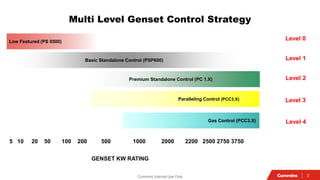

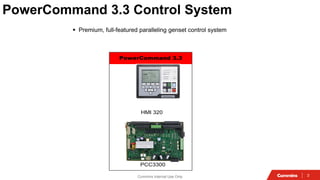

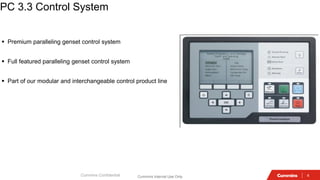

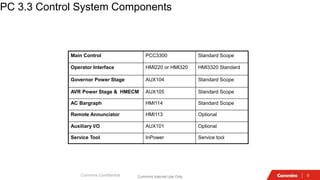

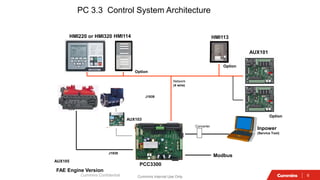

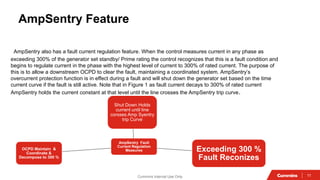

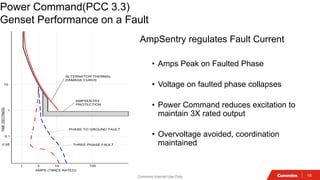

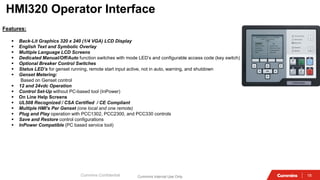

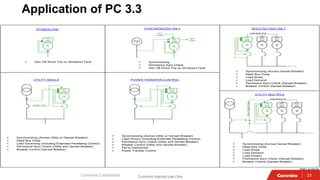

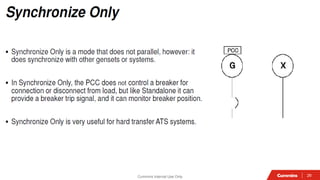

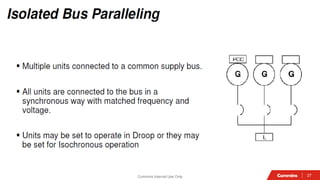

The document discusses Cummins PowerCommand 3.3 genset control system. It is a premium paralleling control system that provides full-featured control for standalone and paralleling genset applications. The system includes the PCC3300 controller, HMI operator interfaces, auxiliary I/O modules, and InPower service tool software. It offers features like digital voltage regulation, electronic governing, engine monitoring, AC alternator protection, data logging, and paralleling controls. The document provides details on the control system components, architecture, features, accessories, and application types.