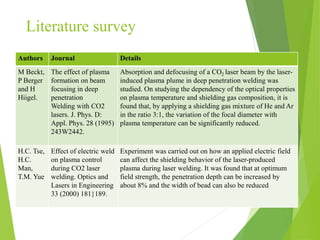

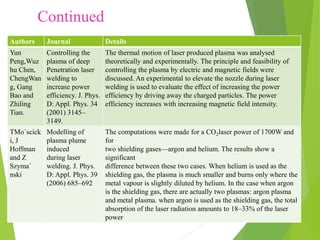

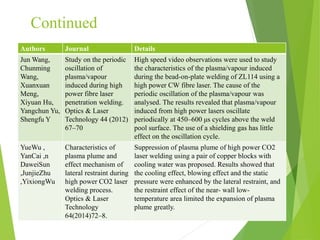

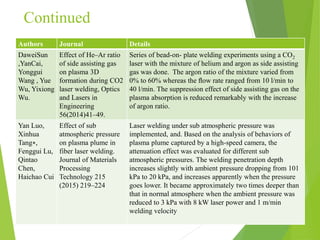

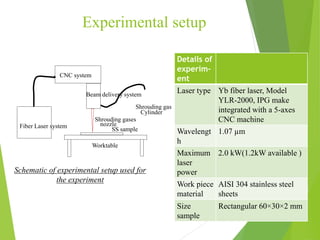

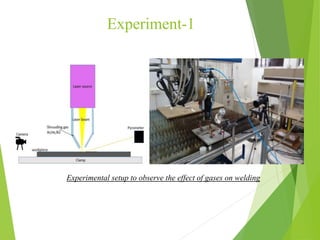

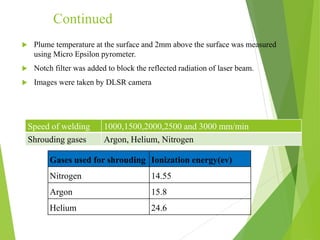

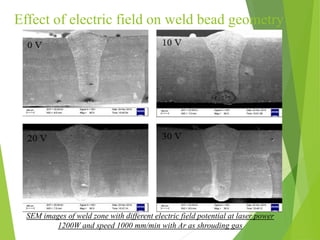

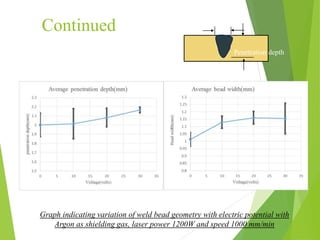

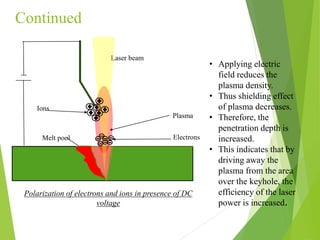

This document summarizes research on the effects of different shielding gases and electric fields on laser welding. It discusses how plasma forms during laser welding and can absorb and scatter the laser beam, reducing welding efficiency. The author conducted experiments using different shielding gases and applying electric fields to determine their effects on weld bead formation and address how plasma impacts the laser coupling. Literature on plasma modeling and methods to control plasma like side jets, magnetic fields, and sub-atmospheric pressures is also reviewed.

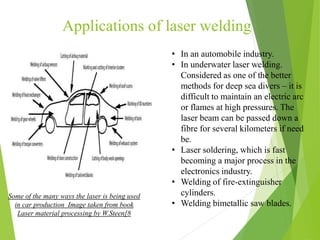

![Continued

Hermetically sealing Hermetically sealing

electronic capsules, which is possible

owing to the low HAZ, which is possible

owing to the low HAZ

Welding of polymers and plastics like

welding spectacles, diving suits, waders,

outdoor footwear, tents, parachutes and

soon carpets, bookbinding and injection

moulding.

Repair of nuclear boiler tubes from the

inside.

Welding transformer laminates to reduce

hum – the smaller weld zone reduces eddy

losses.

Hermetically sealed electronic capsules [Image link:

http://www.examiner.com/article/electronic-capsule-

prevents-gastrointestinal-disease]](https://image.slidesharecdn.com/fced3020-e69e-42b1-a44c-62130efcb96a-160803062857/85/presentation-6-320.jpg)

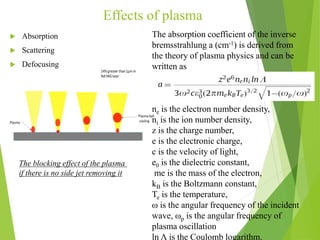

![References

[1] YueWu , YanCai ,n DaweiSun ,JunjieZhu ,YixiongWu. Characteristics of plasma

plume and effect mechanism of lateral restraint during high power CO2 laser welding

process. Optics & Laser Technology 64(2014)72–8.

[2] M Beckt, P Berger and H Hiigel. The effect of plasma formation on beam

focusing in deep penetration

Welding with CO2 lasers. J. Phys. D: Appl. Phys. 28 (1995) 243W2442.

[3] Yun Peng,Wuzhu Chen, ChengWang, Gang Bao and Zhiling Tian. Controlling the

plasma of deep

Penetration laser welding to increase power efficiency. J. Phys. D: Appl. Phys. 34

(2001) 3145–3149.

[4] H.C. Tse, H.C. Man, T.M. Yue. Effect of electric weld on plasma control during

CO2 laser welding. Optics and Lasers in Engineering 33 (2000) 181}189.](https://image.slidesharecdn.com/fced3020-e69e-42b1-a44c-62130efcb96a-160803062857/85/presentation-34-320.jpg)

![References

[5] Y. Kawahito*, N. Matsumoto, M. Mizutani and S. Katayama. Characterisation

of plasma induced during high power fibre laser welding of stainless steel. Science

and Technology of Welding and Joining 2008 VOL 13 NO 8

[6] DaweiSun ,YanCai, Yonggui Wang , Yue Wu, Yixiong Wu.Effect of He–Ar ratio

of side assisting gas on plasma 3D formation during CO2 laser welding, Optics and

Lasers in Engineering 56(2014)41–49.

[7] 402935-LASERLINE Technical Laser Welding AW.indd. 17/08/2009.

[8] William M. Steen , Jyotirmoy Mazumder. Laser Material Processing. Springer-

Verlag London Limited 2010

[9]Kawahito Yousuke , Mizutani Masami and Katayama Seiji. Optical density

interaction between laser beam and induced plasma in ultra-high power fiber laser

welding of stainless steel, Transactions of JWRI, vol.37 (2008), No.2](https://image.slidesharecdn.com/fced3020-e69e-42b1-a44c-62130efcb96a-160803062857/85/presentation-35-320.jpg)