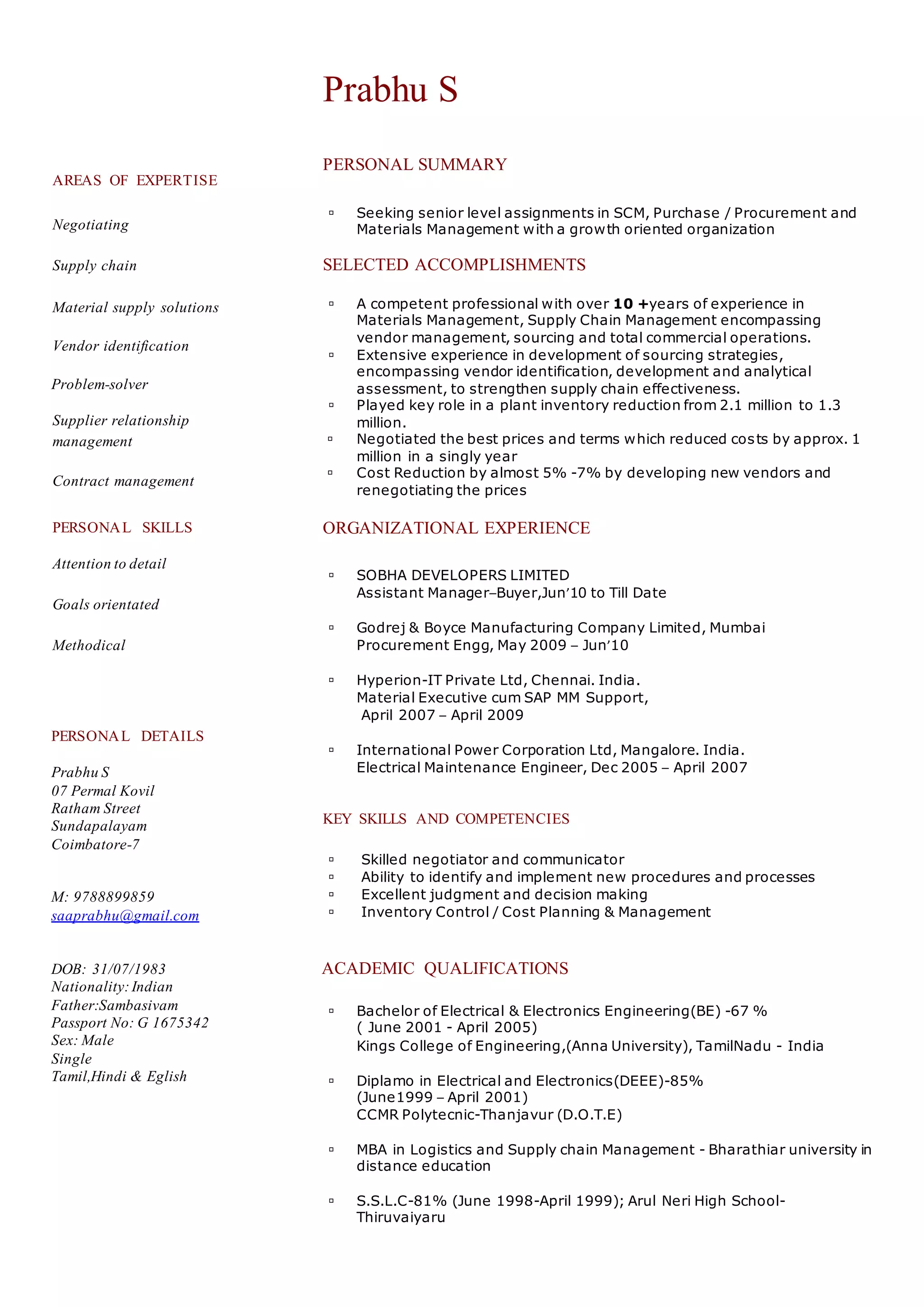

This document provides a summary of Prabhu S's professional experience and qualifications. It outlines his expertise in areas such as supply chain management, procurement, and materials management. Prabhu has over 10 years of experience in these fields, having worked for companies such as Sobha Developers, Godrej & Boyce Manufacturing, Hyperion IT, and International Power Corporation. The document details his responsibilities and accomplishments in roles such as Assistant Manager of Procurement and Materials Executive. It also lists his educational qualifications, including a bachelor's degree in electrical engineering and an MBA in logistics and supply chain management.

![ Negotiations with suppliers to get a best deal and spend Procurement spend base - Approx. INR 100 C per

fiscal year

Review requisition orders in order to verify accuracy, terminology, and specifications

Ensuring timely delivery of material from supplier to site/ warehouse as per the schedule

Development of new vendors to achieve cost reduction and minimize lead time.

Prepare, maintain, and review purchasing files, reports and price lists.

issue purchase orders promptly on basis of approved quotation summaries

Monthly Planning and Scheduling of material as per the Quarterly plans received

Working in co-ordination with Development team for development of alternate vendors/ parts for the

purpose of cost reduction

Locate suppliers, using sources such as catalogs and the internet, and interview them to gather information

about products to be ordered.

Manage purchasing and inventory control functions

COMPANY: Hyperion It Pvt Ltd

CLINT: Reliance Industries Limited, Navi Mumba

Project 1: Krishna Godavari Development Project E&P

(Exploration and Production)

Synopsis ofactivities done

Codifying the KGD-6 (Krishna Godavari Development) materials to execute Petrochemical Business

Verifying and Analyzing Final Documents including MDR (Manufacturer Record) Book and Analyzing

spares details in Data sheet, GA drawings, Cross section Drawings for Technical reference of Equipments

while Maintenance.

Verification & approval of Operation and Maintenance manual for Technical Operations of the

Equipments. And Consolidated MIS report for the supply bases for performance evaluation generation

every fortnight

Regular monitoring of inventory level and planning for minimum inventory possible

Receiving the BOM (Bill Of Material) for a product from customer, processing the RFQ & sending it to

Customer AML(Approved Manufacturer List)

Procuring the requirement of the materials like All types of Valves Transmitters, Pressure Gauge and

including piping items and electrical items

Analyzing quotations as regards to Price, Lead time, MOQ etc

Analyzing SPIR (Spare Parts Interchangeability Record) a Typical Bechtel-Reliance Format of Spares

Details gives a clear picture of Material Movements on SAP Entry Works.

Creation of Material Master records Set the Deletion flag for the material code under the requisition.

Inspection setup maintain for incoming material.

Coordination for the supply bases requirement planning at the HO & processing of the same in SAP

COMPANY: International Power Corporation Ltd Project 1: 3 X 6 MW Mini Hydel Power Project

Synopsis ofactivities done:

Involved in Trouble shooting and maintenance of indoor switchgears 11/66 K.V & 415 v panels.

Involved in Trouble shooting of power Transformers, Current Transformers, Potential Transformers,

Capacitor Voltage Transformers, and Circuit Breakers up to 220 K.V Systems. And Involved in Trouble

shooting of all Tripping Relays, Electro Mechanical Relays, Static Relays and Numerical Relays

Skilled in analyzing Single Line Diagram, Control Circuit & Interlocking Scheme etc.

Declaration:

I hereby states that all the above information is True and correct. I will be grateful to work with your

Esteemed Organization to accelerate my Skills with my expertise Technicalities and with my good

Teamwork capacity

Yours Sincerely,

Date: [Prabhu.s]](https://image.slidesharecdn.com/65fa9fbc-46bb-4141-b8ea-5d8b7980f1bd-160116064606/85/Prabhu-New-CV-3-320.jpg)