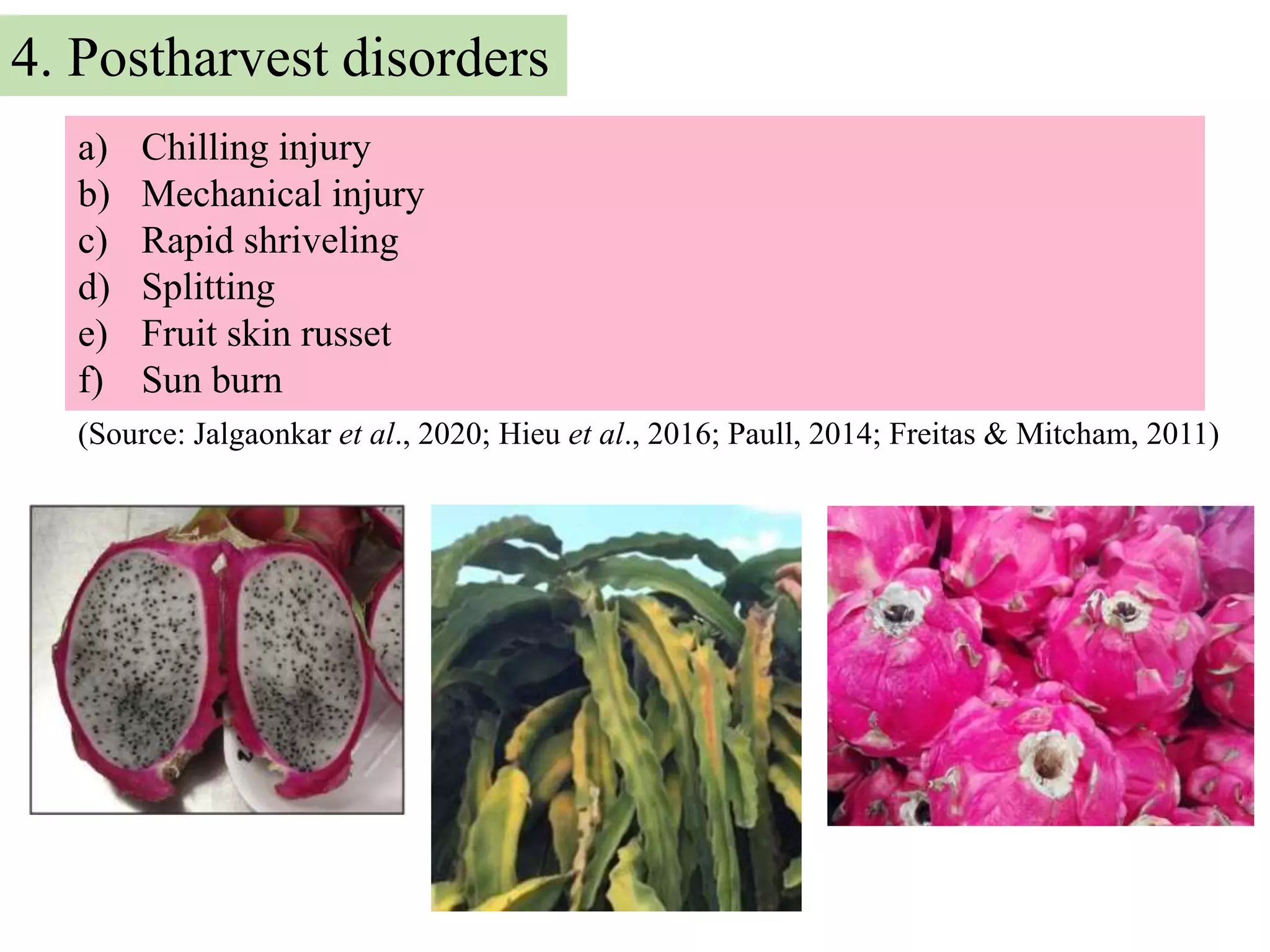

The document discusses post-harvest management and marketing strategies for dragon fruit, focusing on challenges like its perishability and the impact of harvesting techniques on quality. It outlines grading, packaging, and storage methods to reduce losses and highlights value-added products and potential market opportunities. Recommendations for off-season production and the importance of research for improving fruit quality and enhancing farmers' income are emphasized.