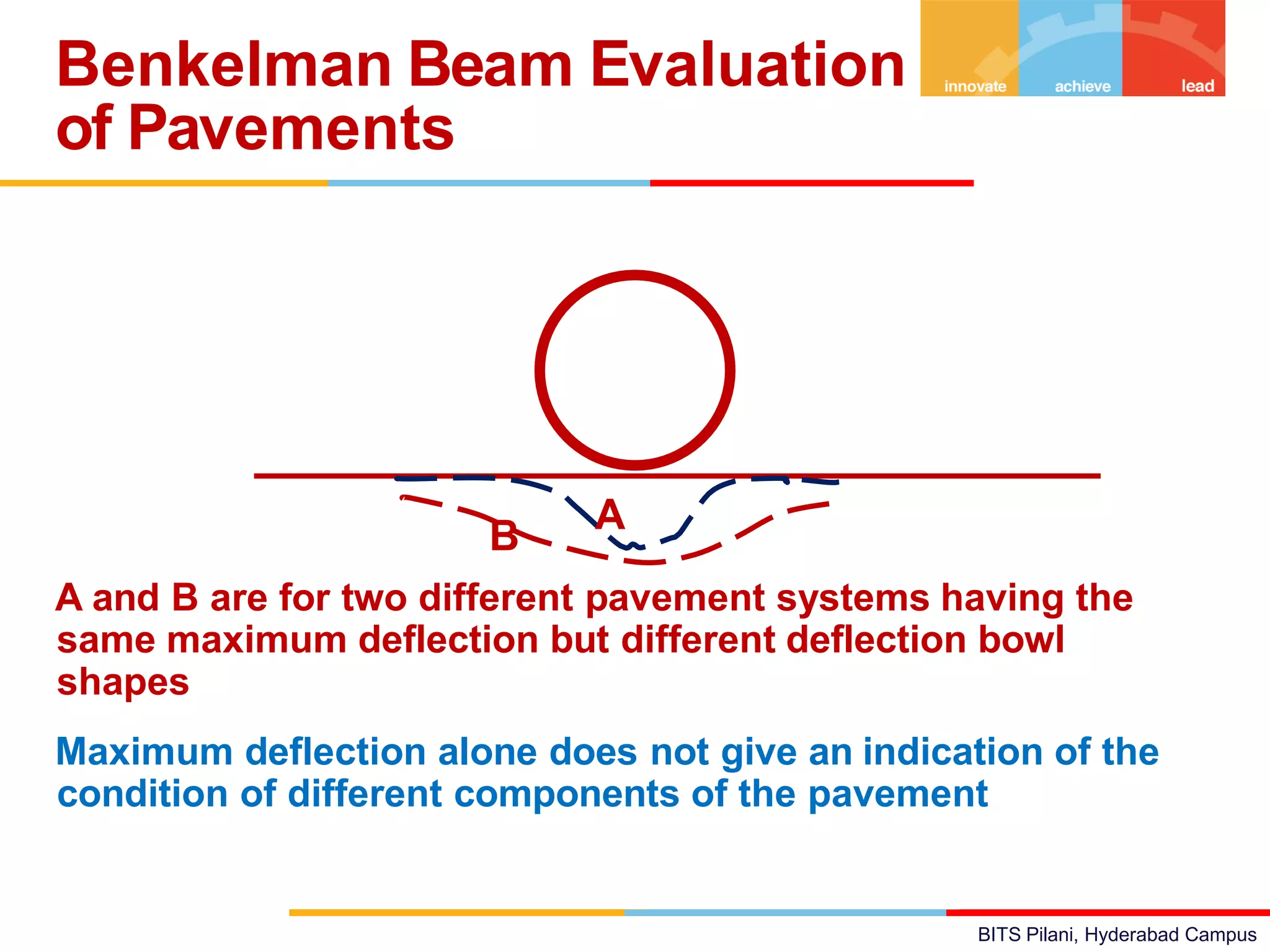

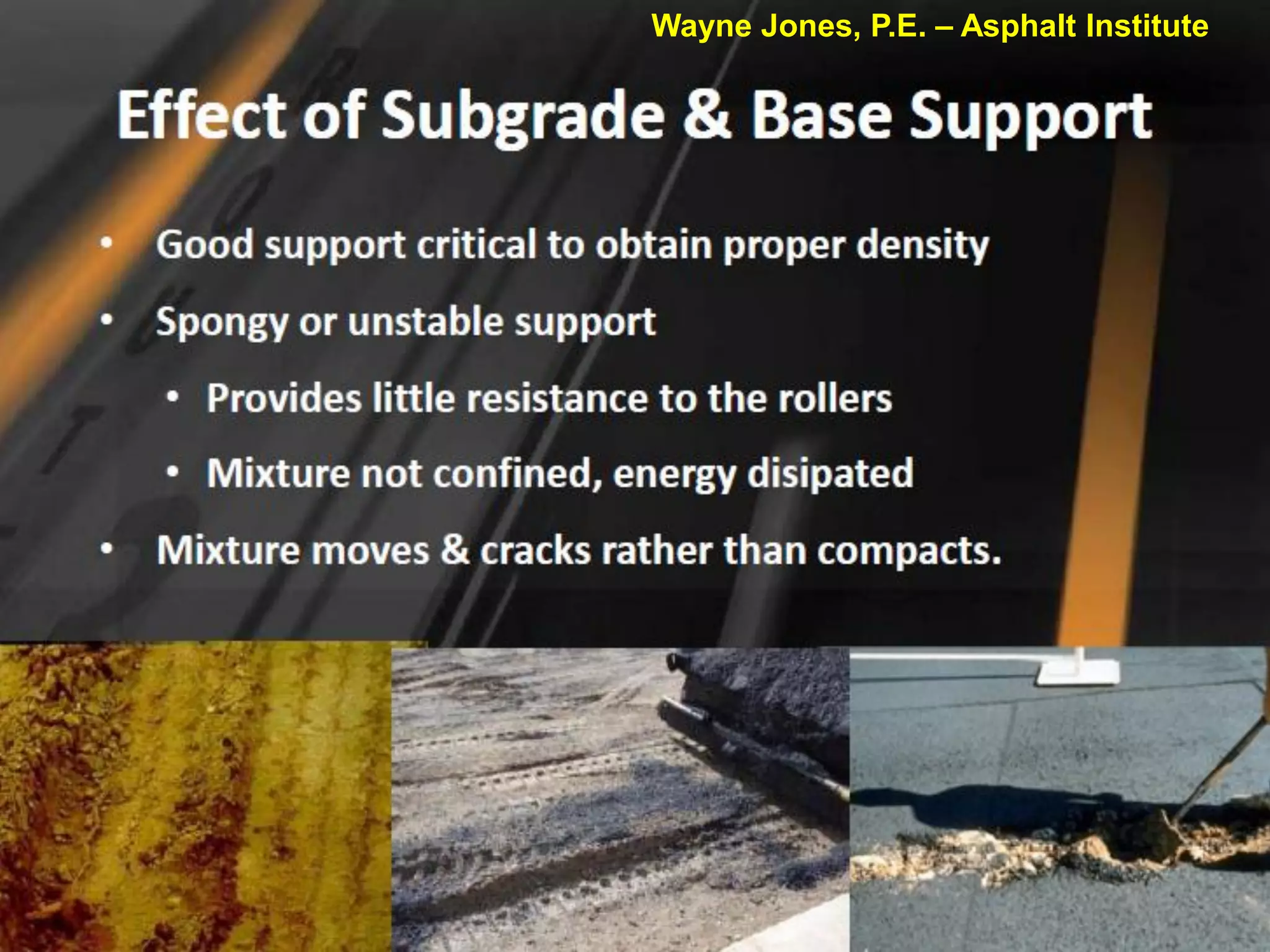

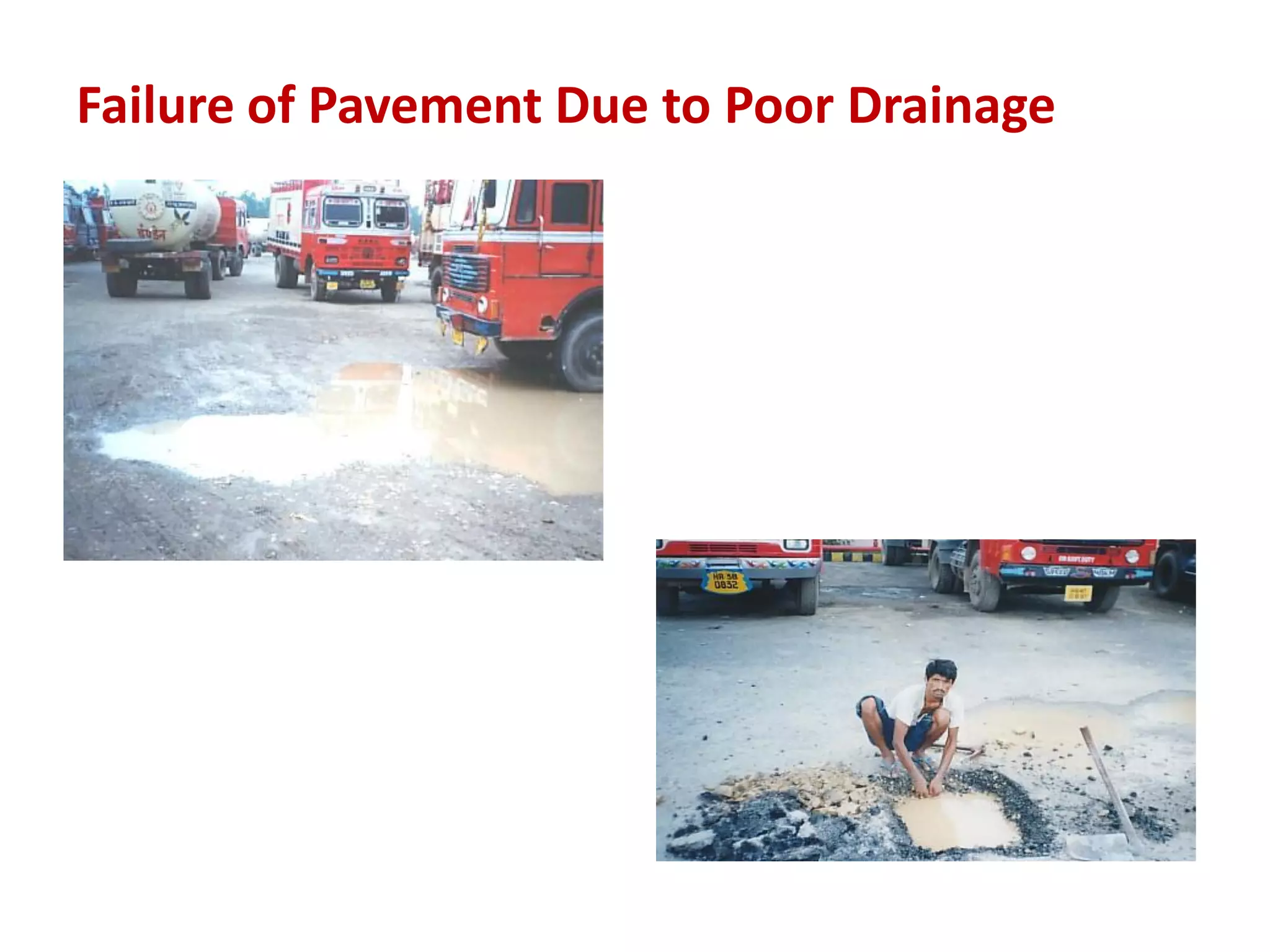

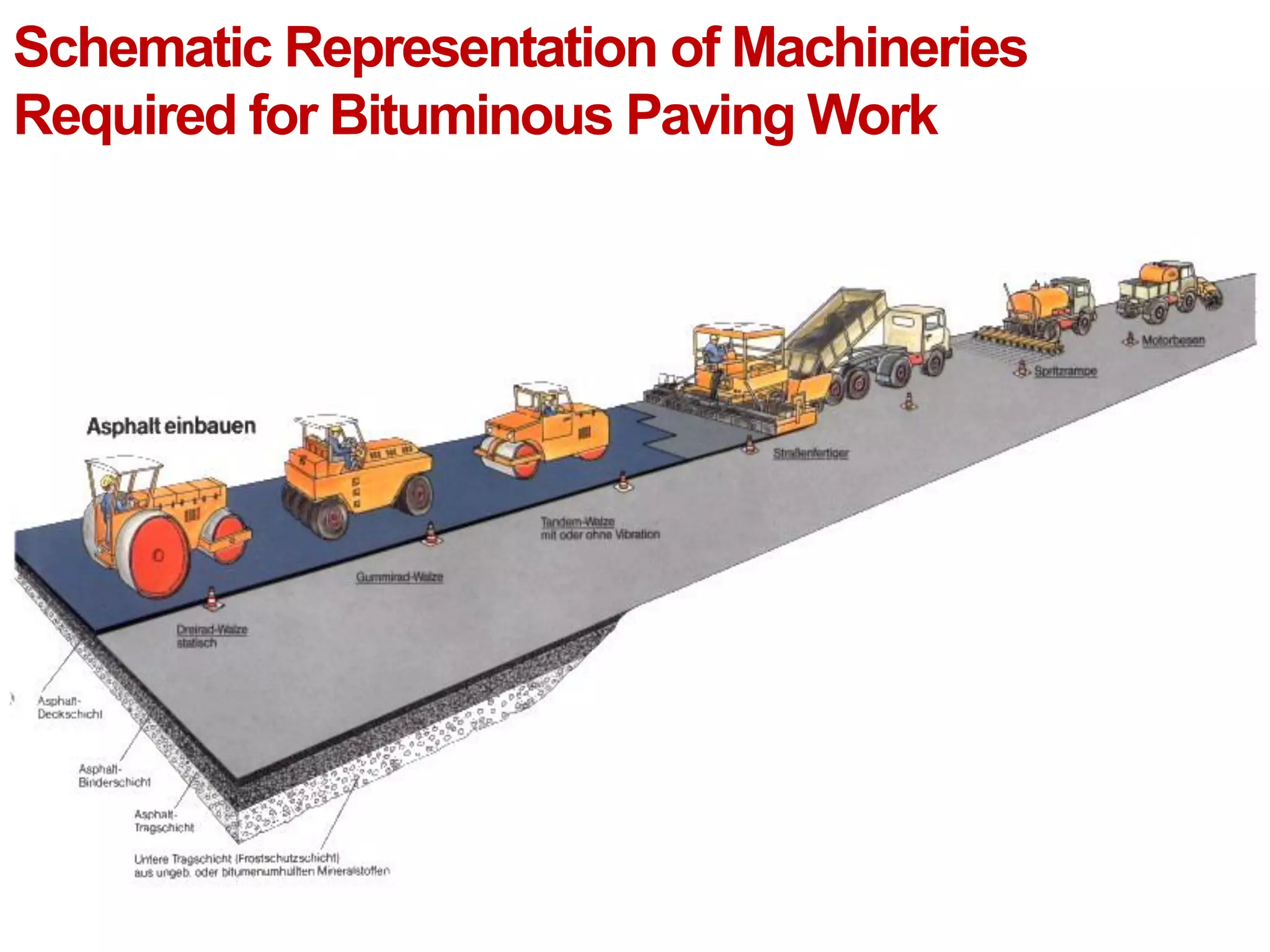

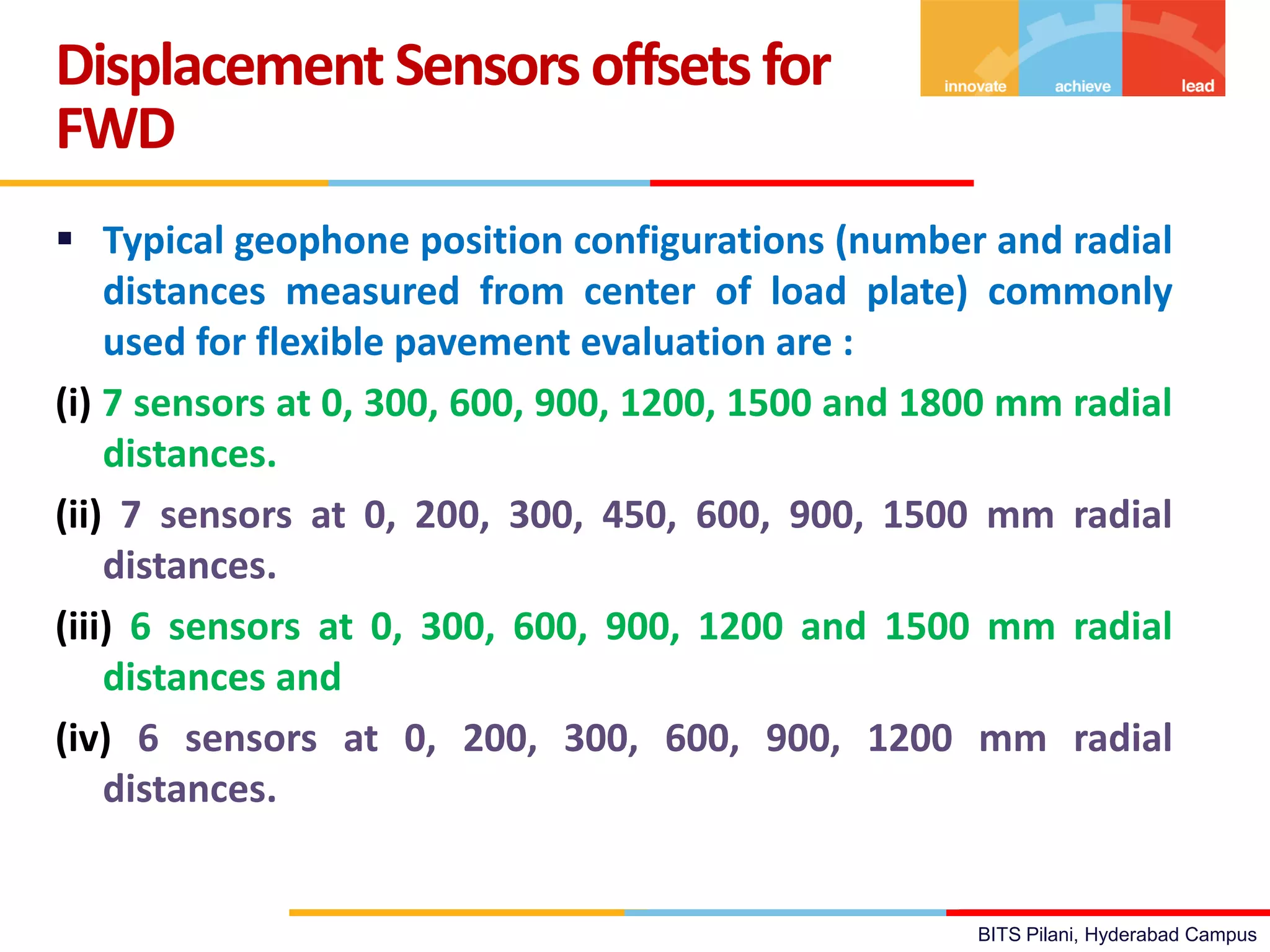

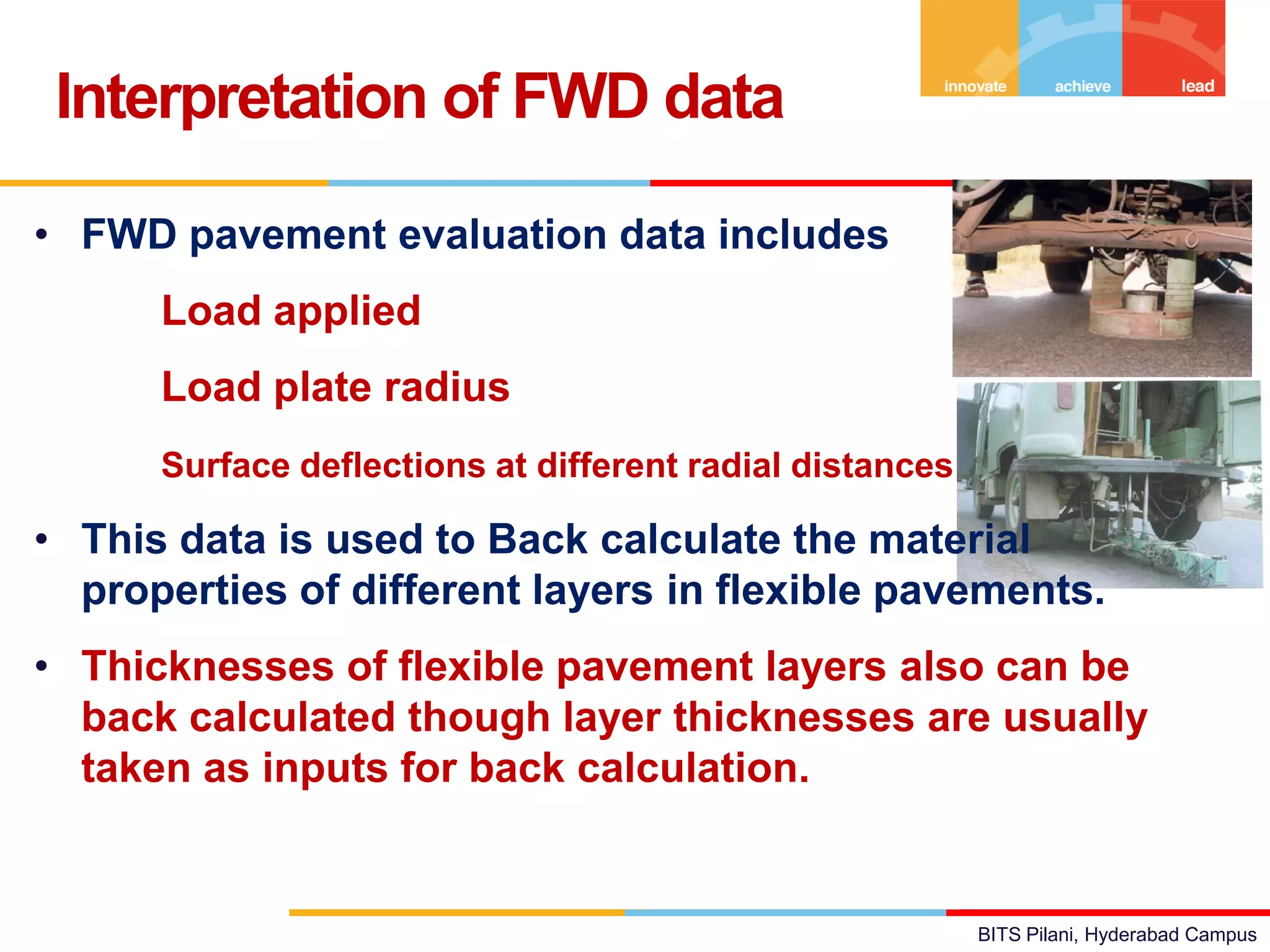

