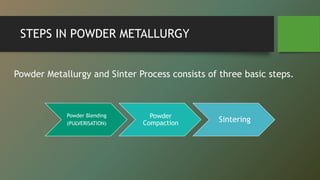

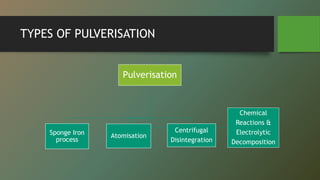

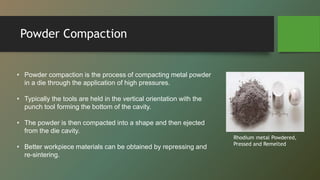

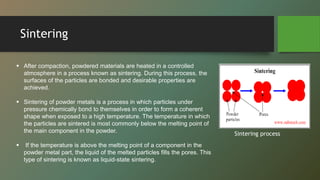

Powder metallurgy involves three basic steps: 1) Pulverisation is the process of applying force to reduce solid materials into smaller powder particles, which can be done through various techniques like crushing or chemical reactions; 2) Powder compaction involves compacting metal powders in a die under high pressure to form shapes; 3) Sintering is the final heating process where the powder particle surfaces bond to form a coherent shape below melting point through chemical reactions, or it can involve liquid phase sintering if a component melts above its melting point.