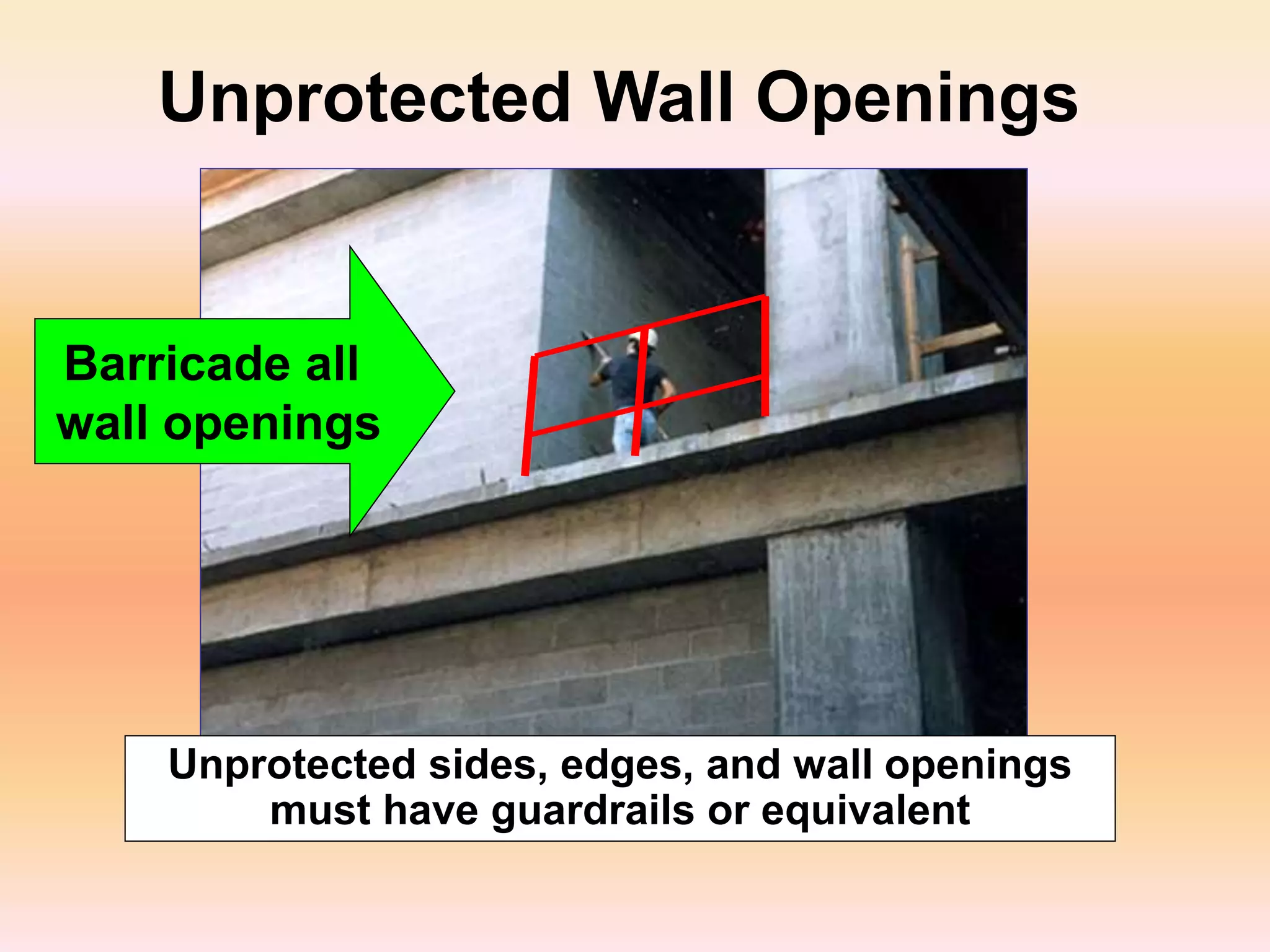

This document provides guidance on fall protection when working at heights. It outlines that falls are a leading cause of death in construction and that fall protection measures should follow a hierarchy of first removing hazards, then using passive barriers like guardrails if work at heights is necessary, and if those are not possible using fall restraint or arrest systems. It details requirements for guardrails, safety nets, harnesses and other fall protection equipment. Situations requiring fall protection include various elevated work areas, openings, excavations and mobile equipment. Ladders, stairs and scaffolding must also be properly constructed and used to prevent falls from any height.