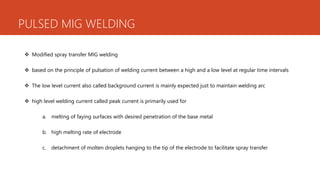

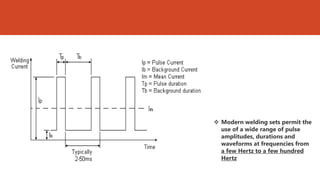

Pulsed MIG welding is a modified spray transfer welding process where the welding current is pulsed between a high peak current and a low background current at regular intervals. This pulsation allows for detachment of uniform molten droplets from the electrode wire. Pulsed MIG welding offers advantages like wire and gas savings, reduced spatter, improved productivity, and the ability to weld a wider range of metals. While offering these benefits, pulsed MIG welding also requires more expensive equipment and shielding gases compared to conventional MIG welding. It finds applications in welding of structural steel, aluminum, stainless steel, and some offshore applications.