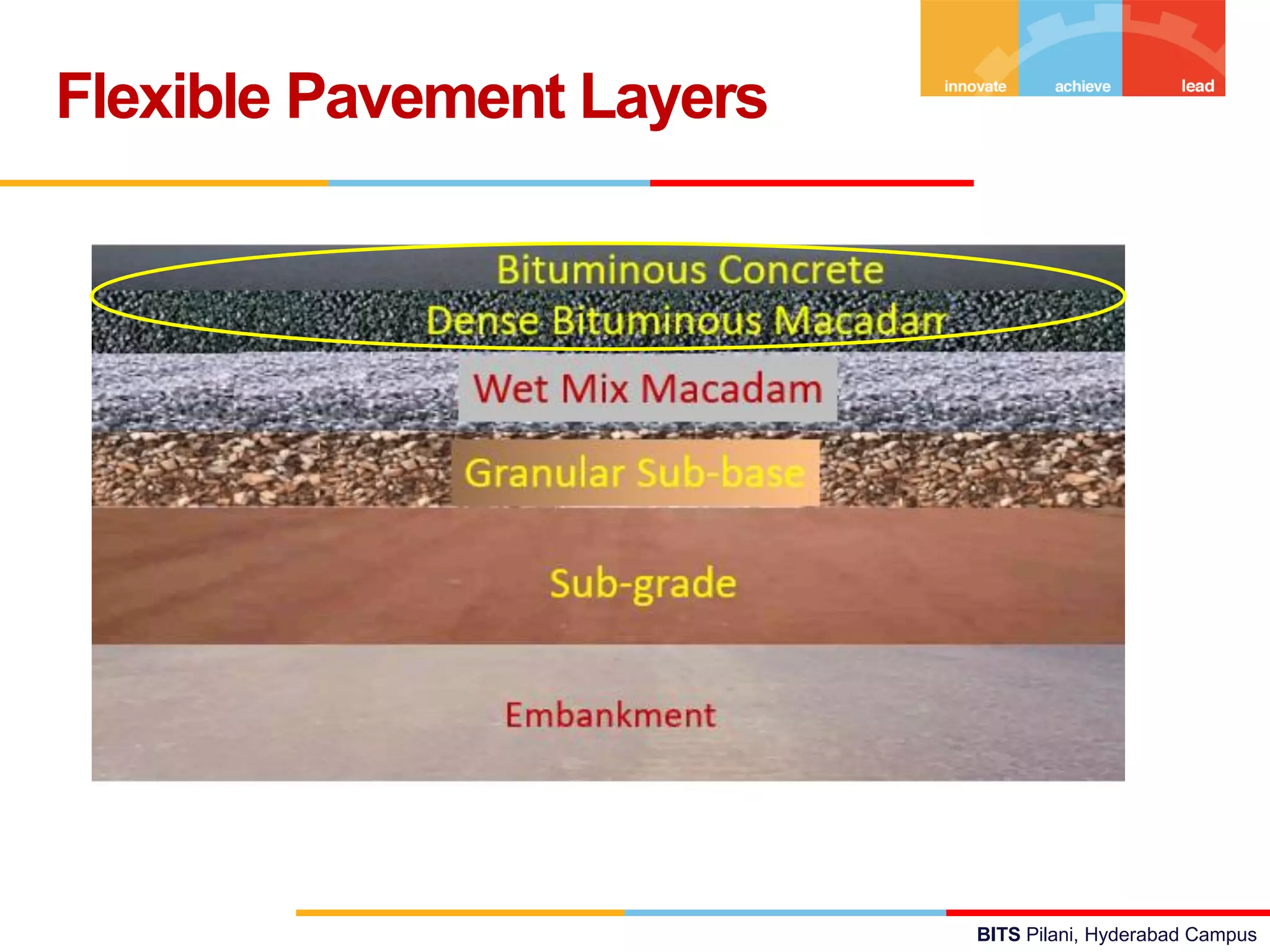

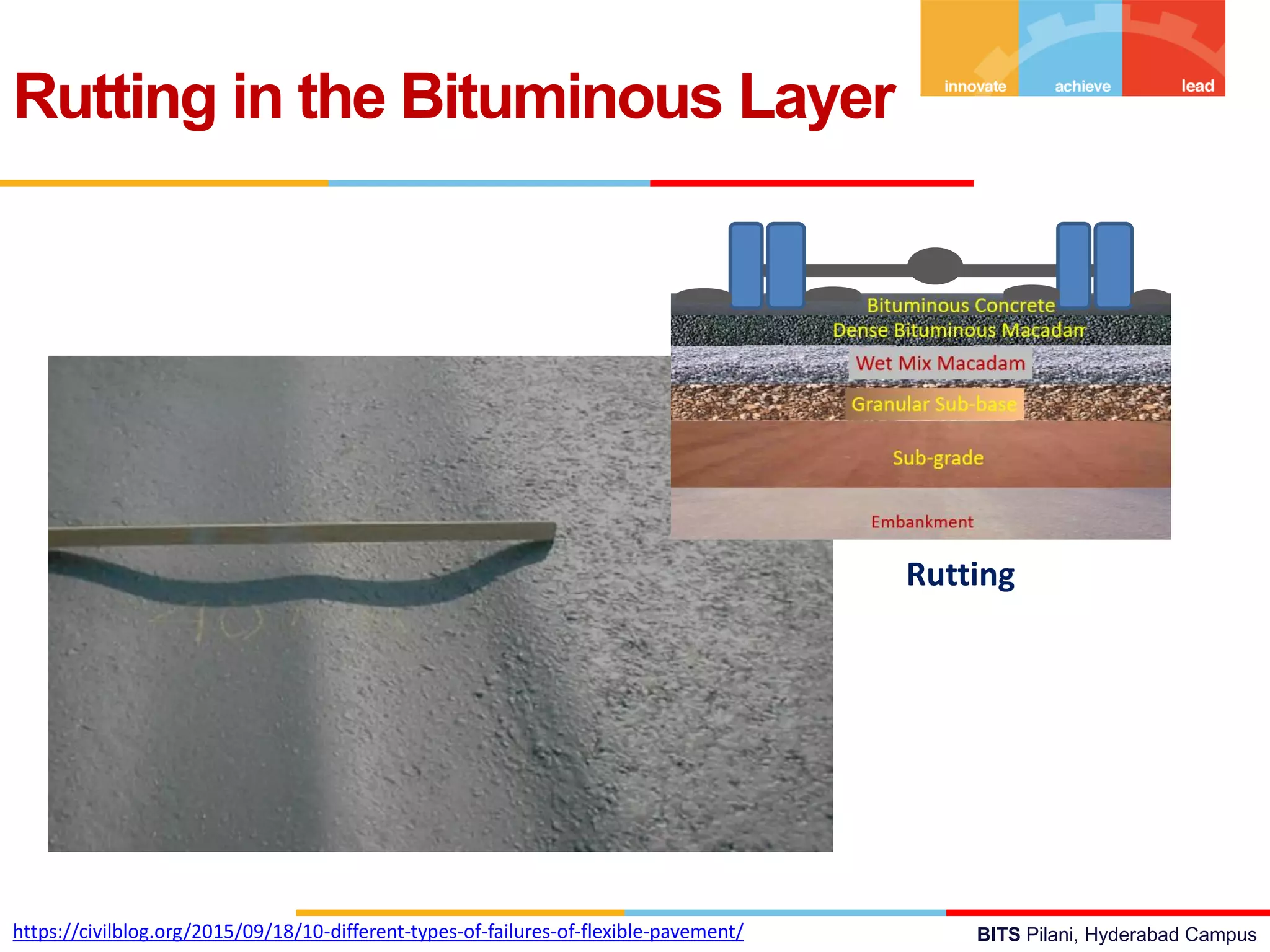

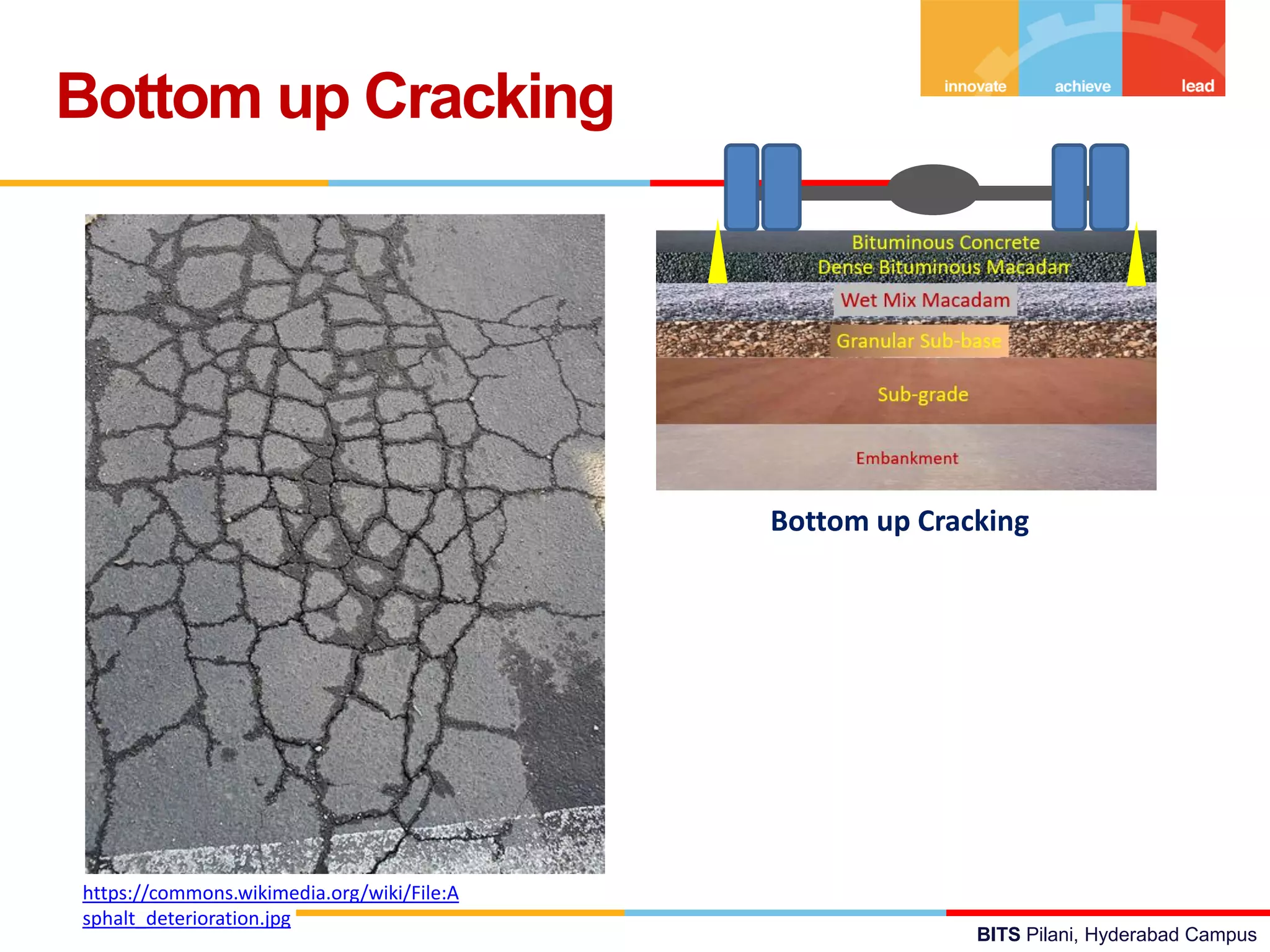

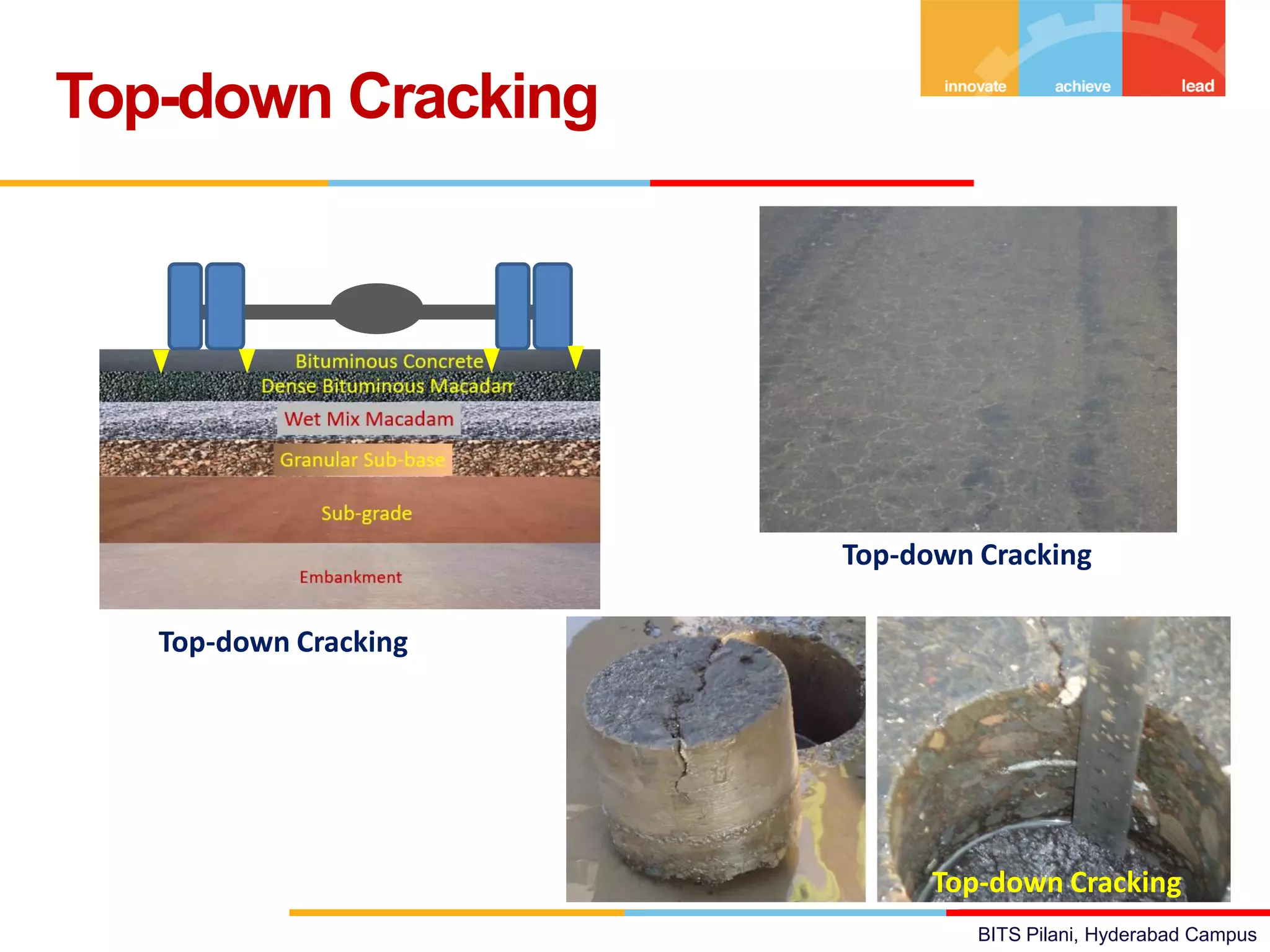

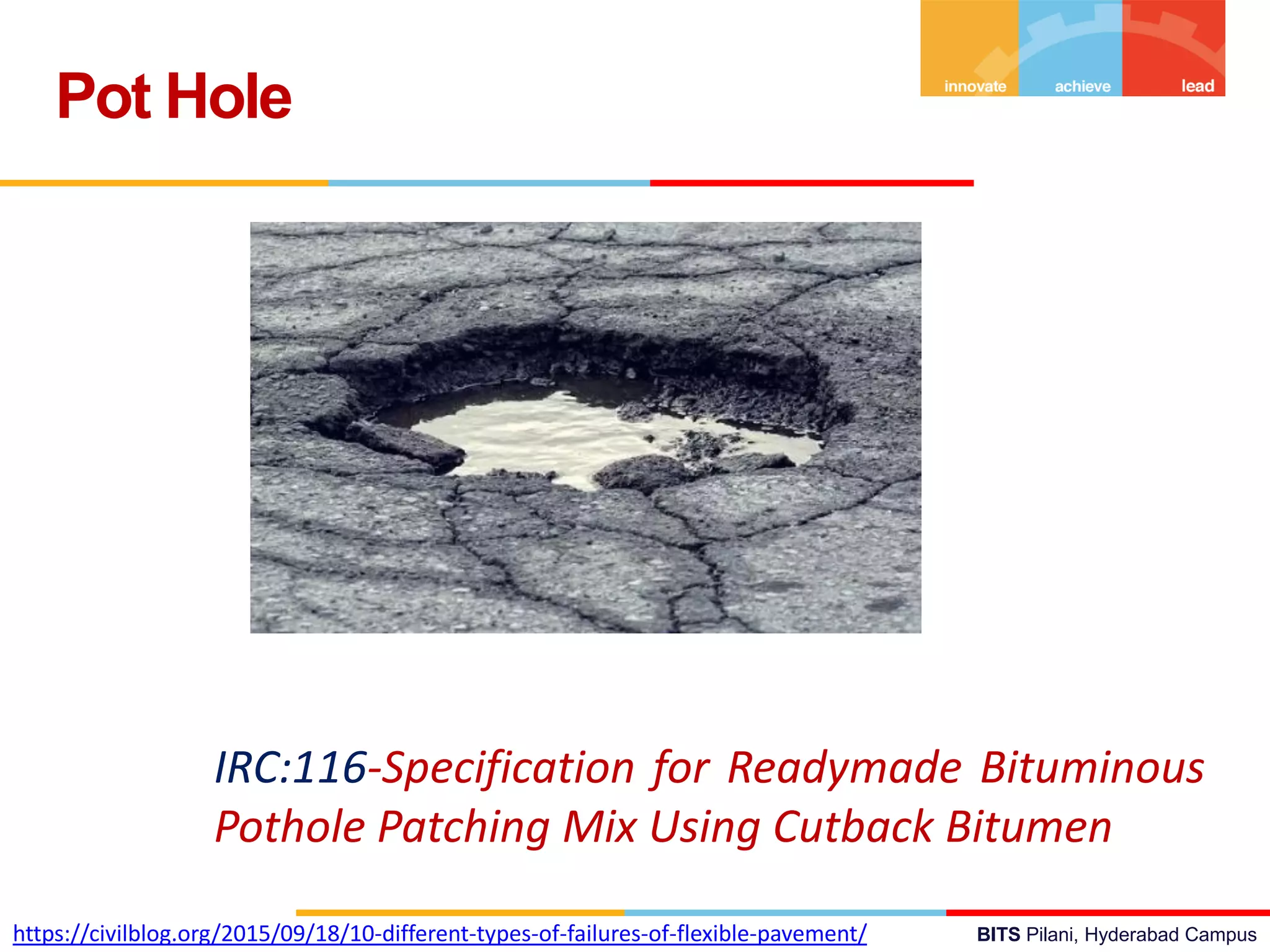

