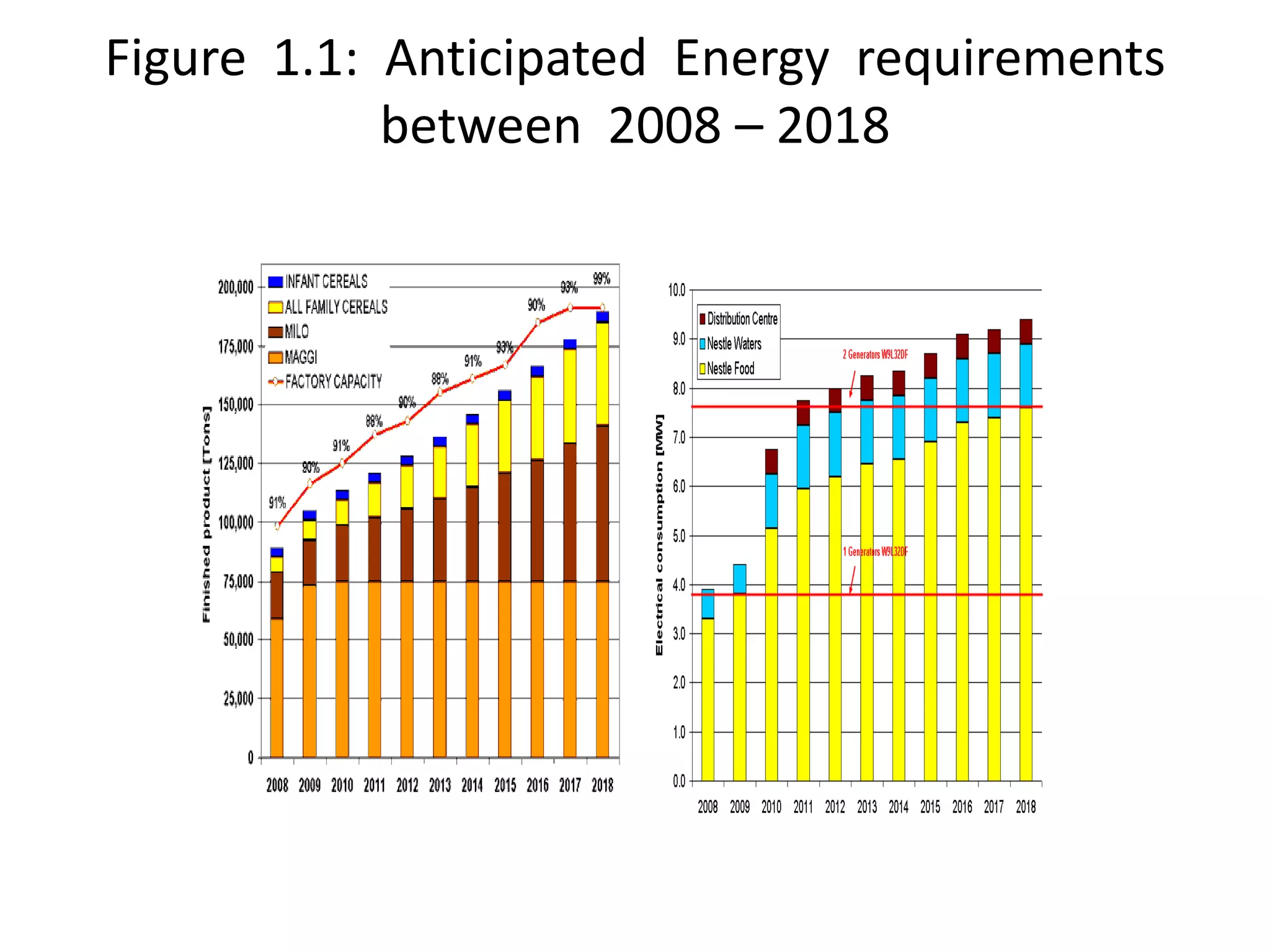

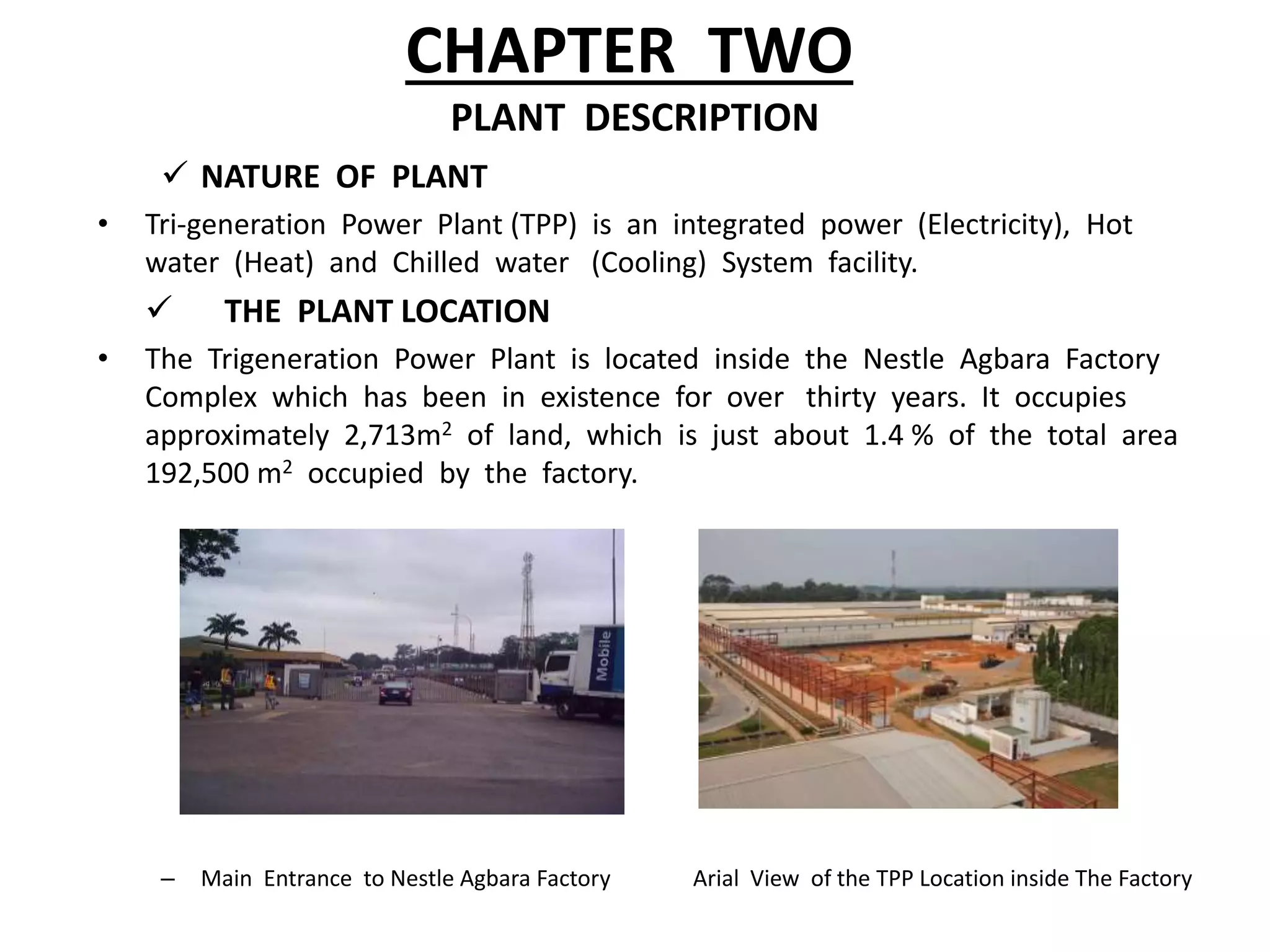

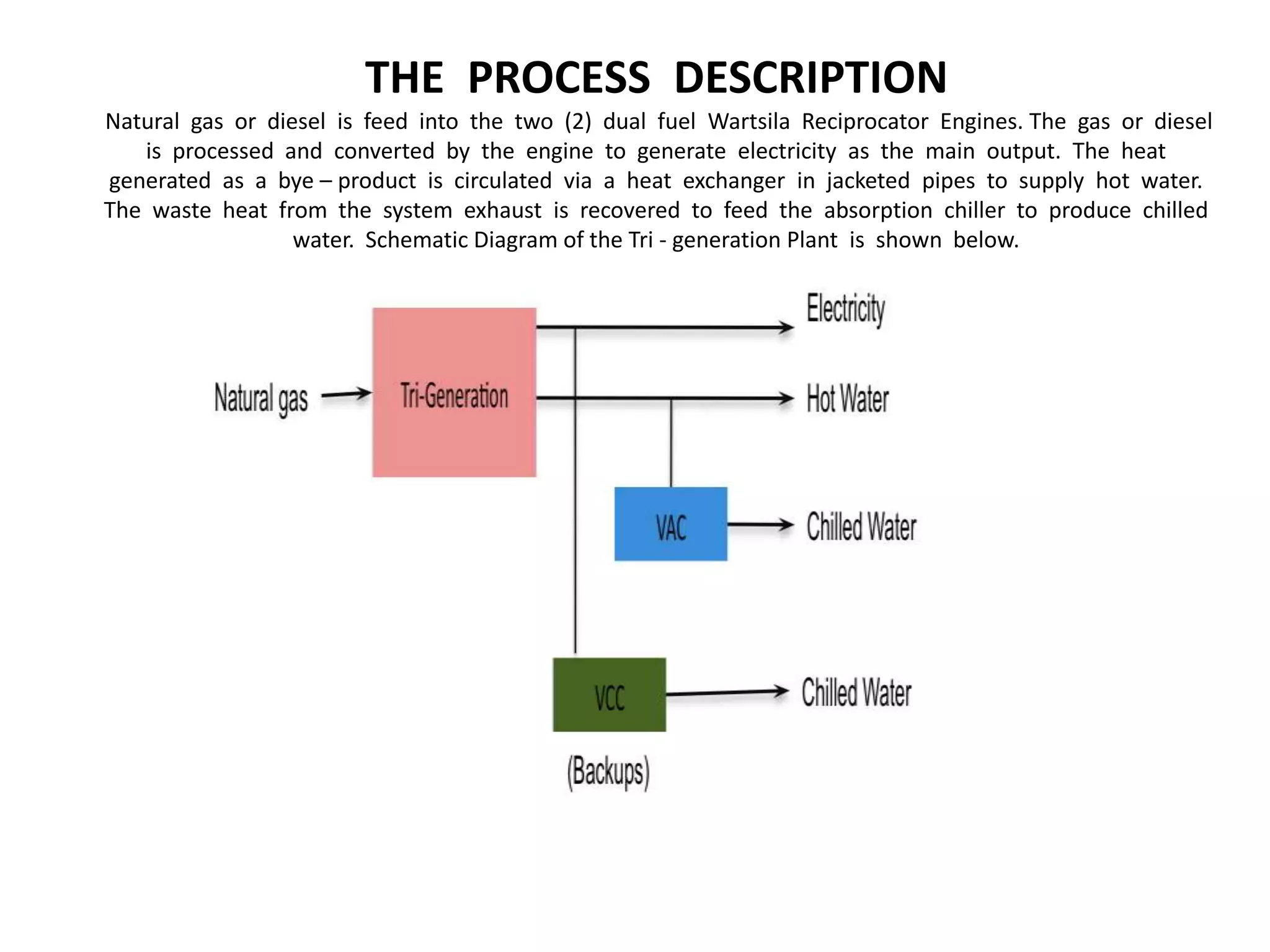

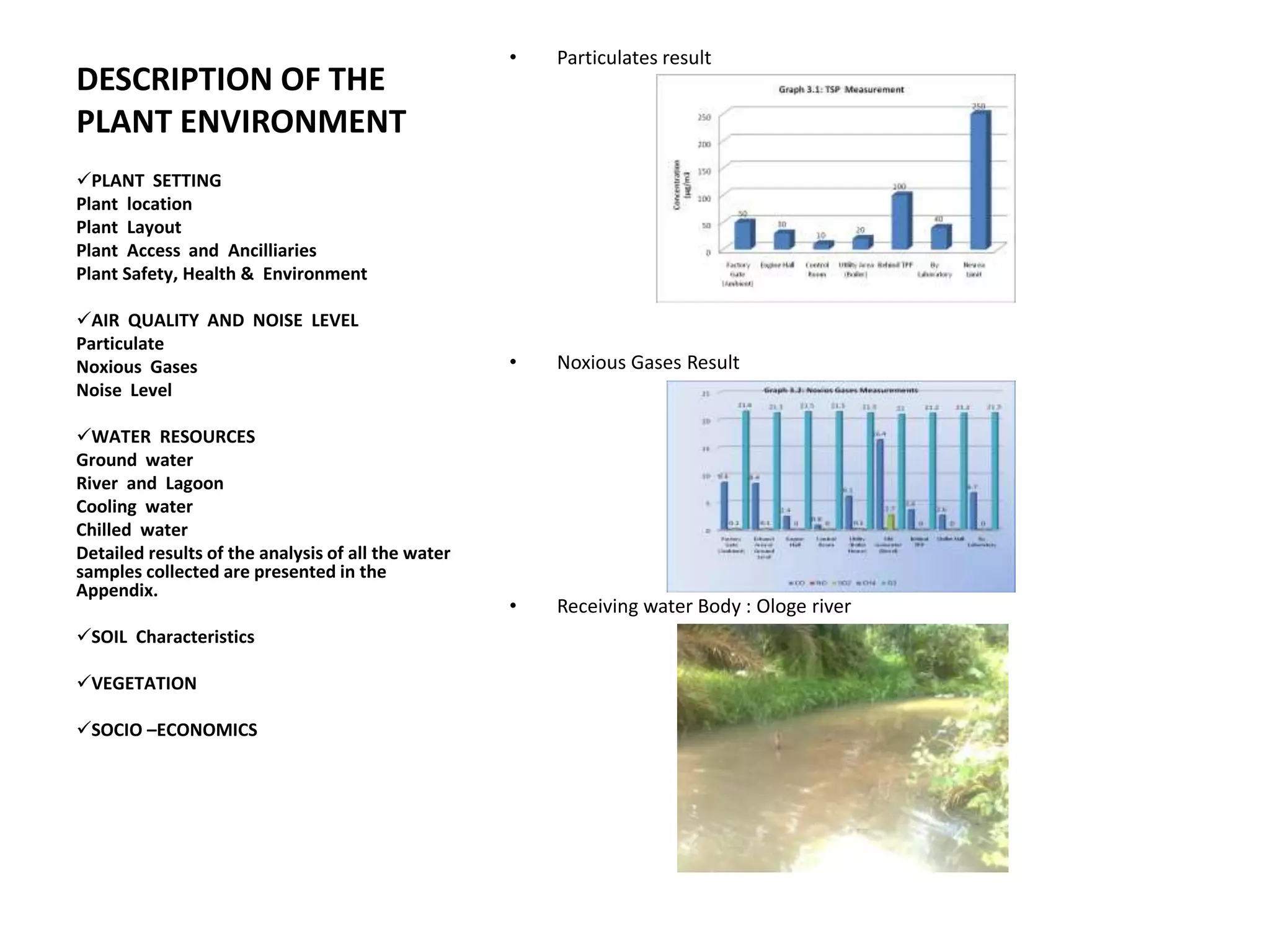

