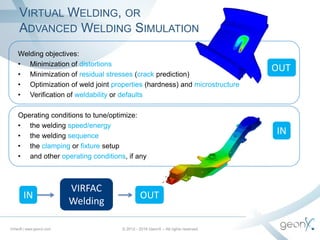

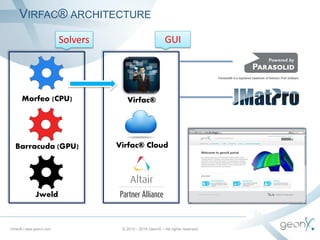

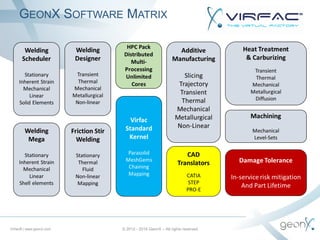

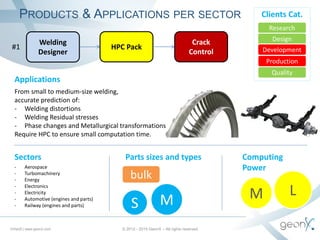

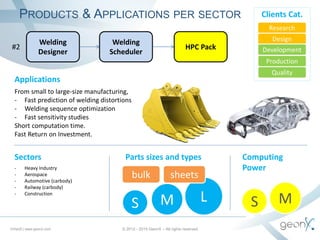

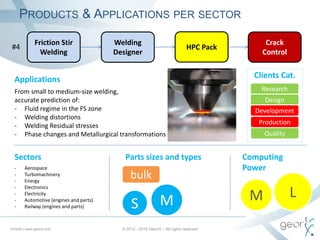

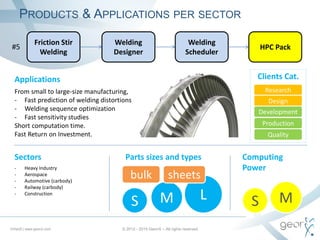

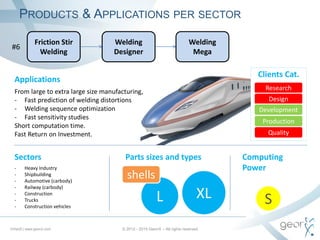

Virfac® is an advanced welding and heat treatment simulation software designed to minimize distortions and residual stresses while optimizing weld joint properties. It caters to various sectors including aerospace, automotive, and heavy industry by providing fast predictions and sensitivity studies for different manufacturing sizes. The software emphasizes computational efficiency and offers tailored applications for small to extra-large manufacturing needs.