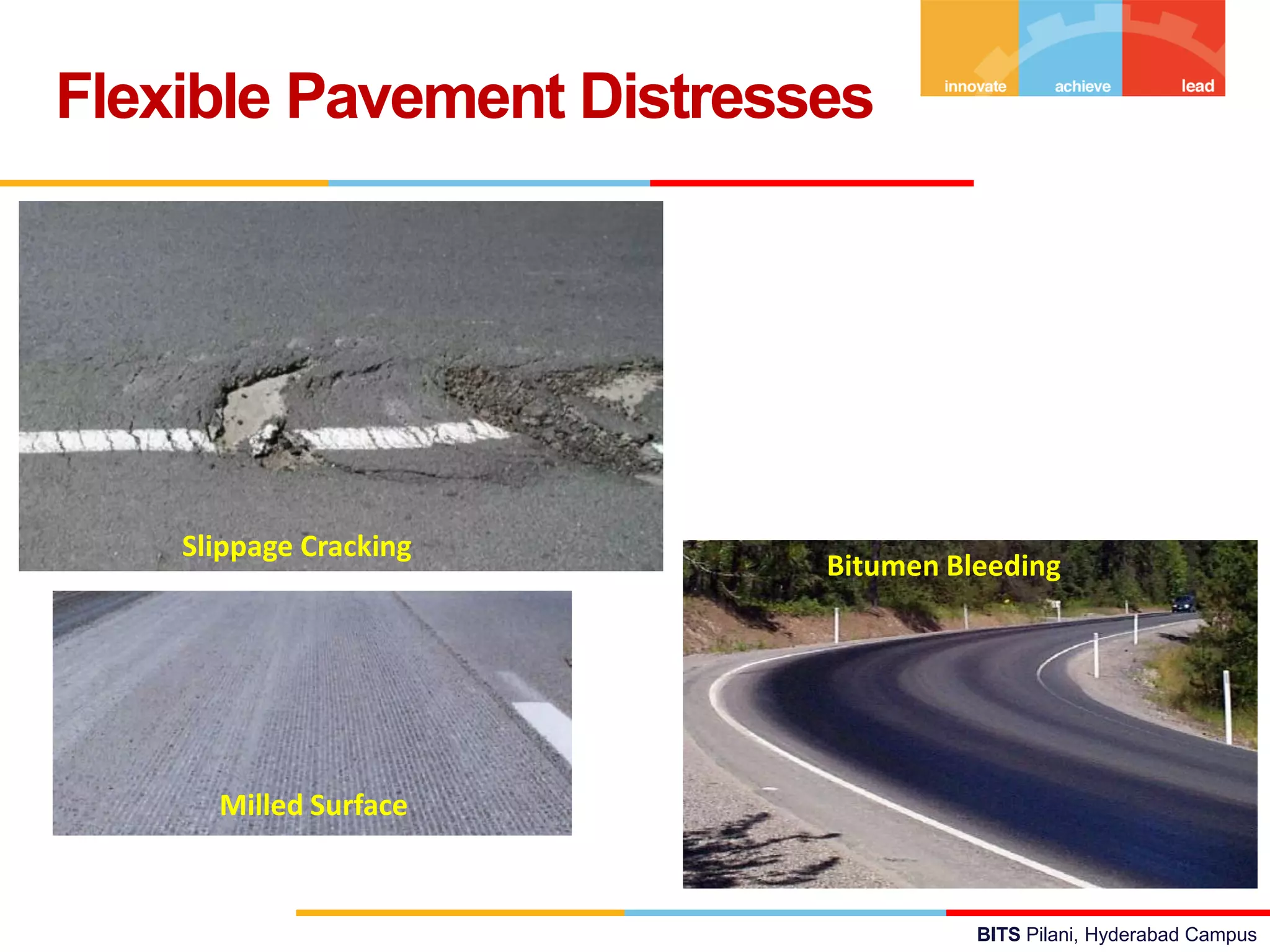

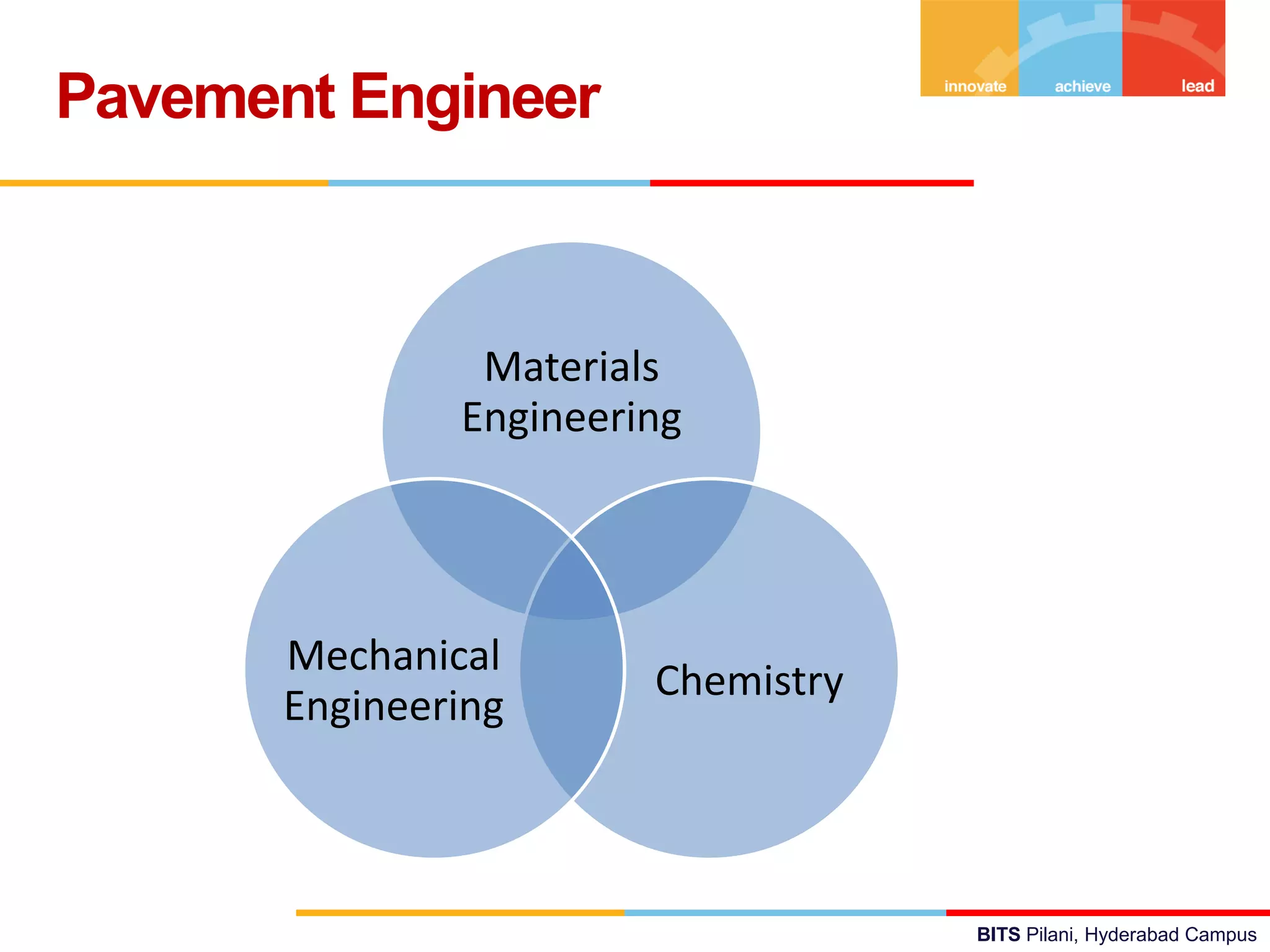

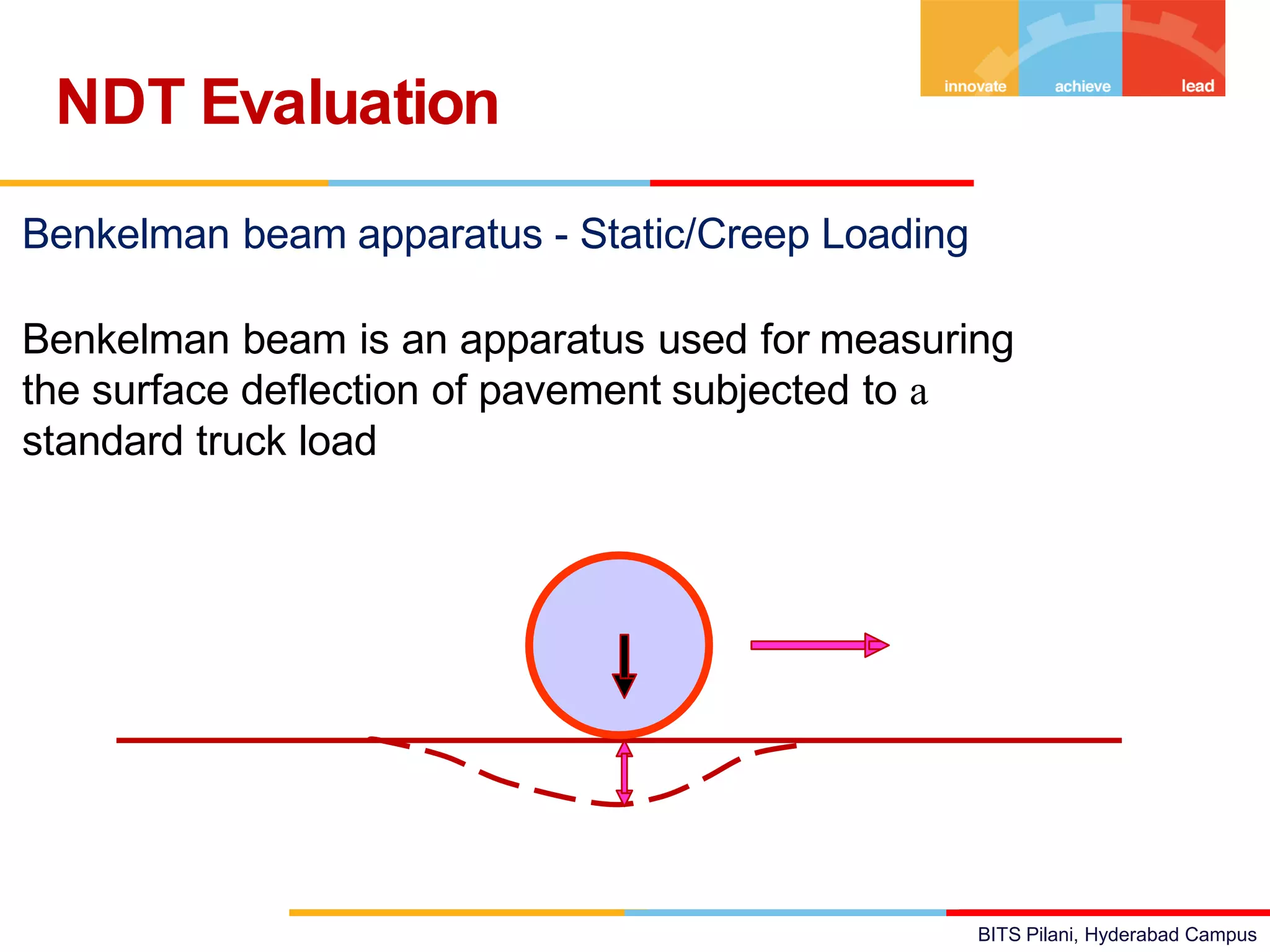

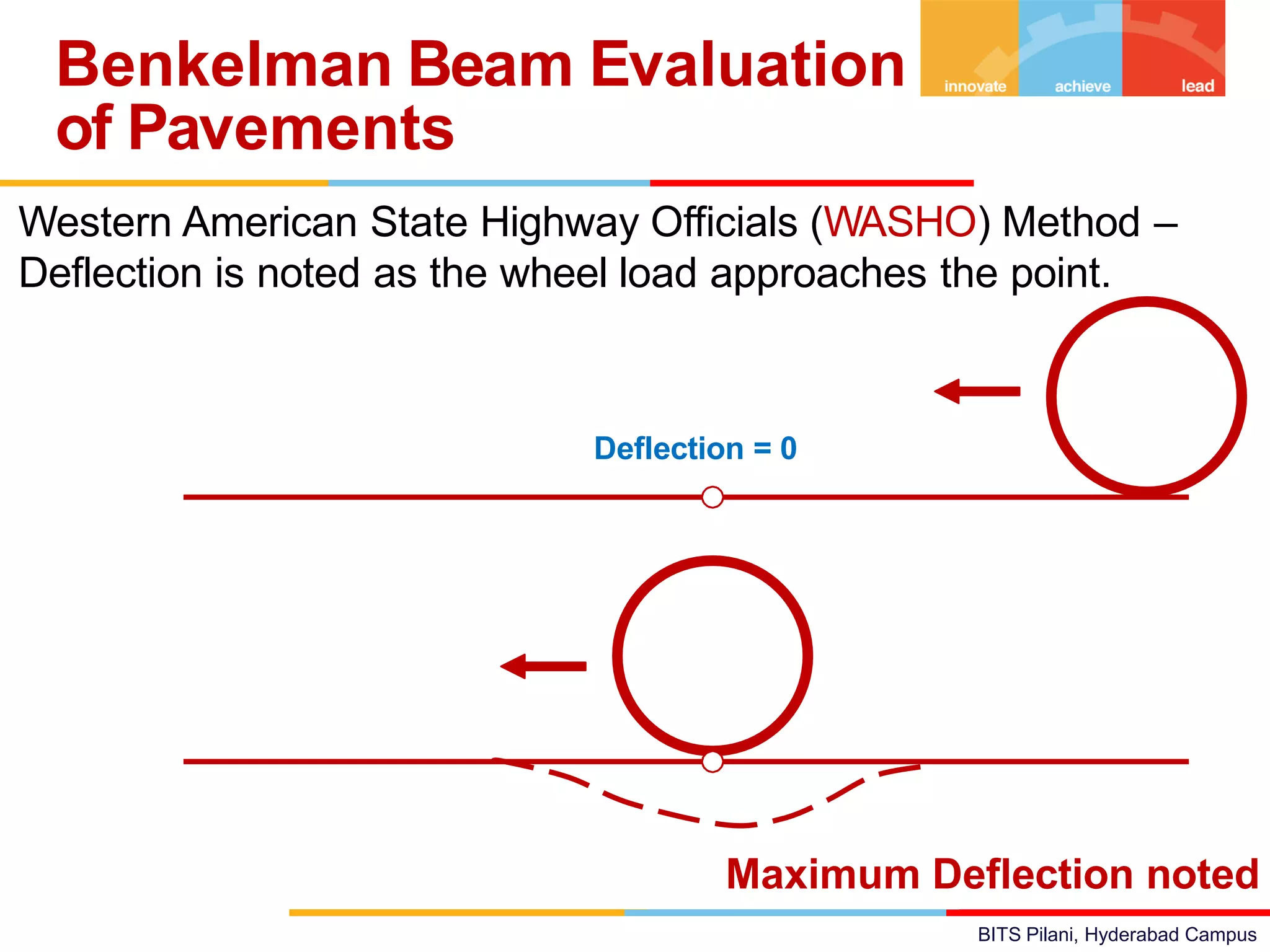

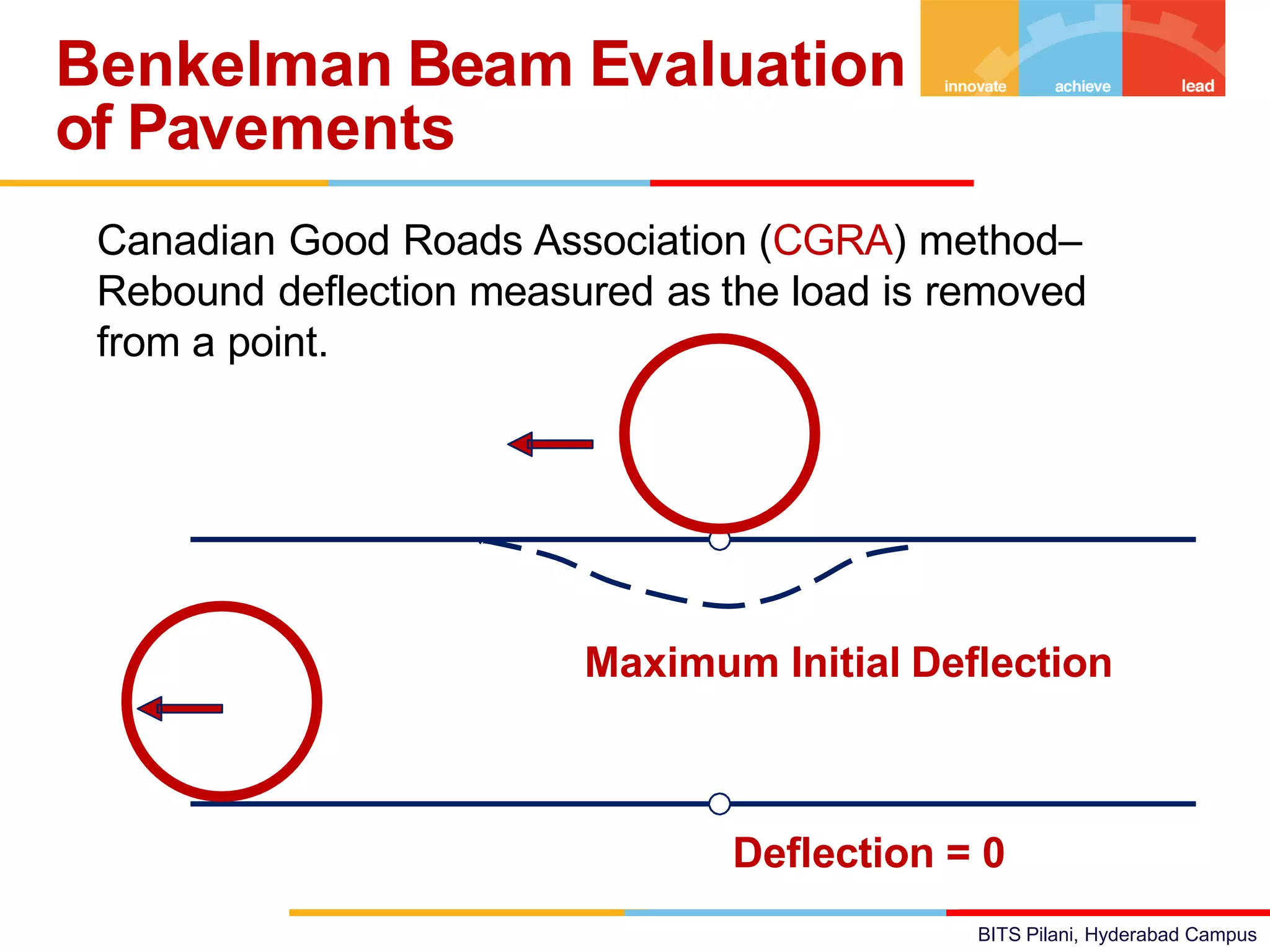

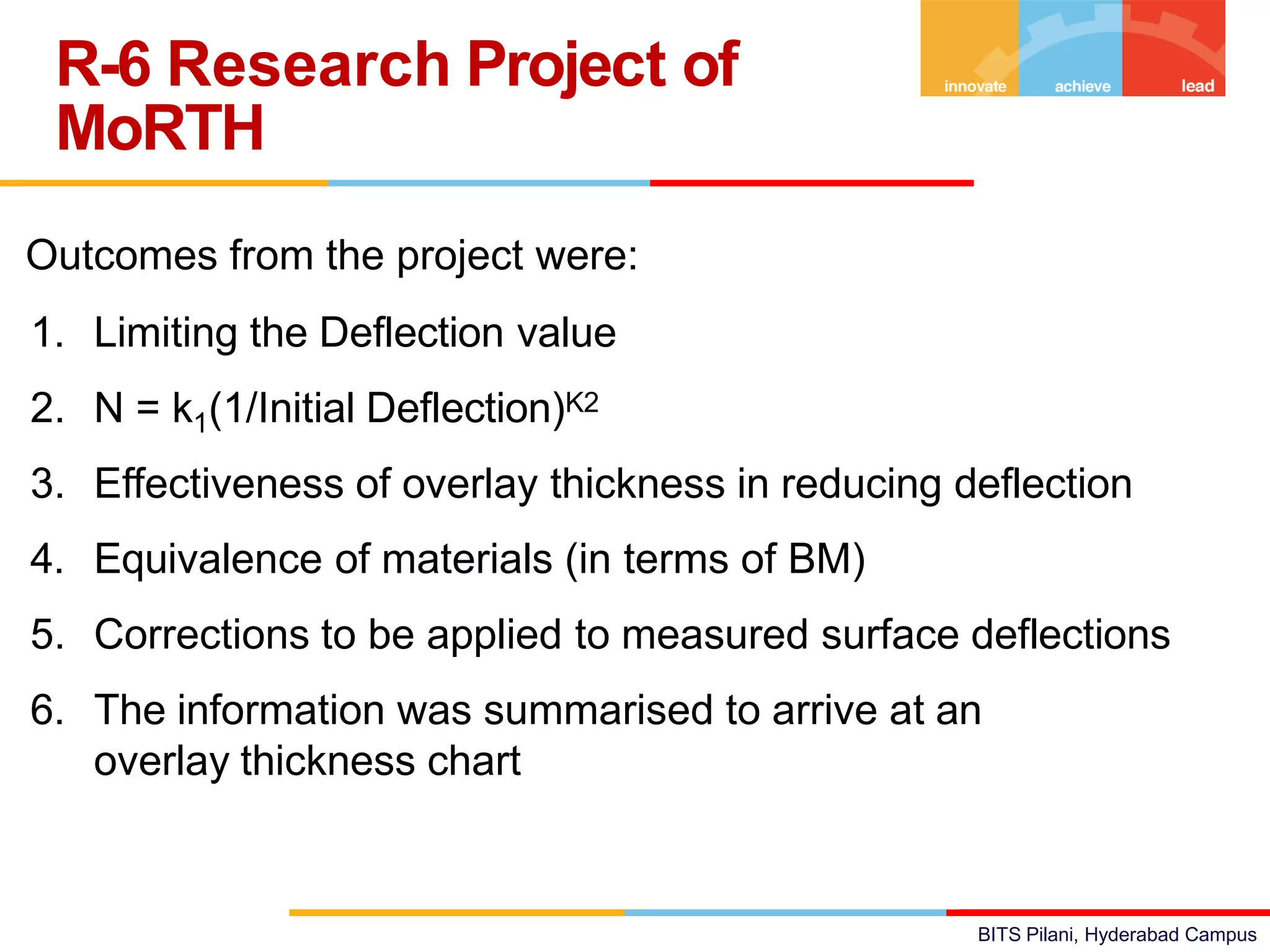

