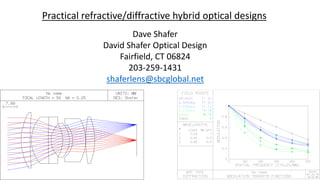

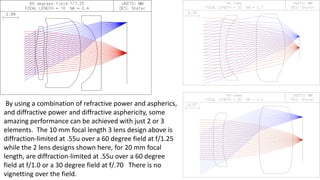

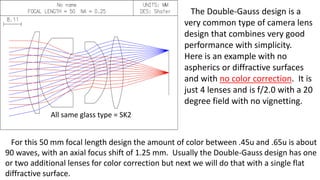

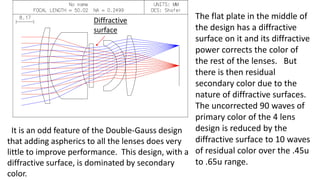

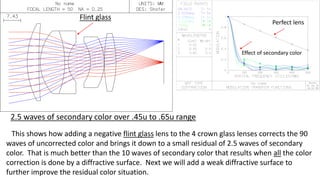

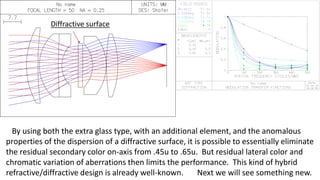

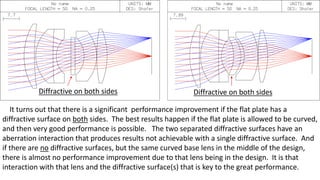

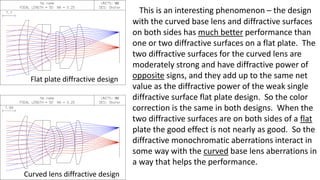

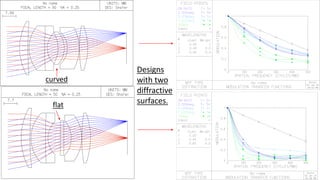

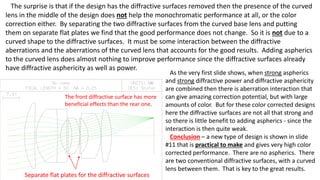

The document discusses advanced optical designs that combine refractive and diffractive elements to achieve high performance with minimal aberrations. It highlights the limitations of simple designs and emphasizes a new hybrid approach using curved lenses and dual diffractive surfaces for improved color correction and overall effectiveness. The findings indicate that the interaction between different aberration types can significantly enhance performance in practical optical systems.