers across various industrial sectors. Key features of the OSYS software suite and the benefits of its modular MES solutions are summarized.