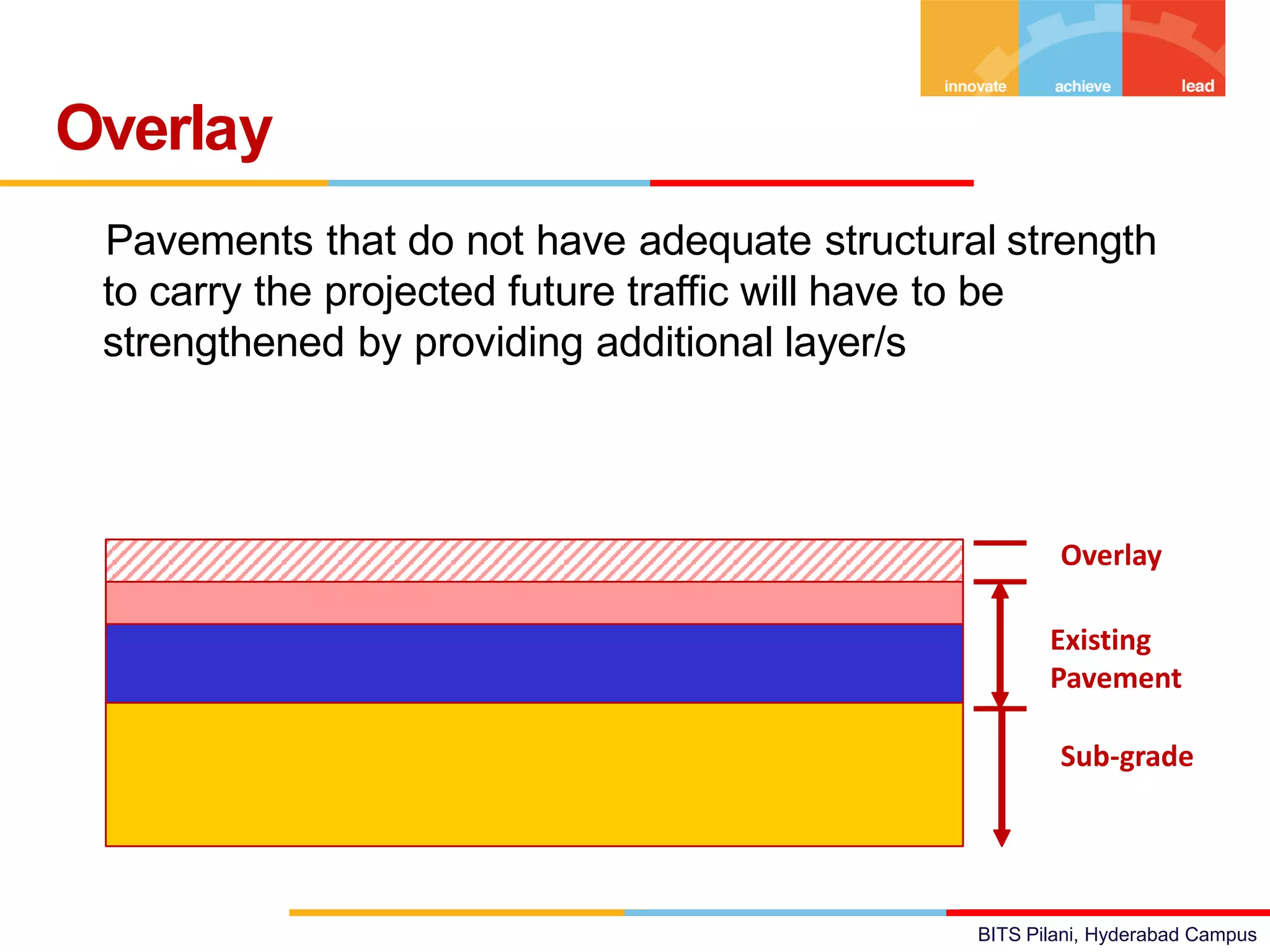

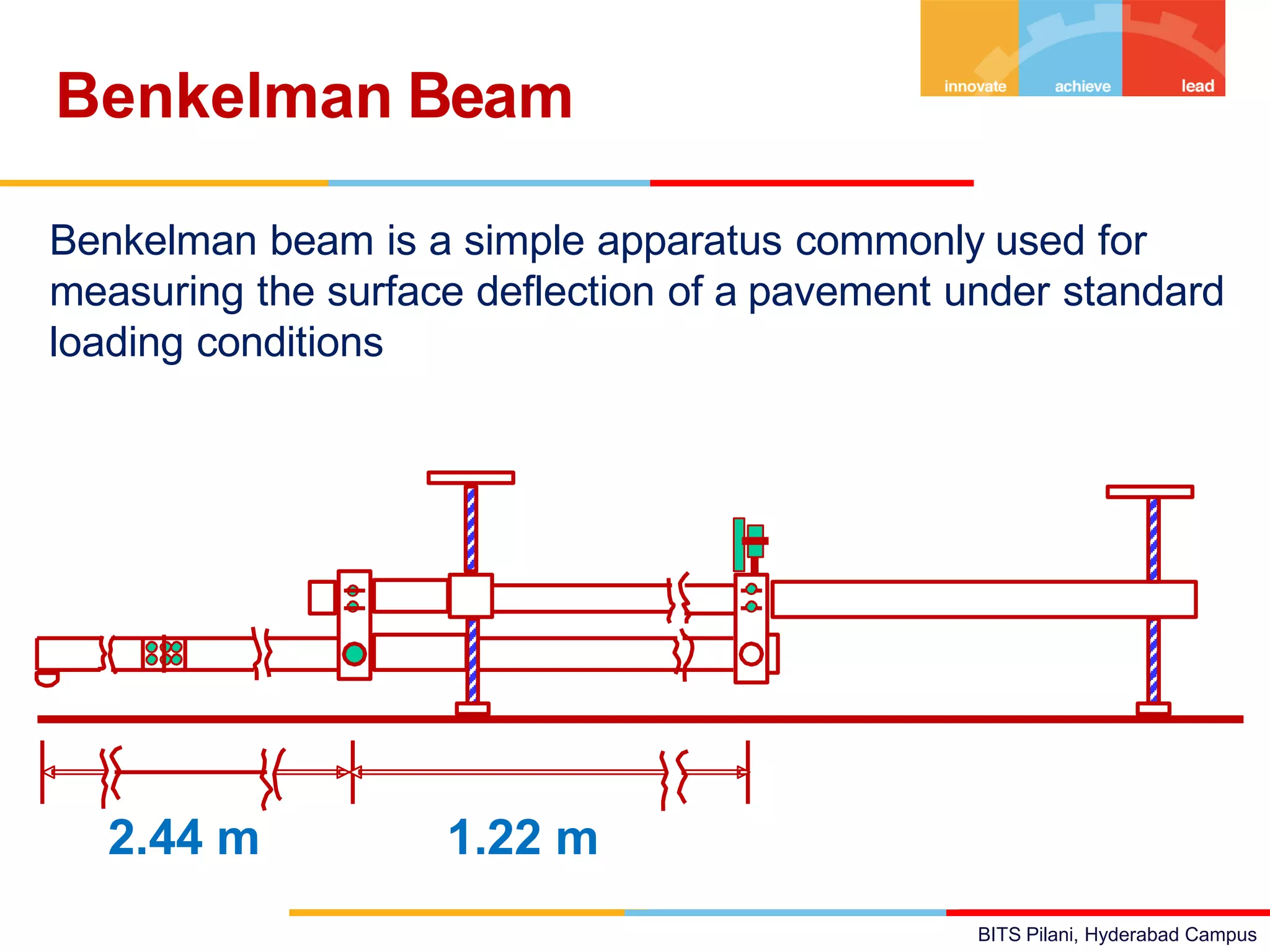

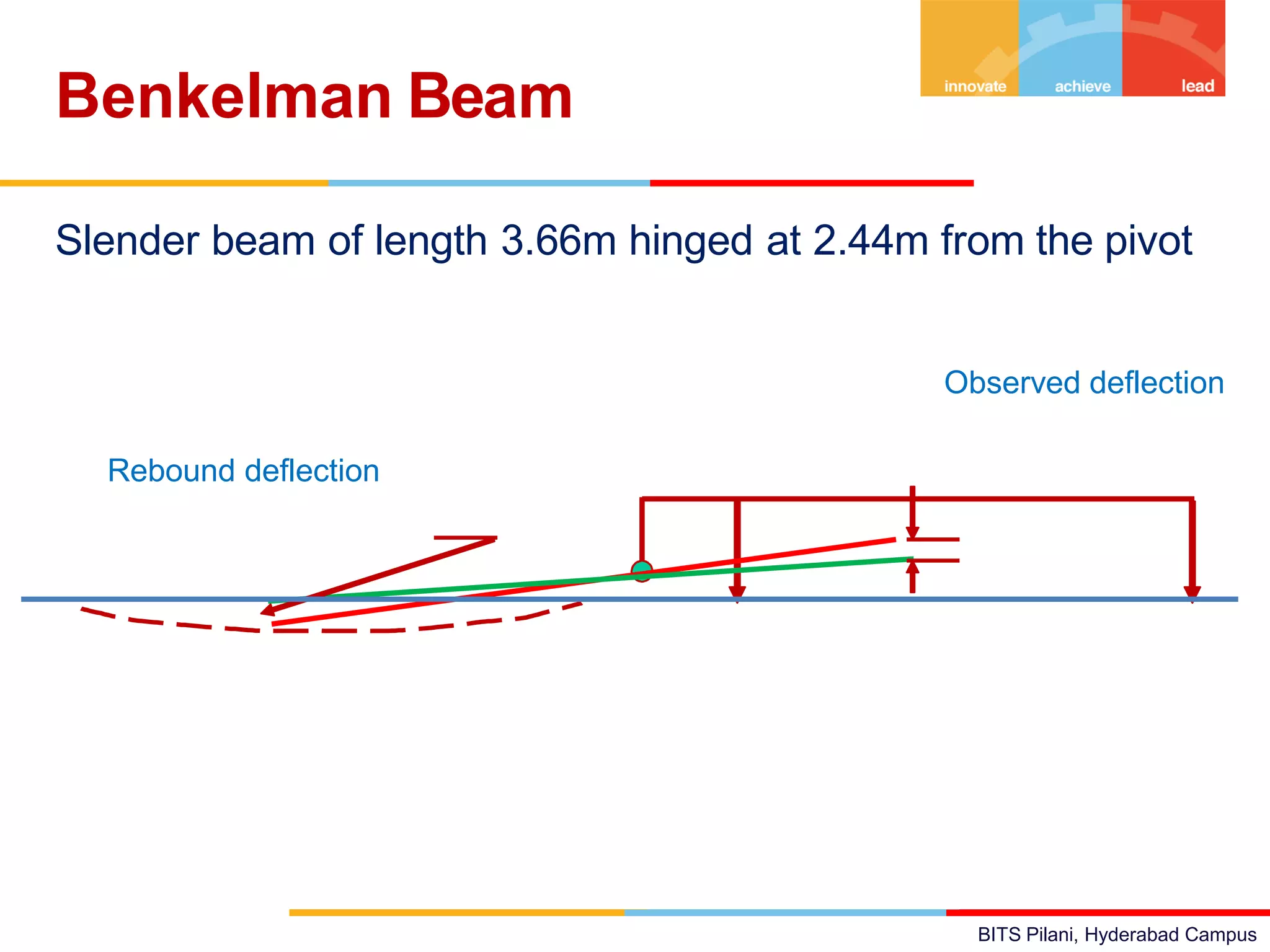

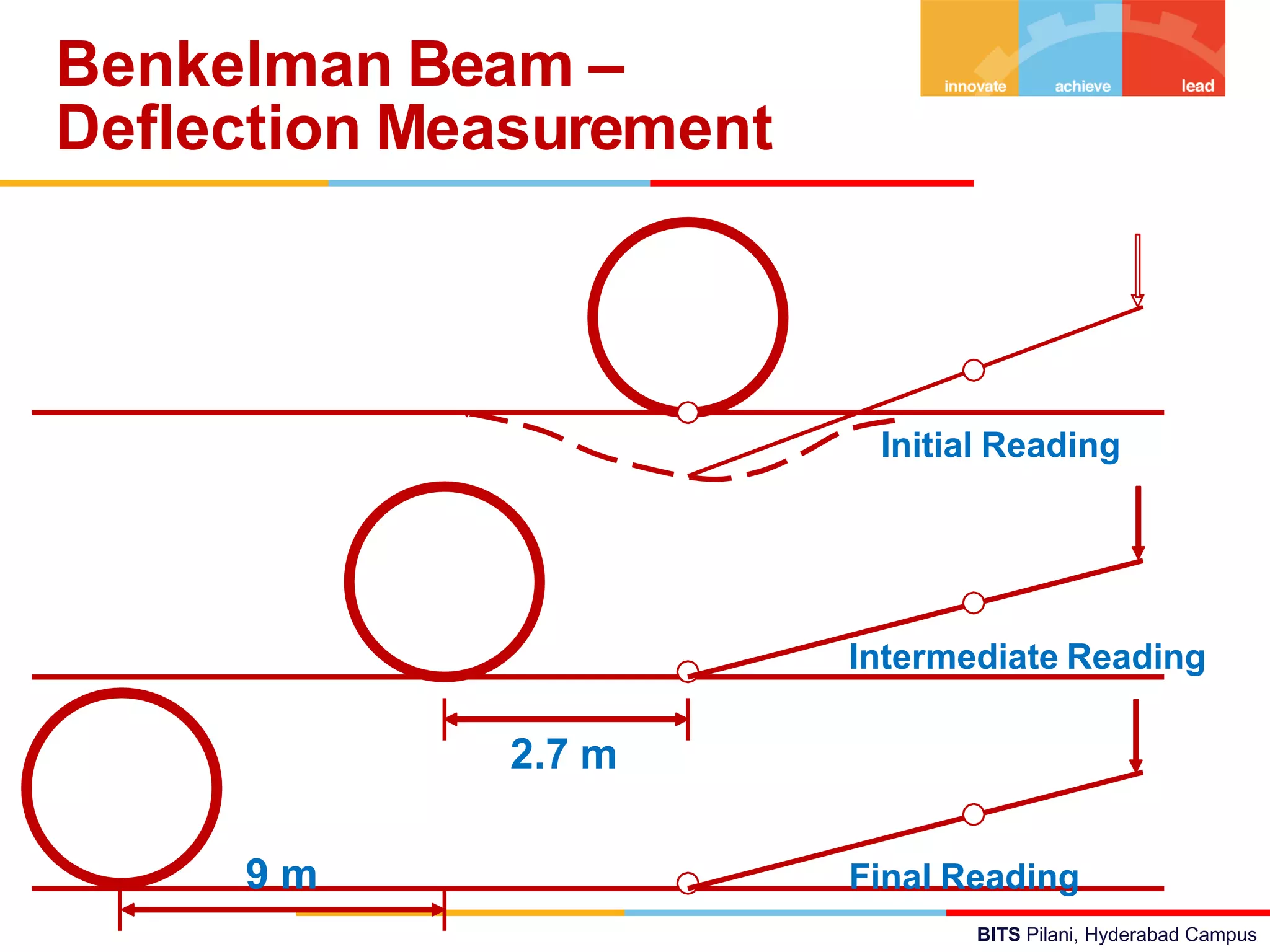

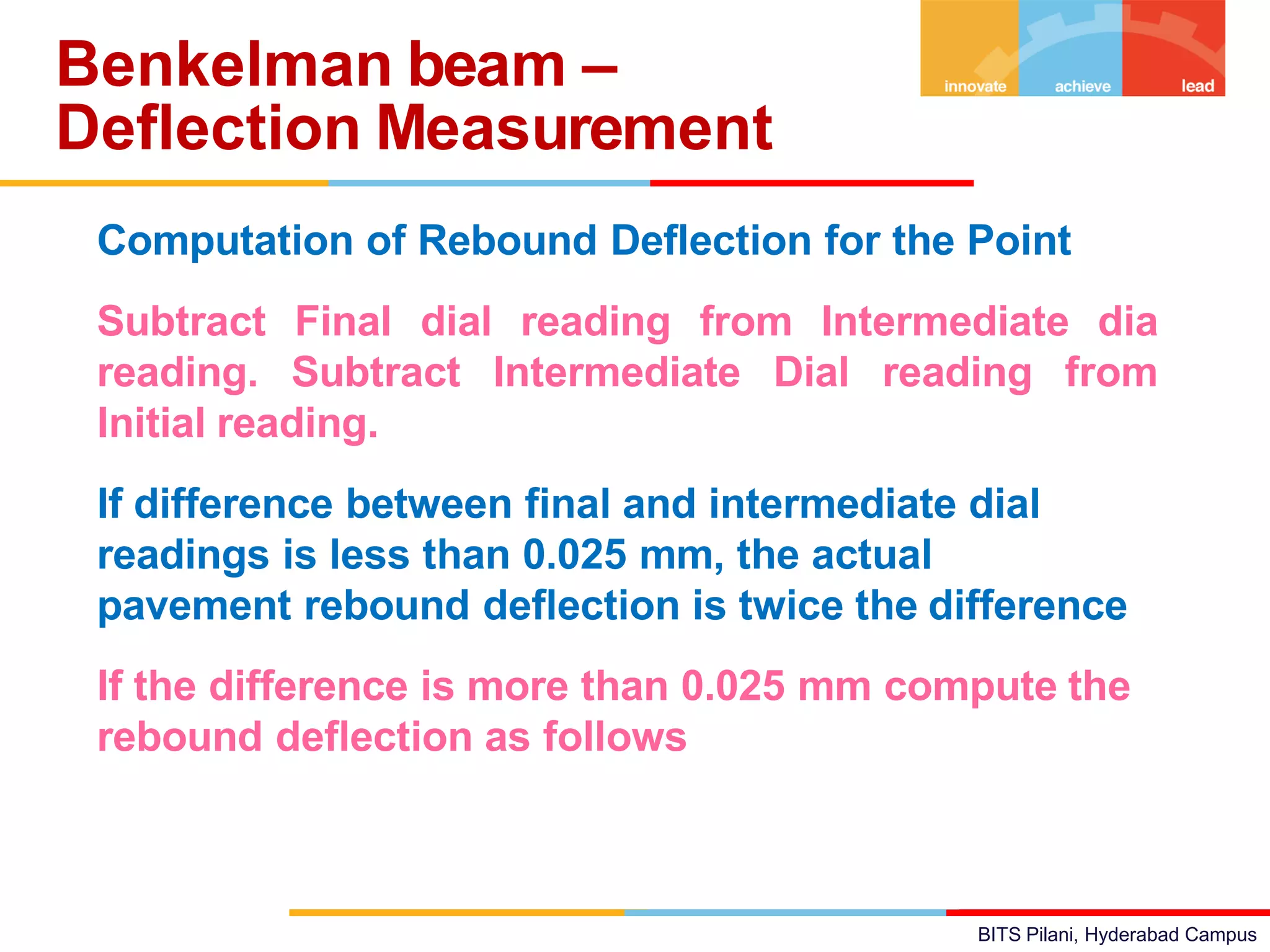

