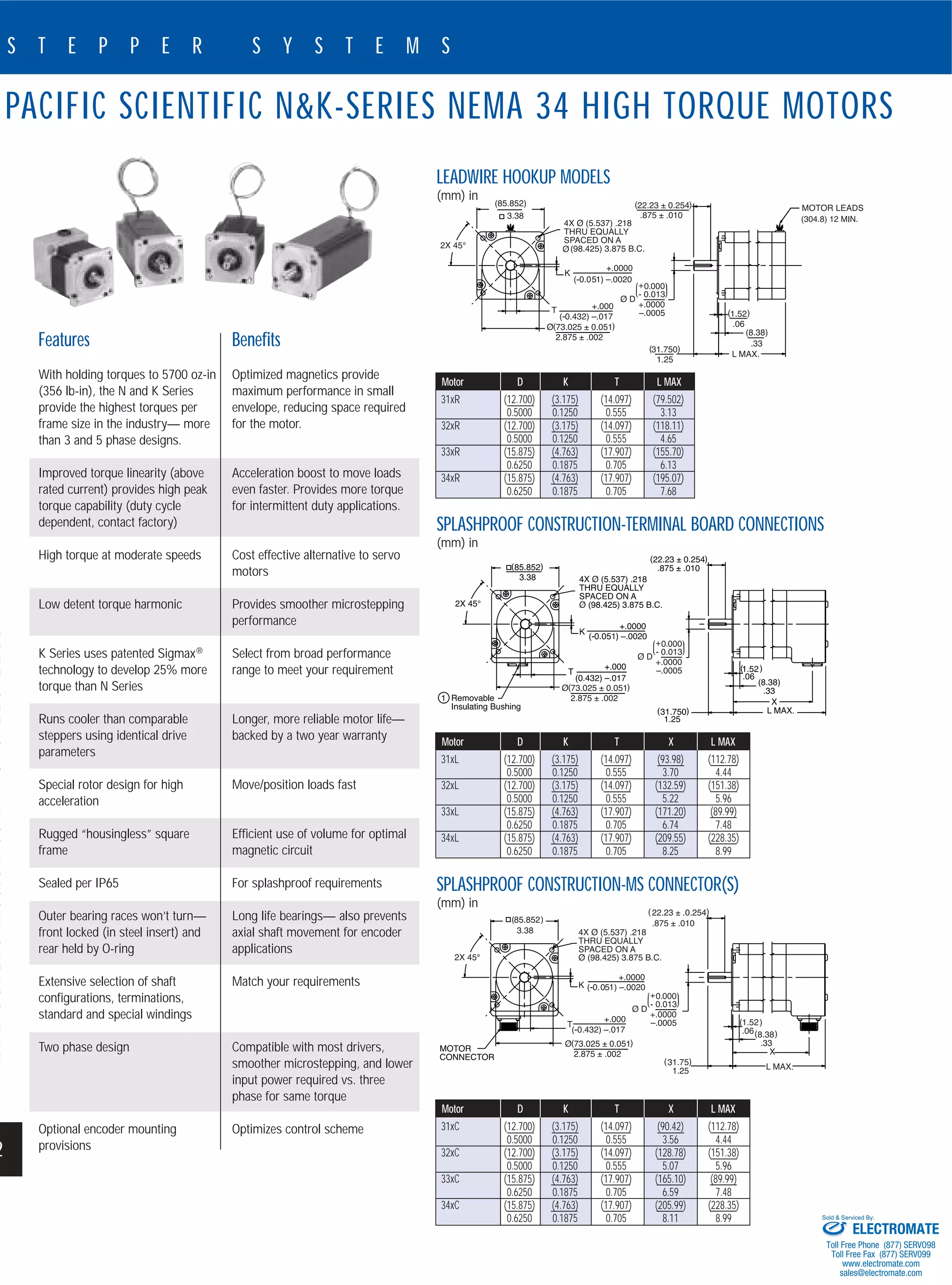

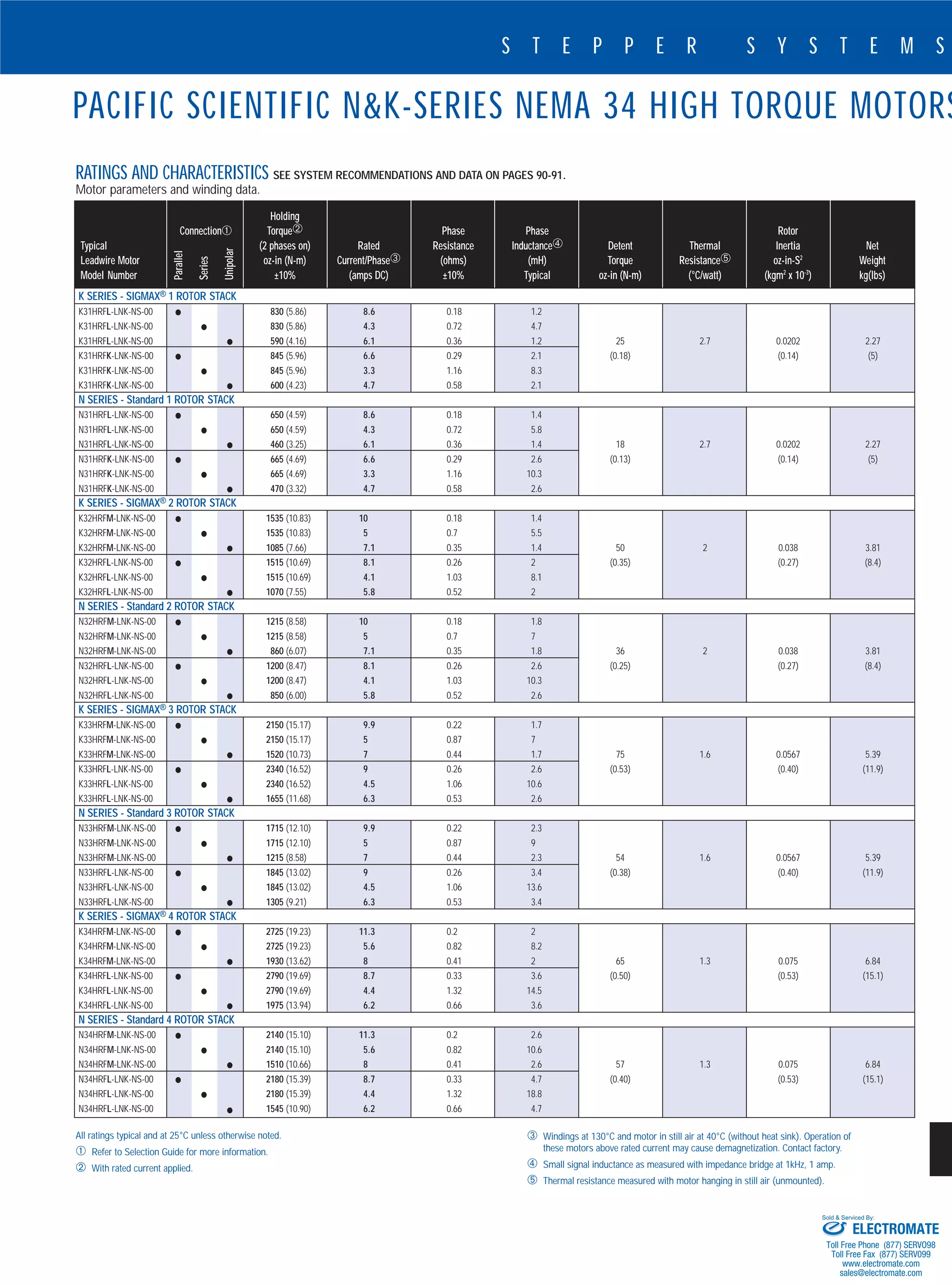

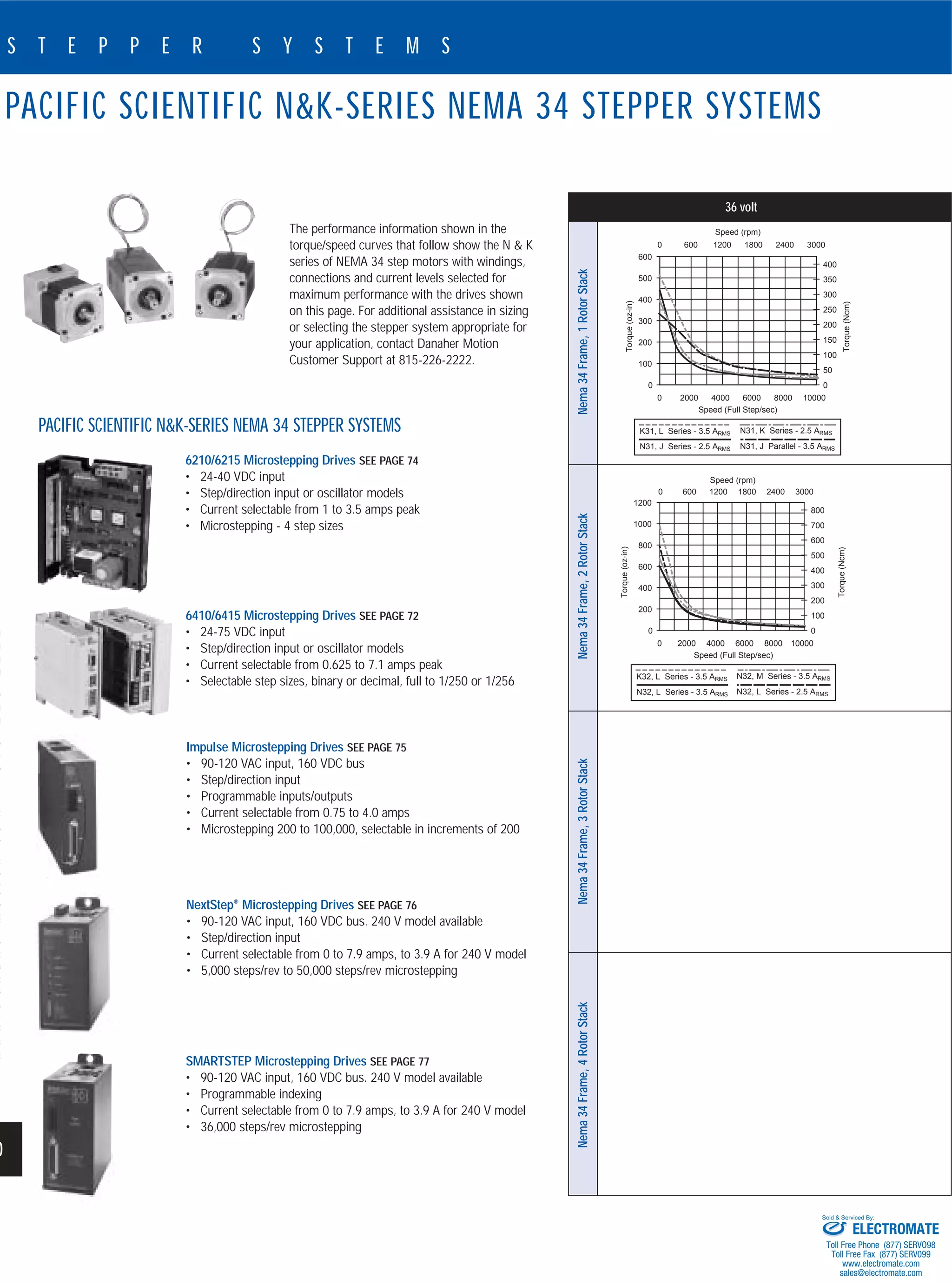

