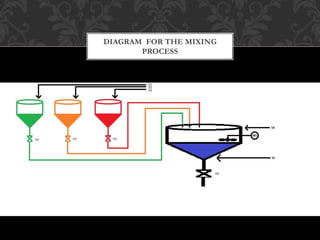

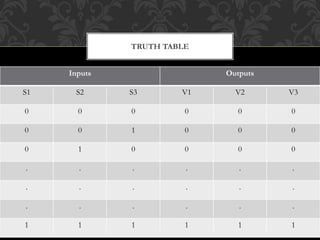

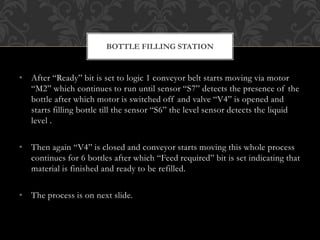

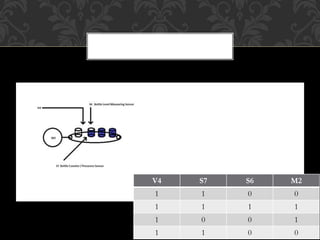

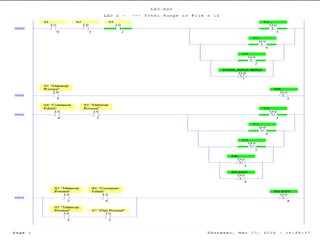

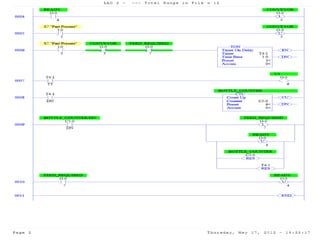

The document describes an industrial mechatronics project to design a material mixing and bottle filling station. There are three containers with level sensors that determine when material is present, and their valves open to fill a large mixing container. That container has sensors to determine the upper and lower material levels, and a motor mixes the material until the upper level is reached. A "Ready" signal then indicates the material can be filled into bottles on a conveyor belt, which runs until a bottle is detected by a sensor and the valve opens to fill it, closing once the bottle's level sensor is triggered. This process repeats for six bottles before a "Feed required" signal notes the material needs refilling.