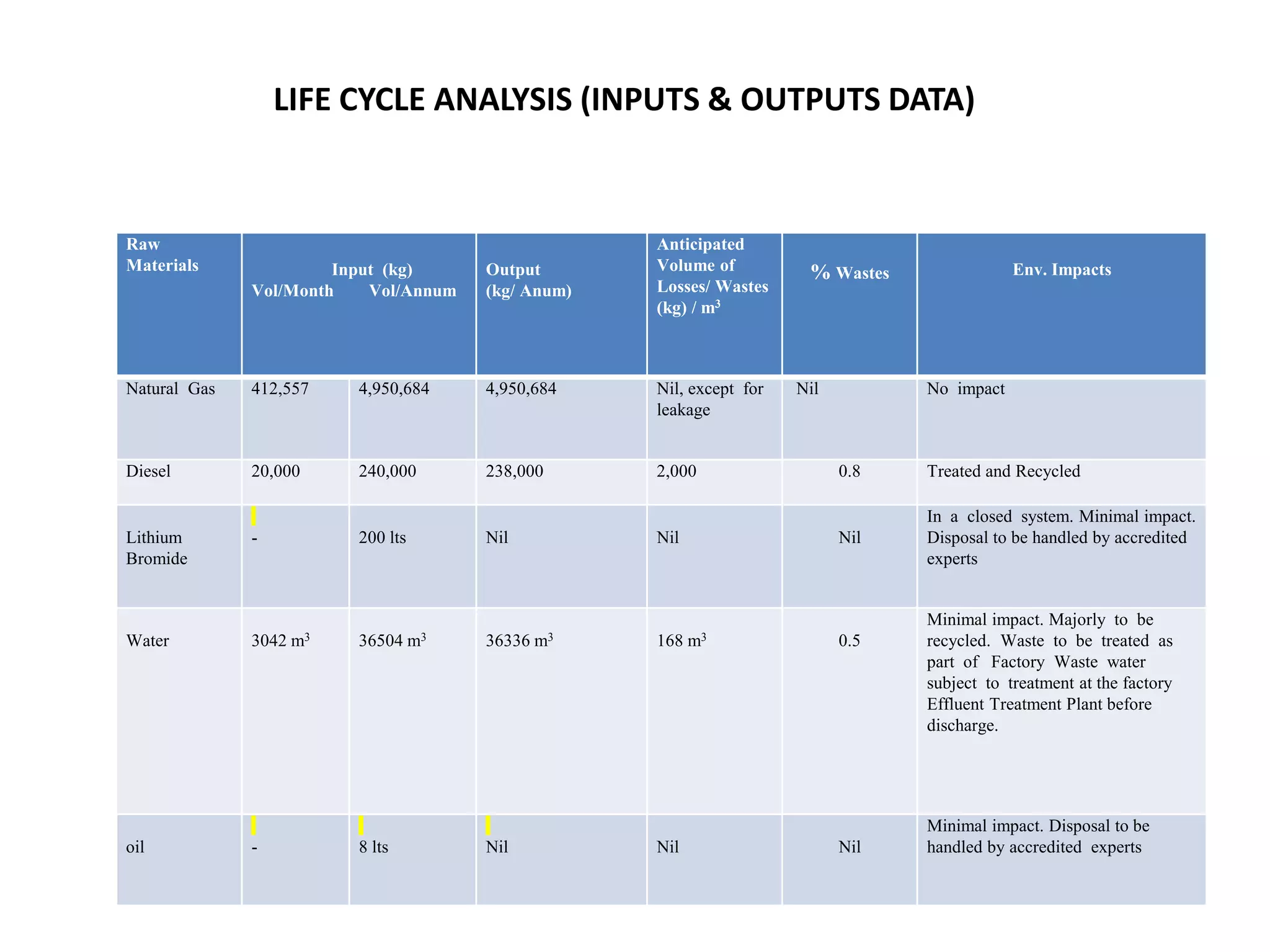

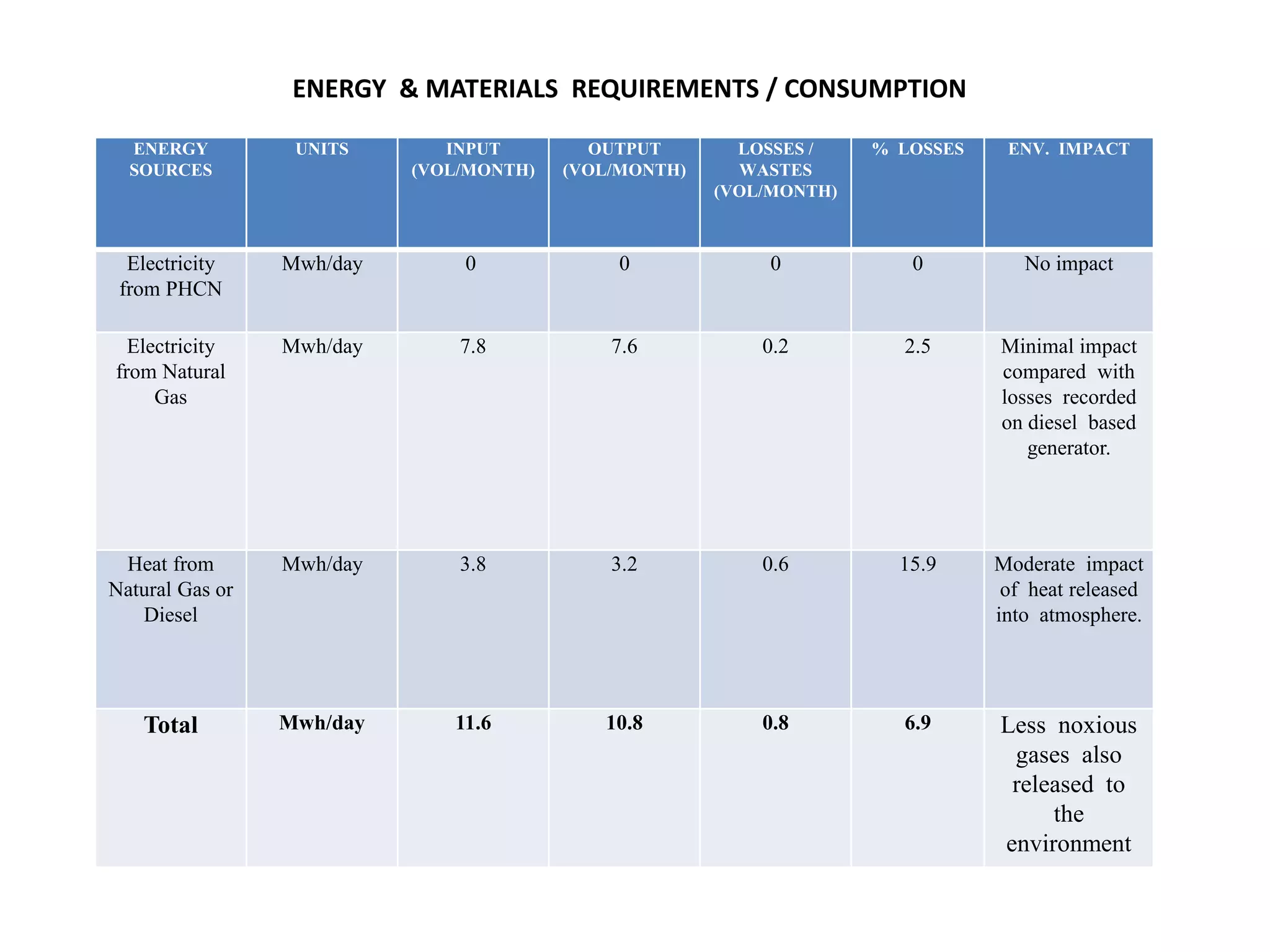

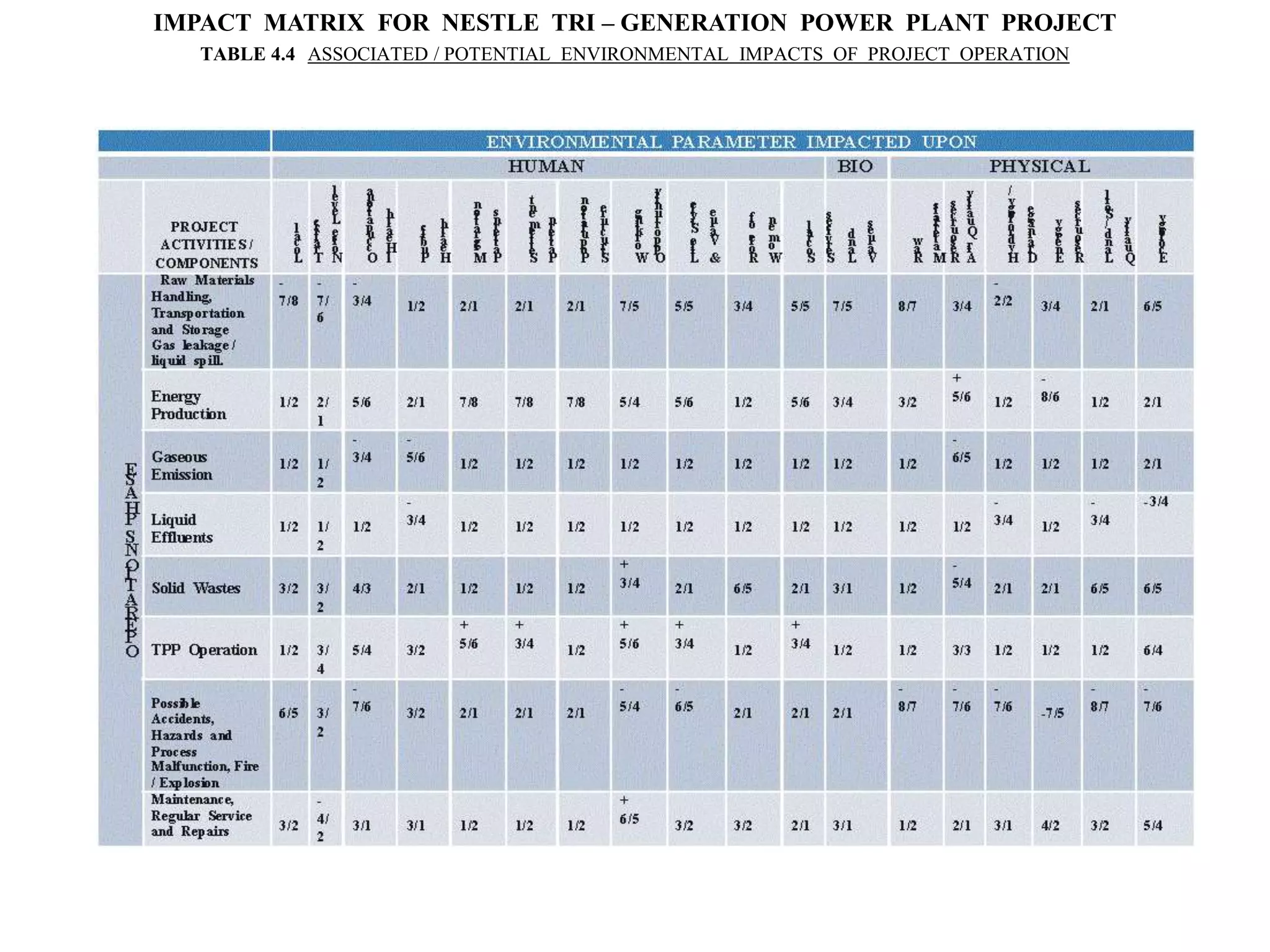

