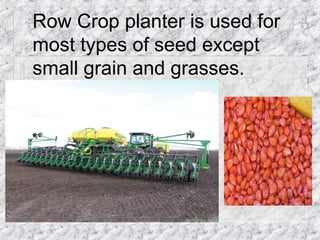

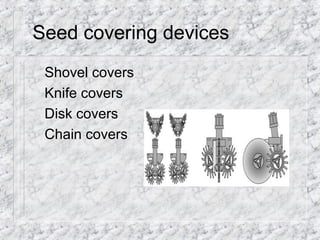

This document discusses planting equipment. It describes the basic functions of planters as opening a furrow, metering and placing seeds, and covering seeds. The main types of planting equipment are identified as row-crop planters, grain drills, broadcast seeders, and specialized planters. The components of row-crop planters discussed include frames, drives, furrow openers, seed metering devices, seed placement mechanisms, and depth control devices. Solid planting equipment components include grain drills and their types. Calibration and maintenance of planting equipment are also covered.