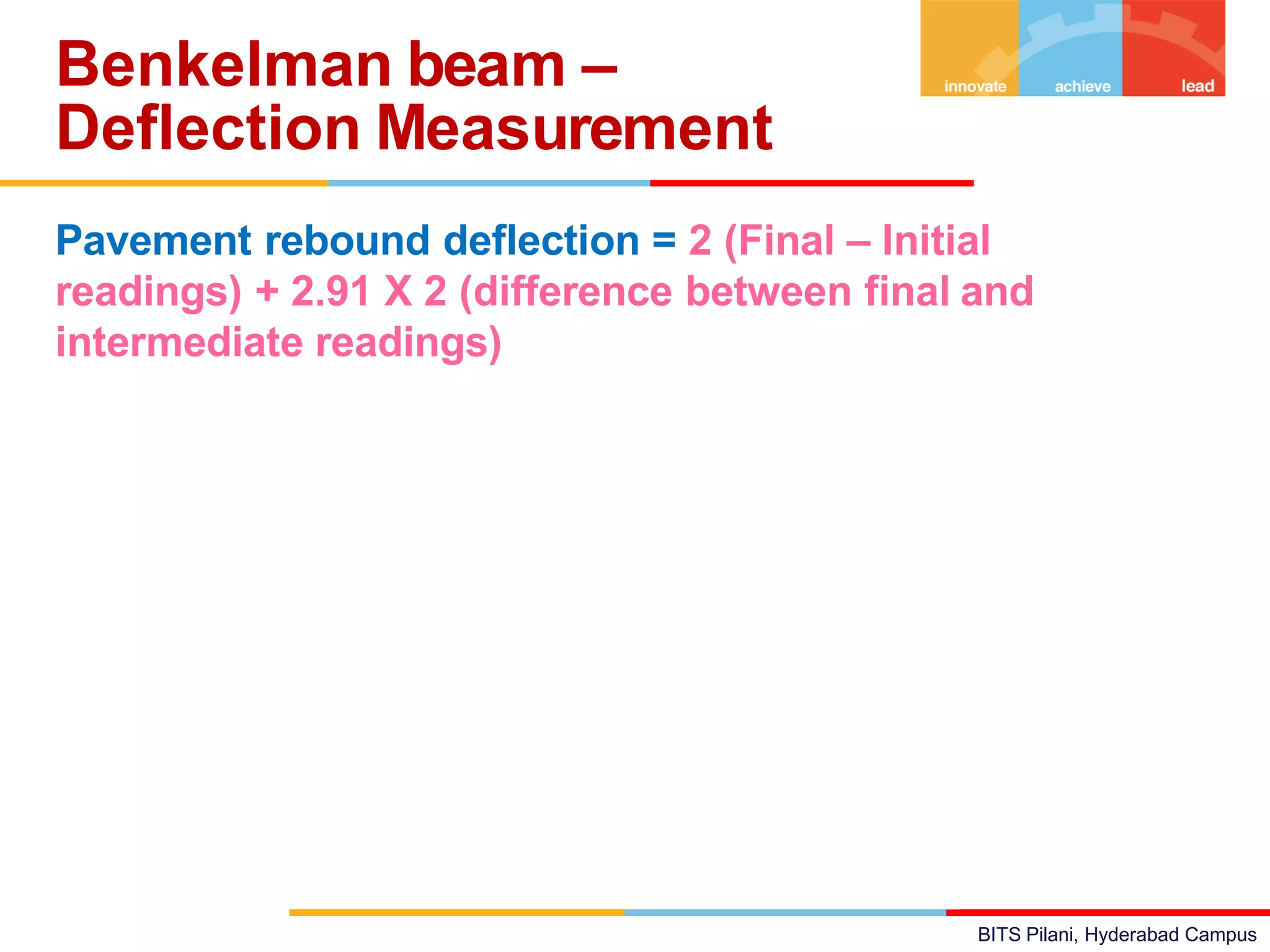

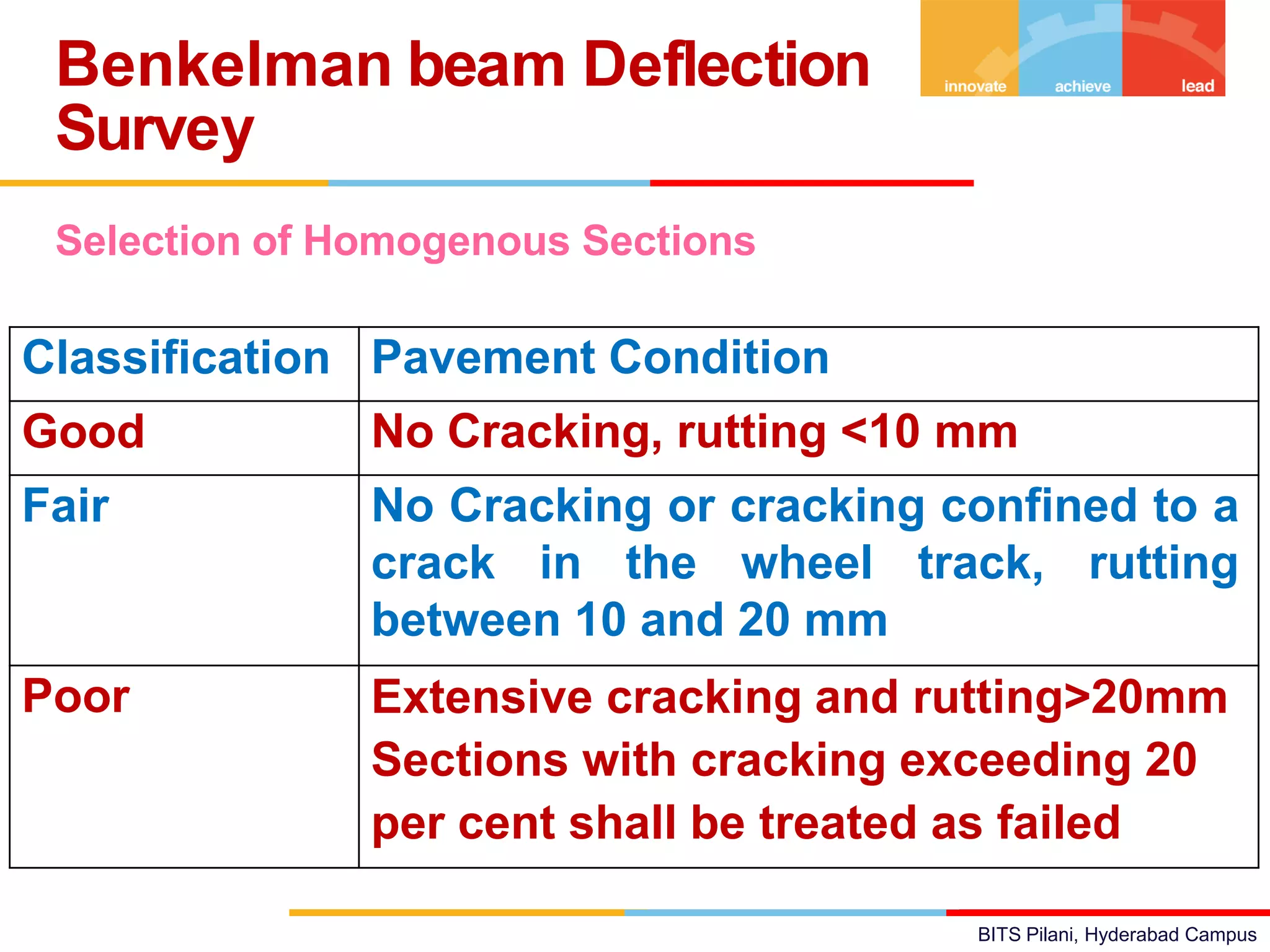

This document discusses structural evaluation of flexible pavements. It begins with acknowledgements and then provides an overview of flexible pavement layers and common distresses like rutting, cracking, raveling and potholes. It describes the roles of a pavement engineer and different types of maintenance. Both destructive and non-destructive evaluation methods are summarized, with more detail provided on the Benkelman Beam test for non-destructive deflection measurement and analysis. Guidelines from IRC and research projects on using deflection data to design overlays for pavement strengthening are also summarized.