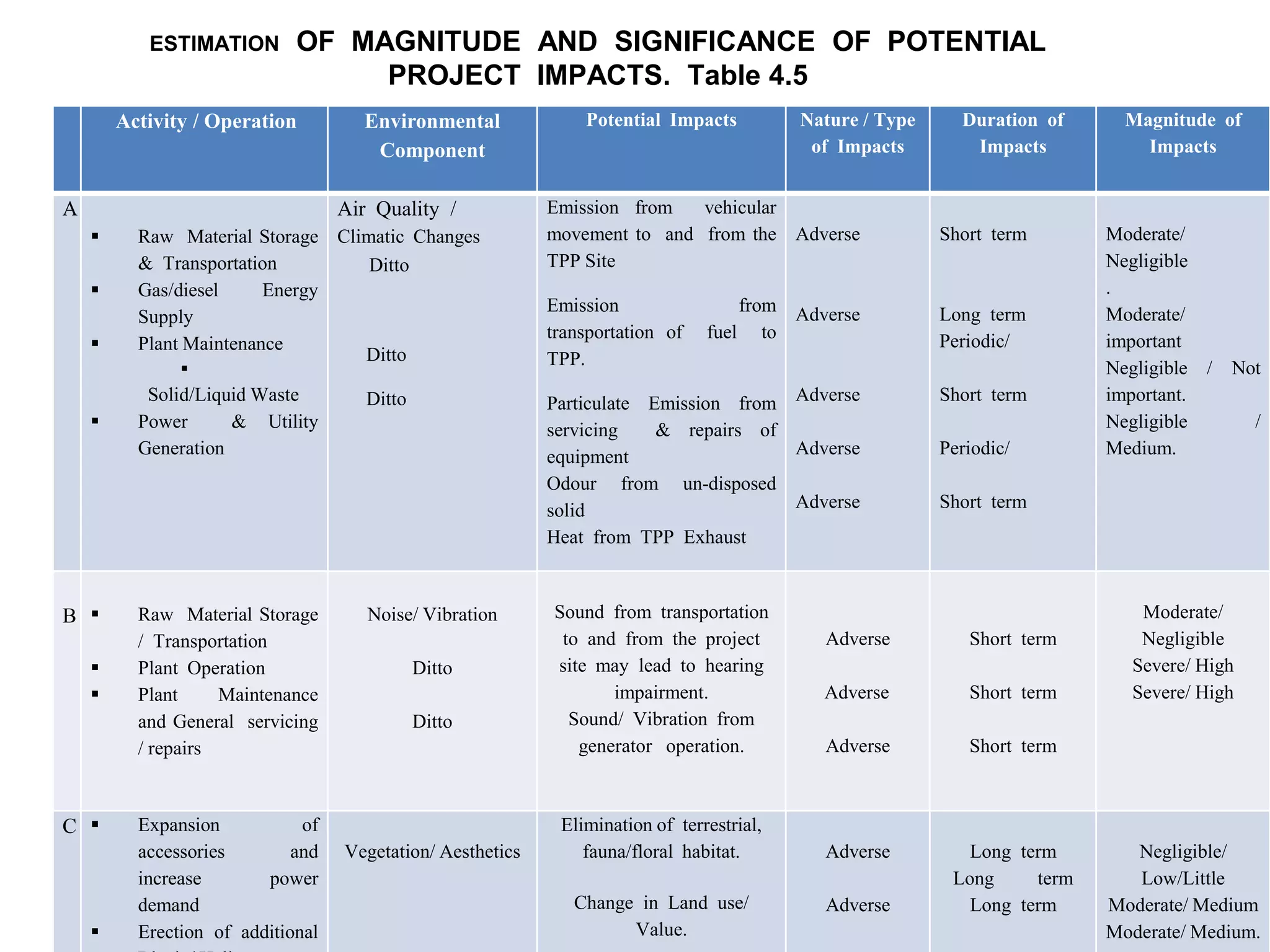

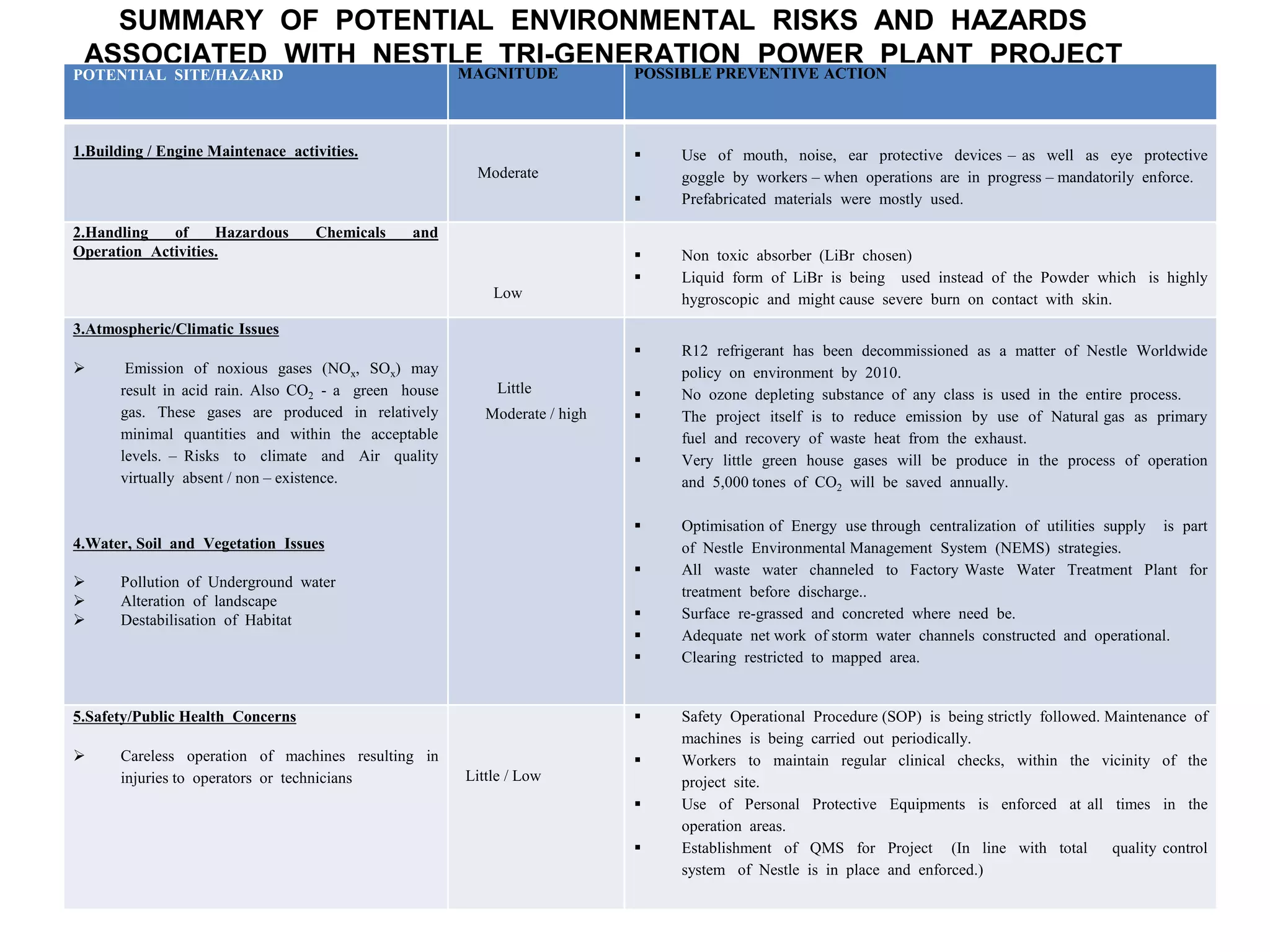

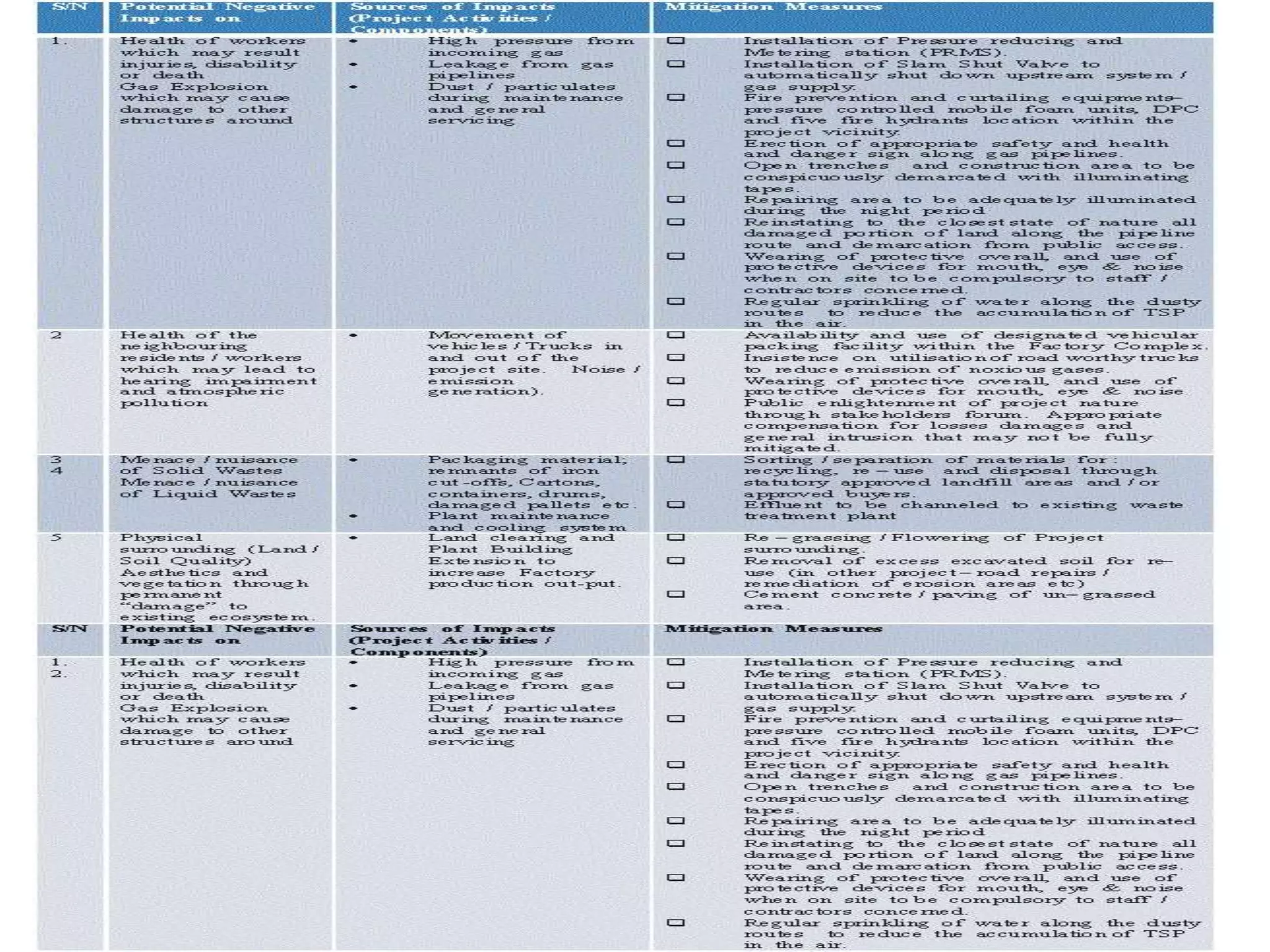

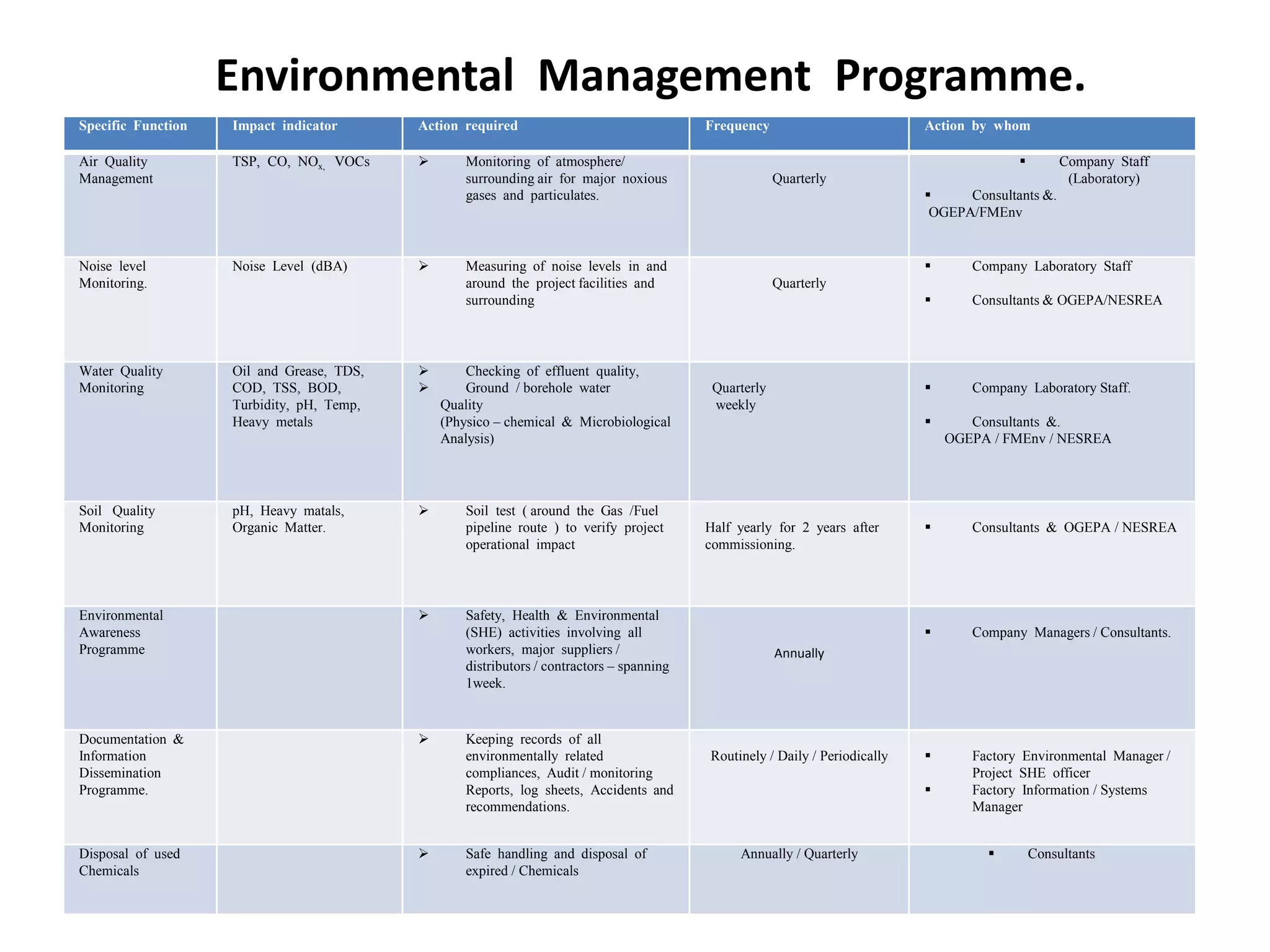

