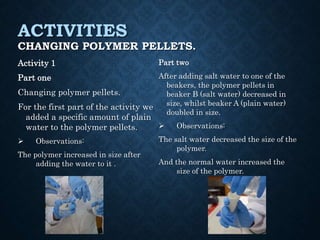

The document discusses various activities related to the study of polymers, including changing polymer pellets, comparing viscosities, and testing tensile strength. It details the design of a humidity-sensing packaging material aimed at preventing food spoilage in high-humidity conditions, particularly for items like dates. The conclusion emphasizes the potential applications of the humidity sensor in various food packaging scenarios and acknowledges the support received during the project.