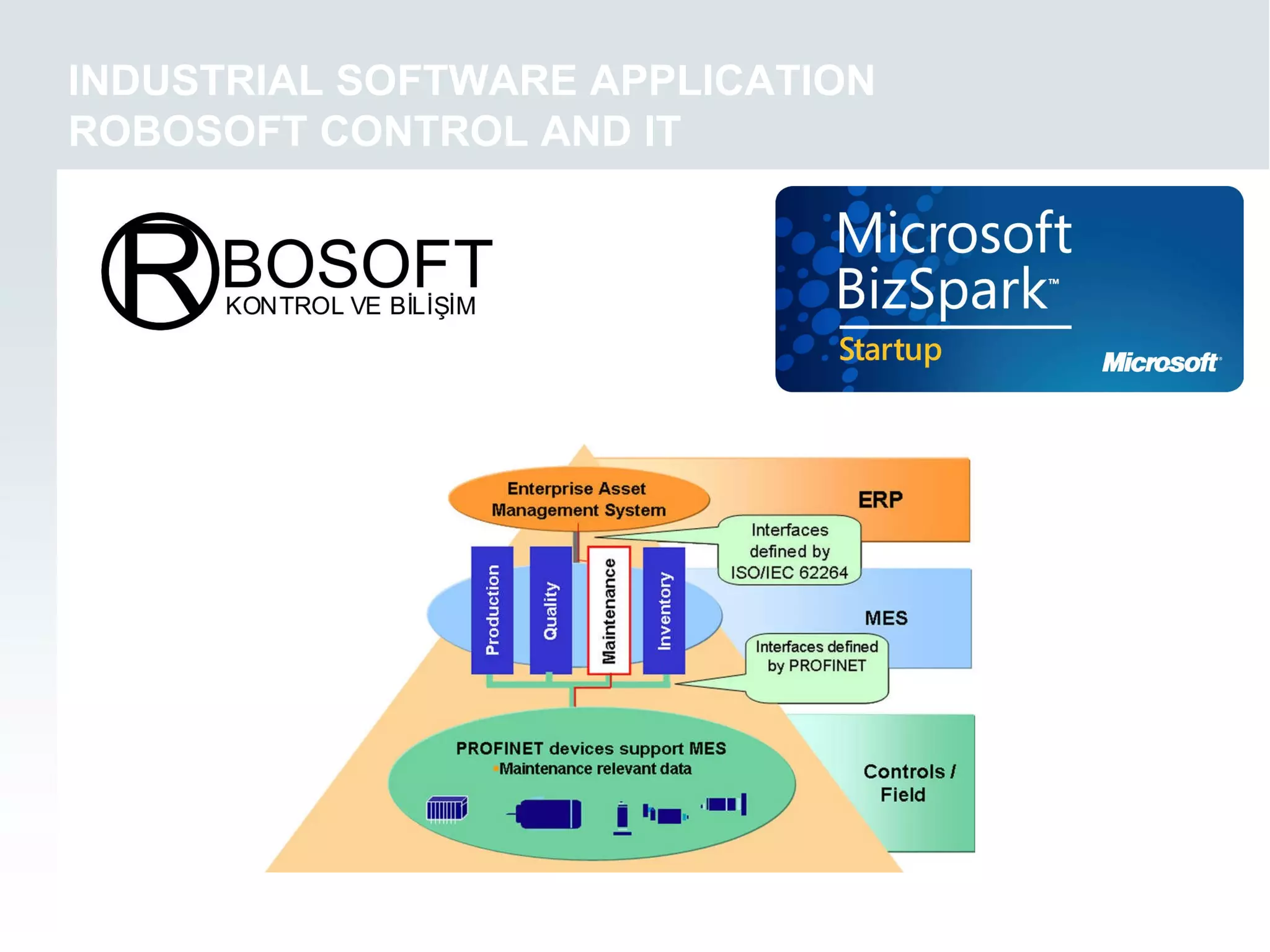

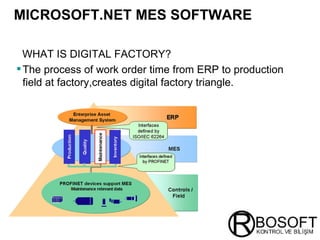

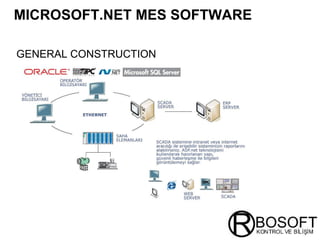

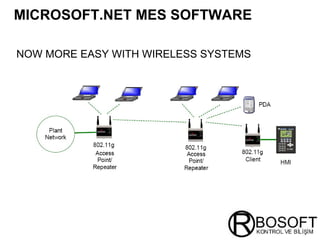

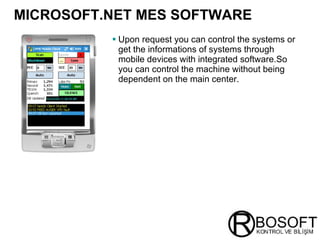

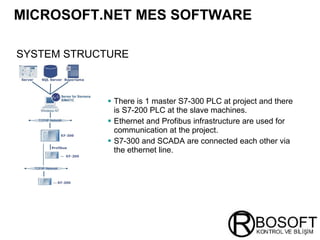

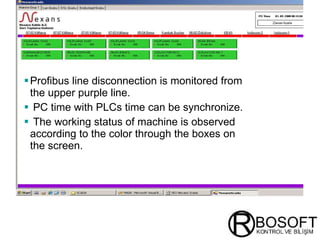

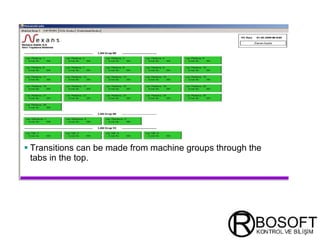

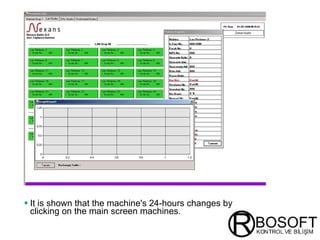

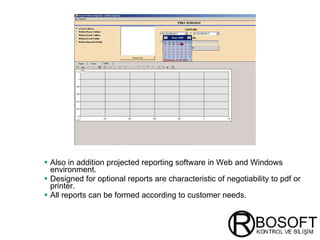

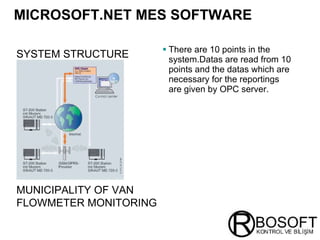

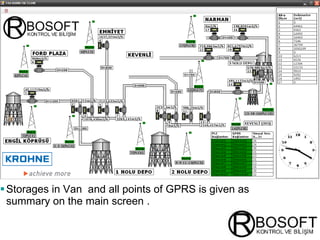

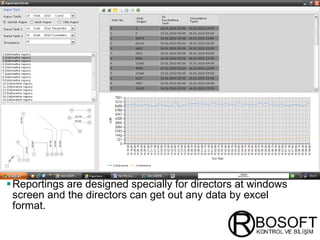

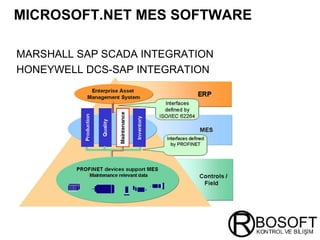

The document details the functionalities and applications of Microsoft .NET MES software, which serves as a Manufacturing Execution System (MES) that integrates factory operations with ERP systems. It highlights the benefits of real-time production tracking, inventory cost reduction, and customer-specific product generation, while also outlining features like remote monitoring and reporting capabilities. Additionally, it discusses specific project references that demonstrate the software's versatility across various industries, including automotive and municipality water monitoring systems.