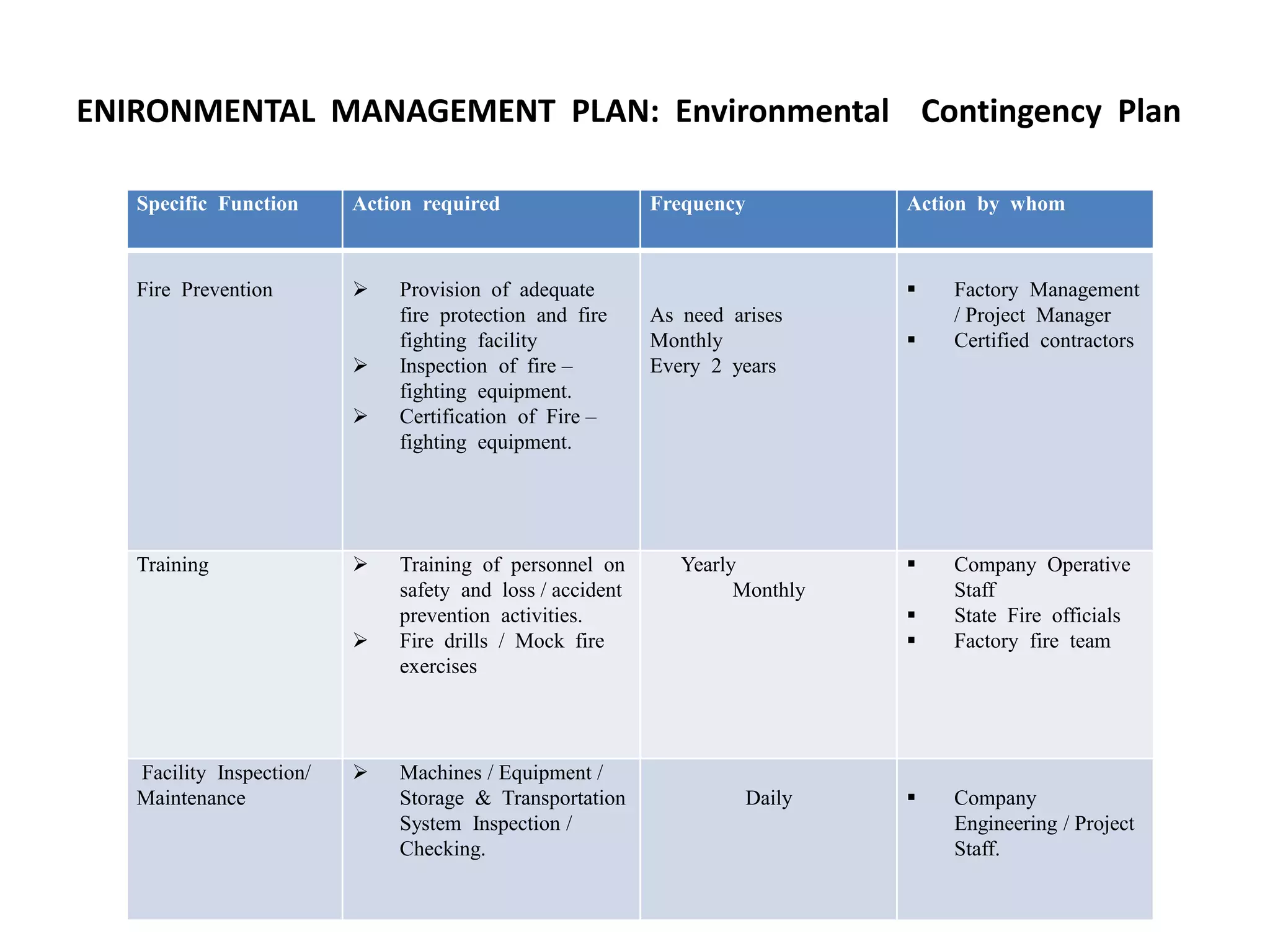

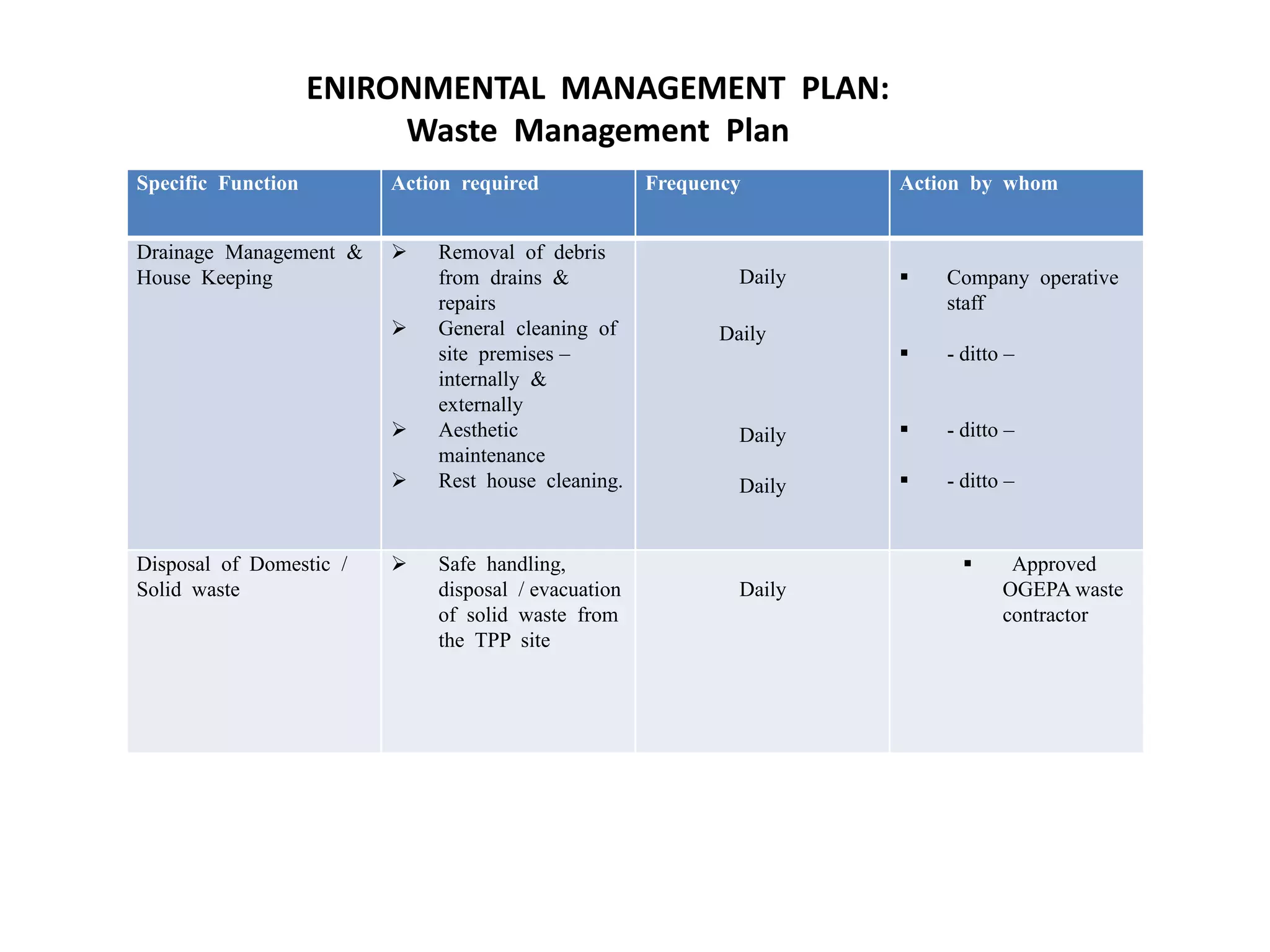

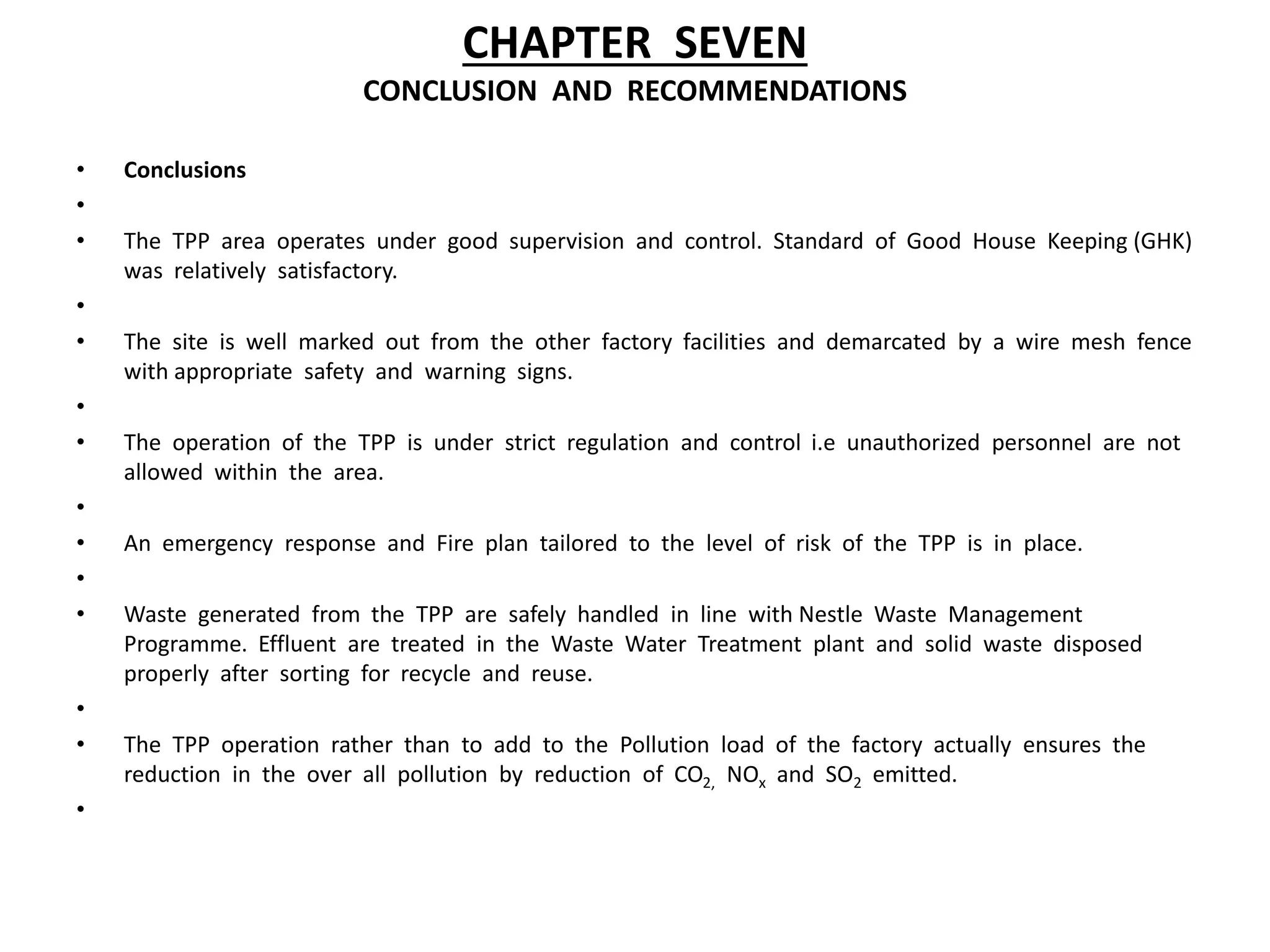

