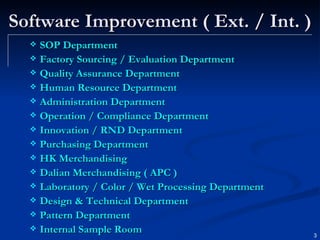

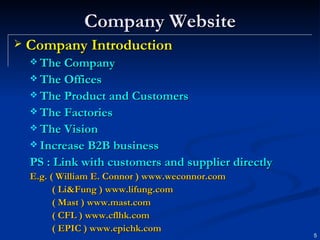

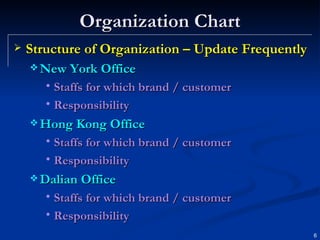

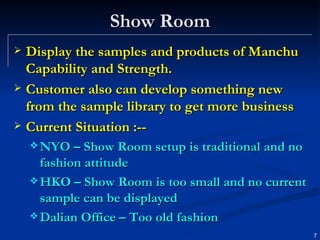

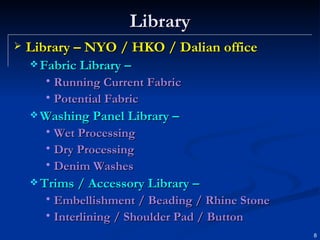

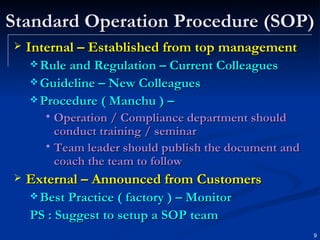

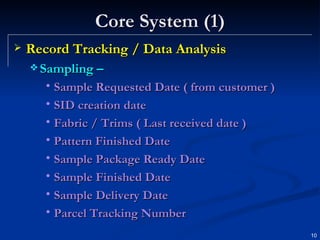

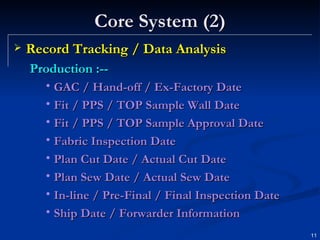

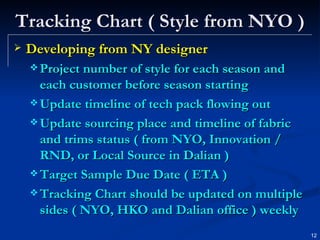

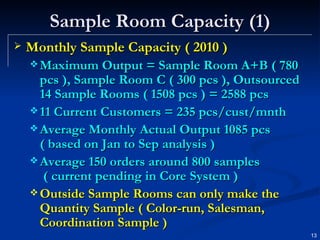

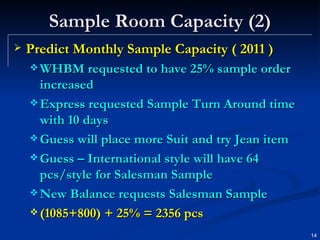

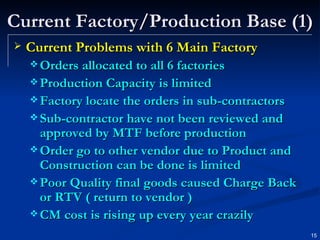

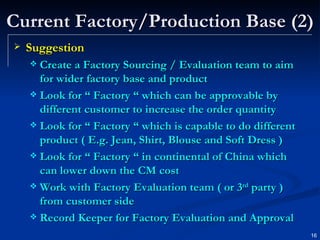

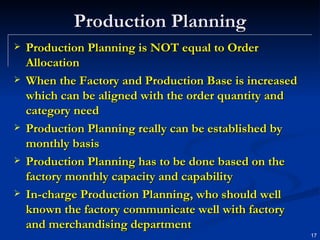

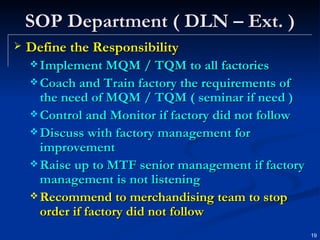

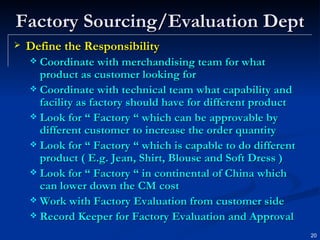

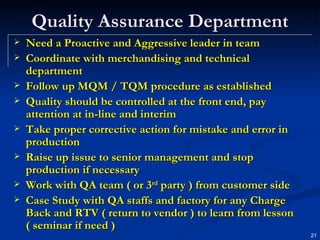

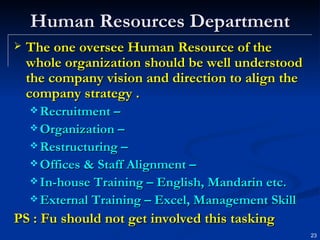

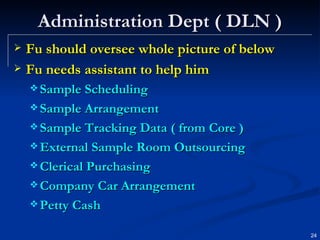

