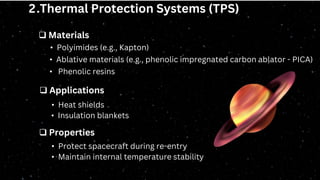

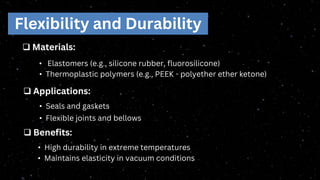

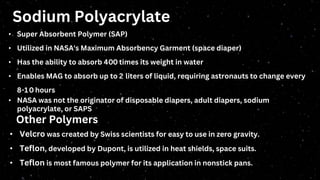

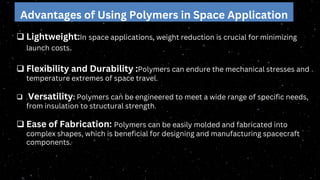

The document discusses the application of polymers in space technology, highlighting their essential properties such as thermal stability, radiation resistance, and mechanical strength. It lists various applications including thermal blankets, electrical components, and structural components, emphasizing materials like carbon fiber-reinforced polymers and polyimide films. The document also addresses the advantages of using polymers, including their lightweight nature and versatility, along with challenges like outgassing and radiation resistance.

![Polymer_Application_in_sbBpace[1]23.pptx](https://image.slidesharecdn.com/polymerapplicationinspace123-240703071750-8b0179bd/85/Polymer_Application_in_sbBpace-1-23-pptx-16-320.jpg)