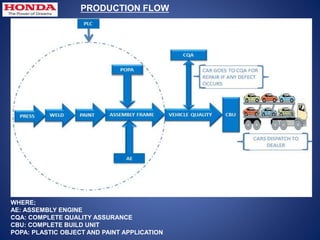

The document provides information about Honda Cars India Limited's summer internship presentation. It discusses Honda's global operations and history. It then focuses on Honda's manufacturing unit in India, located in Tapukara, Rajasthan. The production flow and various production shops like Press, Aluminum, Engine, Paint, and Assembly are described. Key aspects of the Engine Assembly shop like the assembly line layout, tools and equipment used, and assembly processes followed are explained in detail.