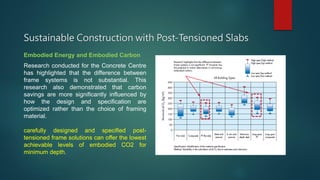

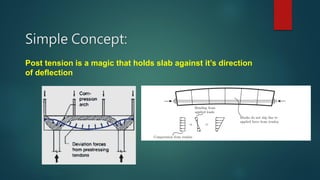

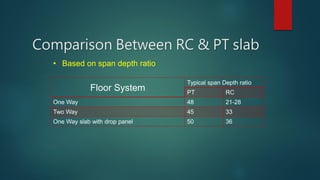

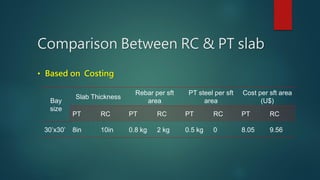

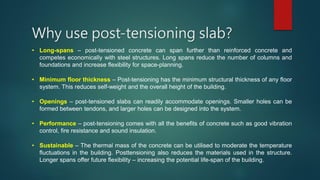

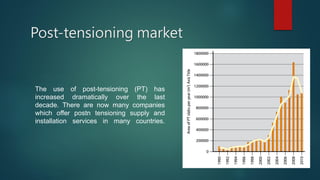

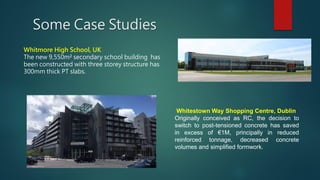

This document provides an overview of post-tensioned concrete slabs. It discusses how PT slabs use high-strength steel strands in tension to compress the concrete and allow for thinner slab thicknesses. This makes PT slabs more efficient and economical compared to reinforced concrete, allowing for longer spans. Examples are given showing how PT slabs offer reductions in material usage, embodied carbon, and cost. Case studies demonstrate real-world applications of PT slab construction.