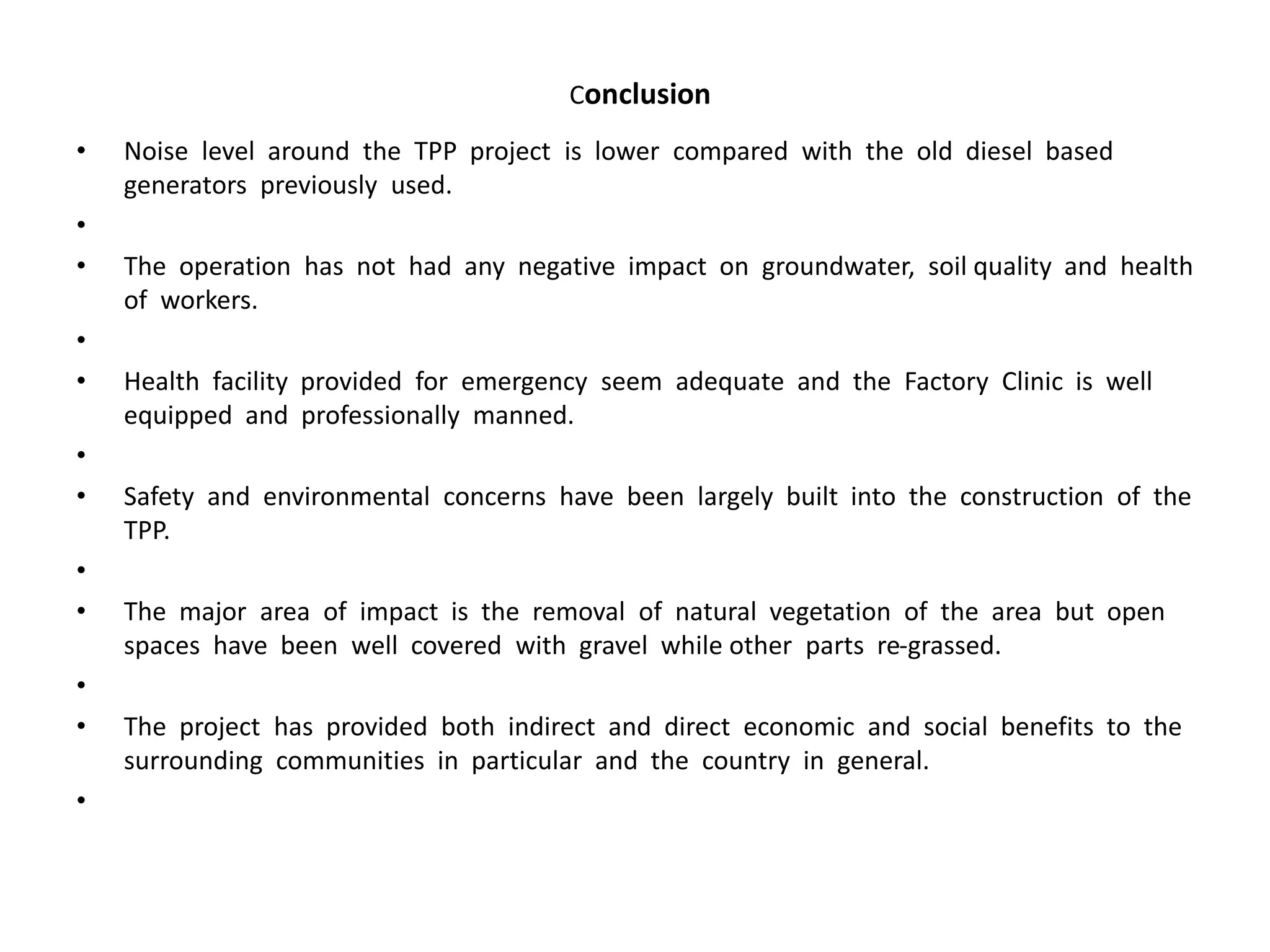

This document provides a summary of a post impact assessment report for Nestle's tri-generation power plant. The report includes chapters on plant description, environmental impacts, mitigation measures, and environmental management plan. Key findings are that the power plant is expected to reduce greenhouse gas emissions and improve electricity supply stability. Impacts on air and water quality are assessed, along with waste generation and management. The study was conducted over two months to evaluate the plant's environmental performance and compliance with regulations.