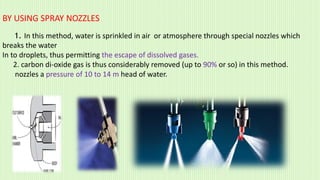

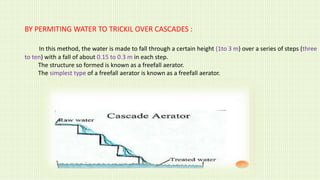

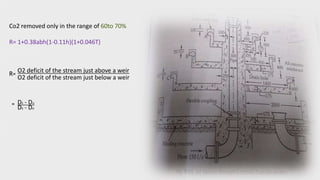

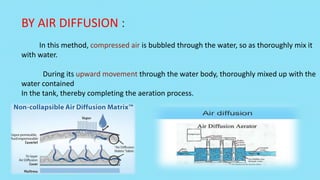

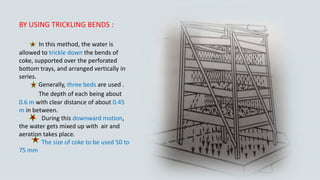

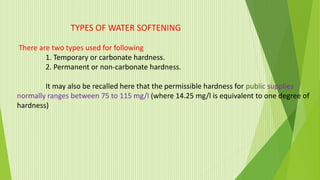

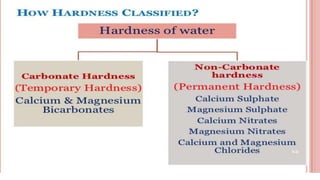

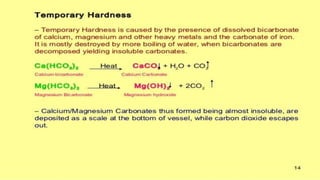

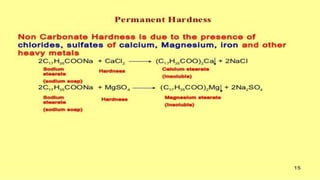

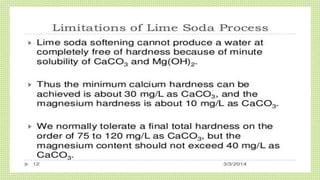

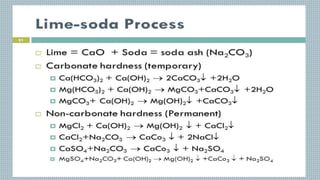

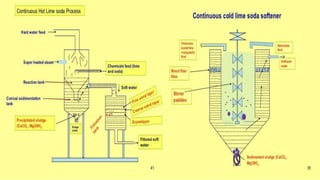

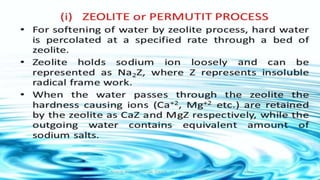

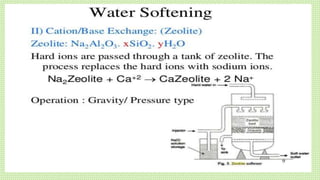

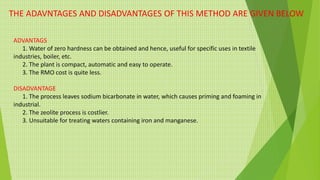

This document discusses various methods for removing colors, odors, tastes, iron, and manganese from water, as well as treatments for temporary and permanent water hardness. It describes processes like aeration, spray nozzles, trickling beds, and air diffusion to remove gases from water. Methods for iron and manganese removal include oxidation. For water softening, it discusses lime-soda, zeolite, and demineralization processes to treat temporary and permanent hardness. The advantages of these treatments are more palatable water and reduced scaling, while disadvantages include cost and sodium byproducts.