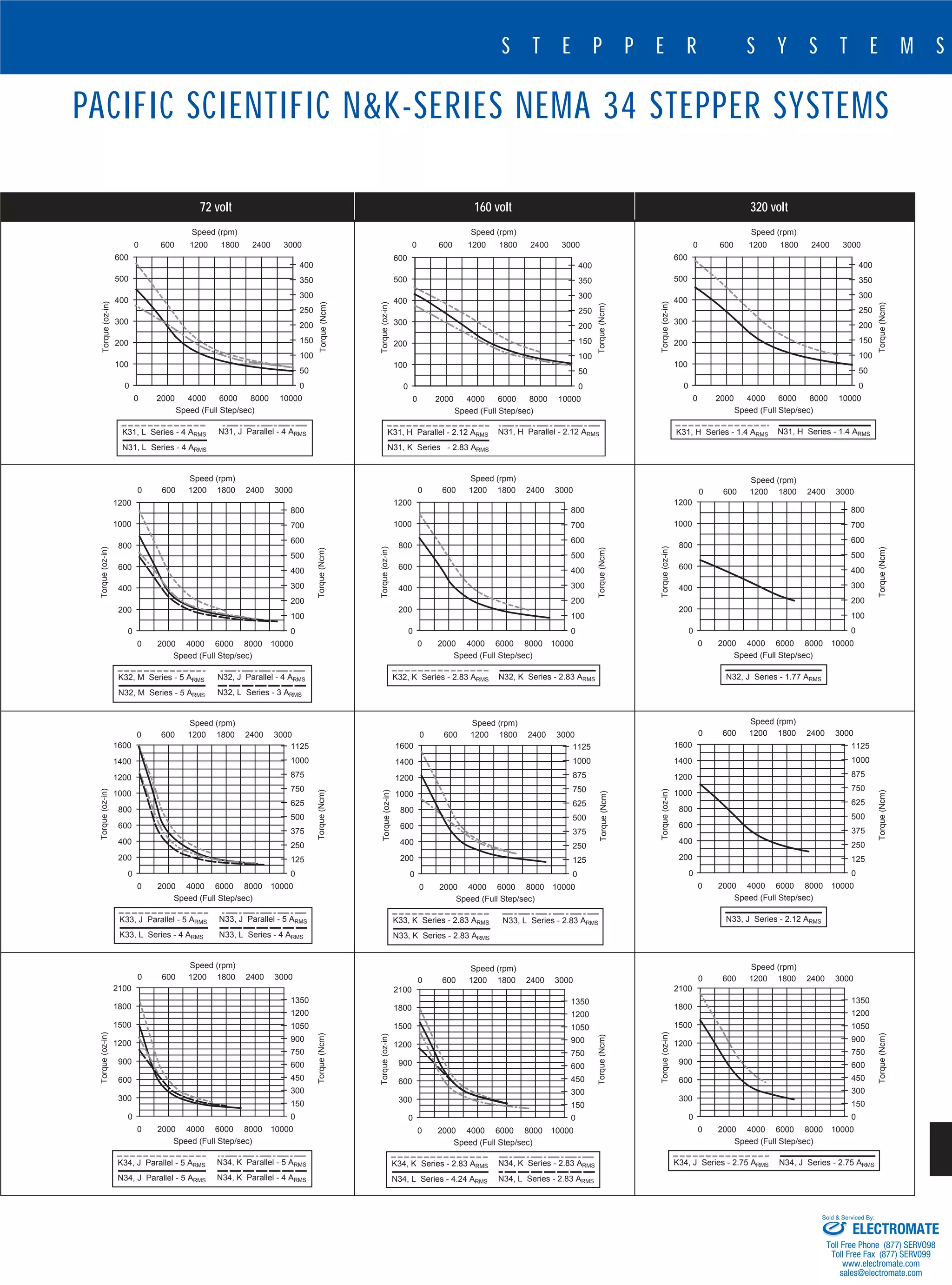

The document provides specifications for Pacific Scientific N&K-Series NEMA 34 high torque motors, including torque, current, resistance, inductance, detent torque, thermal resistance, and inertia ratings for various motor models. It also lists features and benefits of the motor series such as high torque capability, improved torque linearity, rugged construction, and optional encoder mounting provisions.