![BITS Pilani, Hyderabad Campus

Evaluation of Pavement Performance

Functional Performance: The ability of pavement to

provide comfortable, safe, economical riding quality

to the road users.

[Pavement Condition Index (PCI), roughness, skid resistance]

Structural Performance: Related to the load carrying

capacity of the pavement.

[Pavement response to load application]

PavementEvaluation](https://image.slidesharecdn.com/pavementevaluationlecture-iahe-230528023148-2a831c9a/75/Pavement-Evaluation-Lecture-IAHE-pdf-13-2048.jpg)

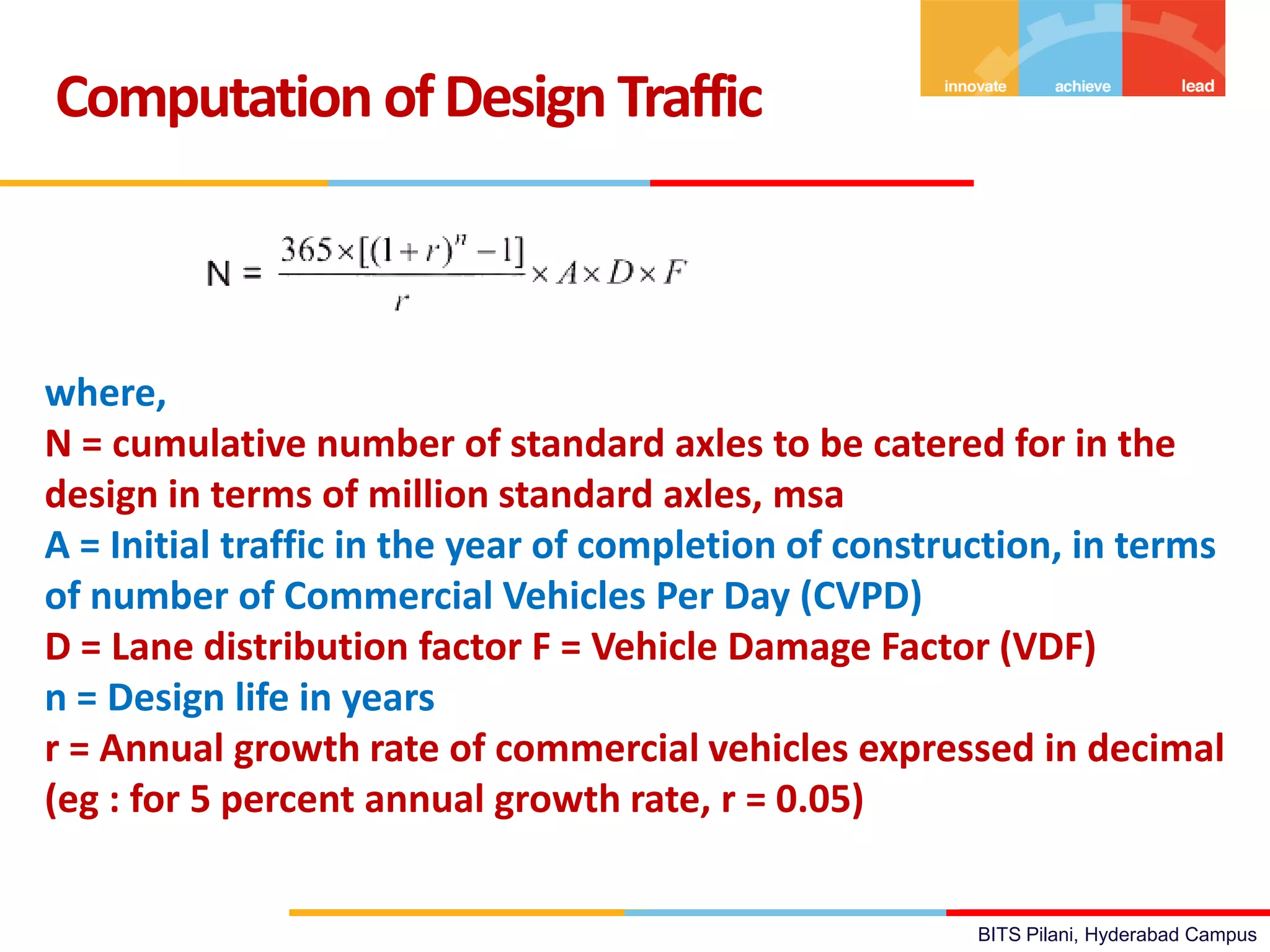

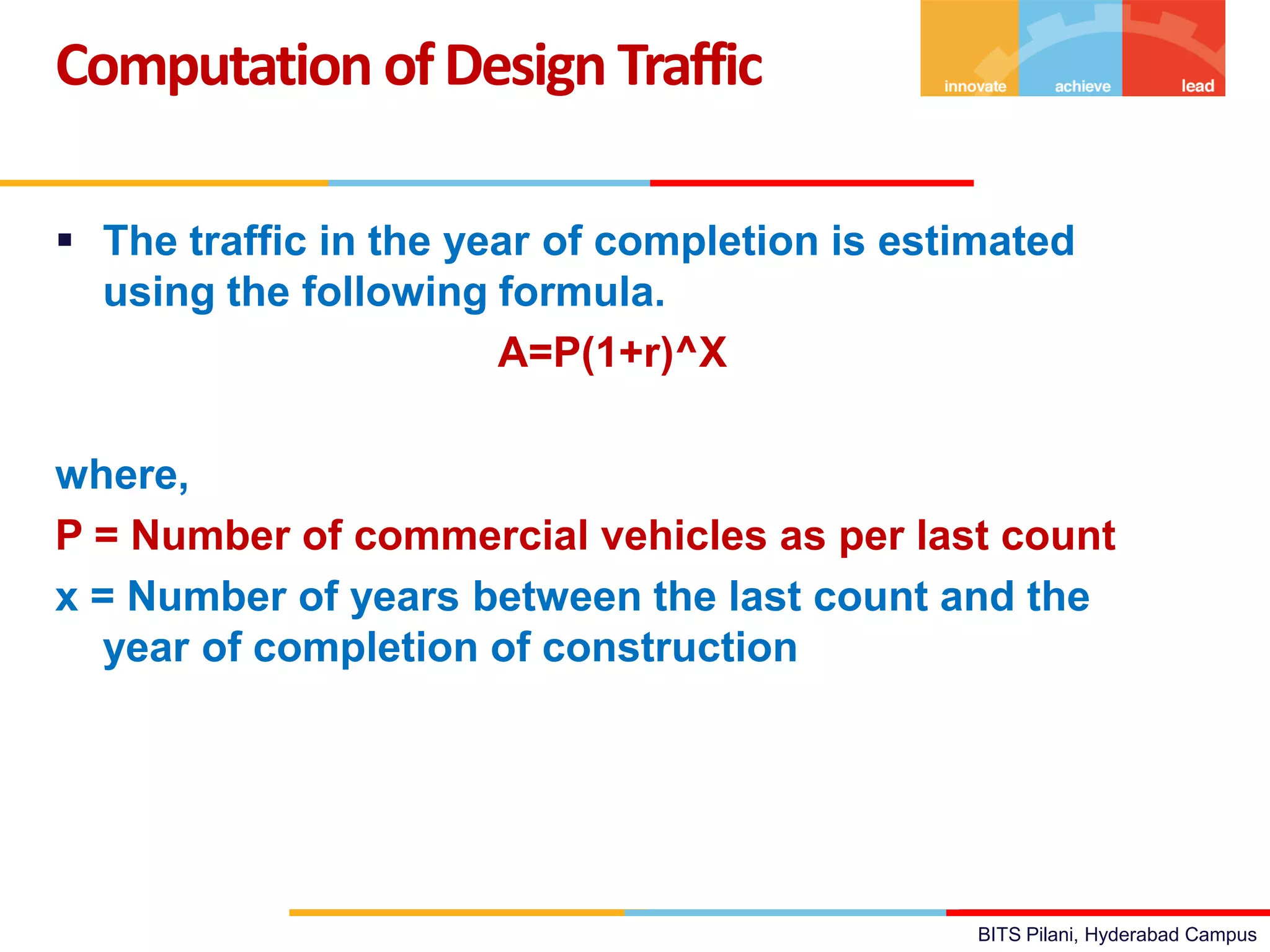

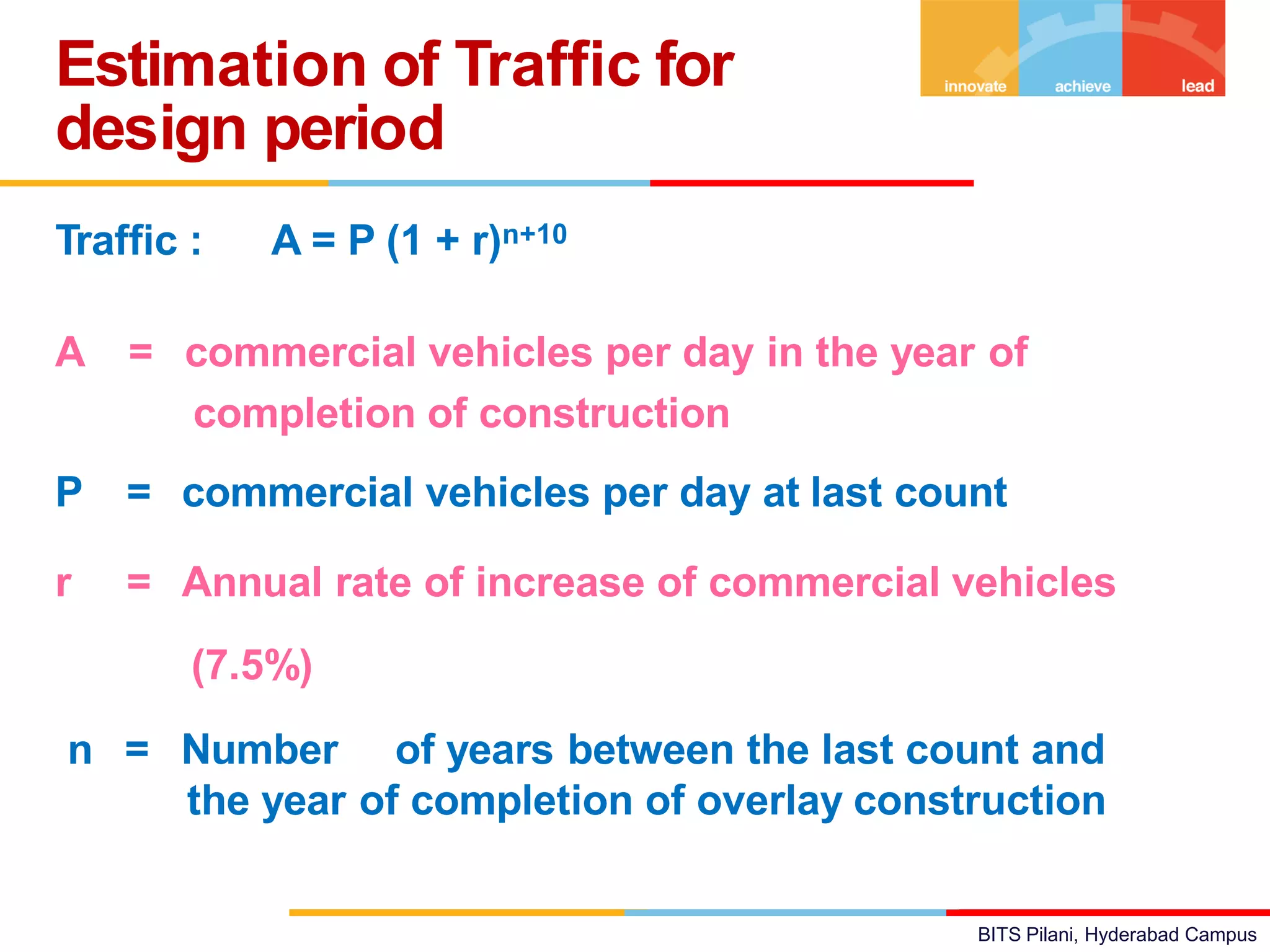

![BITS Pilani, Hyderabad Campus

= 365 x A [(1+ r)x – 1] x F

-----------------------------

r

Where N = cumulative number of standard axles to be catered for

during the design period

A = Initial traffic in the year of completion of construction

modified to account for the lane distribution

r = Annual rate of growth of commercial vehicles (7.5%) x =

X= Design life, years (10 for major roads, 5 for less important roads)

F = Vehicle Damage Factor

Estimation of Traffic for

design period](https://image.slidesharecdn.com/pavementevaluationlecture-iahe-230528023148-2a831c9a/75/Pavement-Evaluation-Lecture-IAHE-pdf-59-2048.jpg)