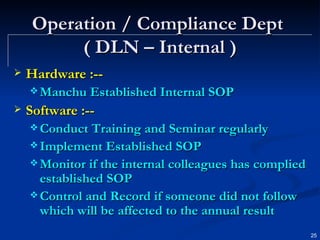

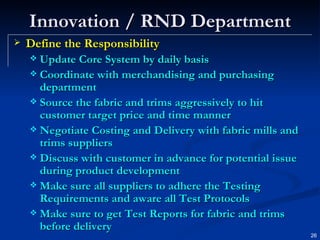

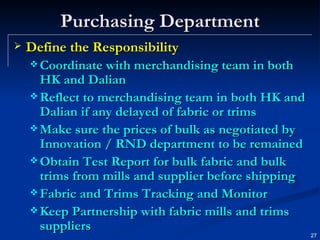

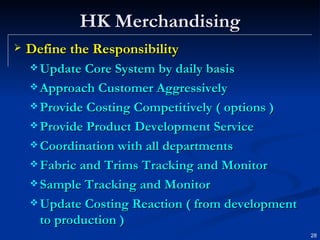

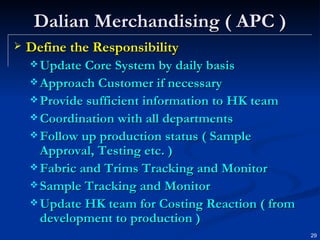

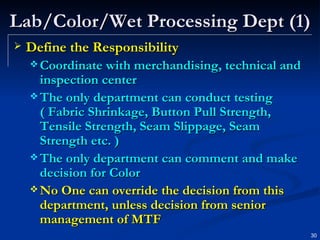

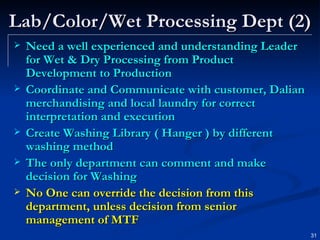

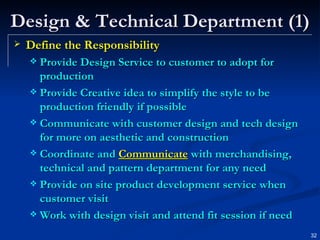

The document proposes hardware and software improvements for Manchu Times Fashion. It recommends updating the company website, showroom, sample library, and standard operating procedures. It suggests improving the organization chart, sample room capacity, and production planning across offices in New York, Hong Kong, and Dalian. It also proposes enhancing core tracking systems and departments like sourcing, quality assurance, and innovation to better serve customers.