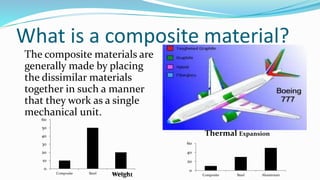

Composite materials are made by combining two or more dissimilar materials to take advantage of their combined properties. They consist of a matrix phase that binds together the dispersed phase to form a single mechanical unit. Composites offer advantages over traditional materials like metals and polymers, including higher strength and stiffness for a given weight, better corrosion and heat resistance, and easier fabrication. Common applications of composites include use in vehicles, sports equipment, electronics and construction.

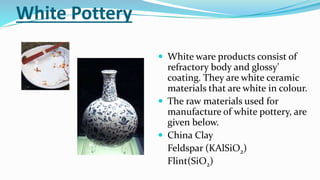

![MANUFACTURE OF WHITE POTTERY

Step I Preparation of

body ware

The raw materials Kaoline

[Al (OH)4 SiO5] and

Feldspar are made into fine

powder and mixed with

water to form a creamIt is

dried and then fired in a

'biscuit' oven to get porous

ware called 'Bisque’](https://image.slidesharecdn.com/unit-iv-150313110101-conversion-gate01/85/Poly-chemIV-9-320.jpg)