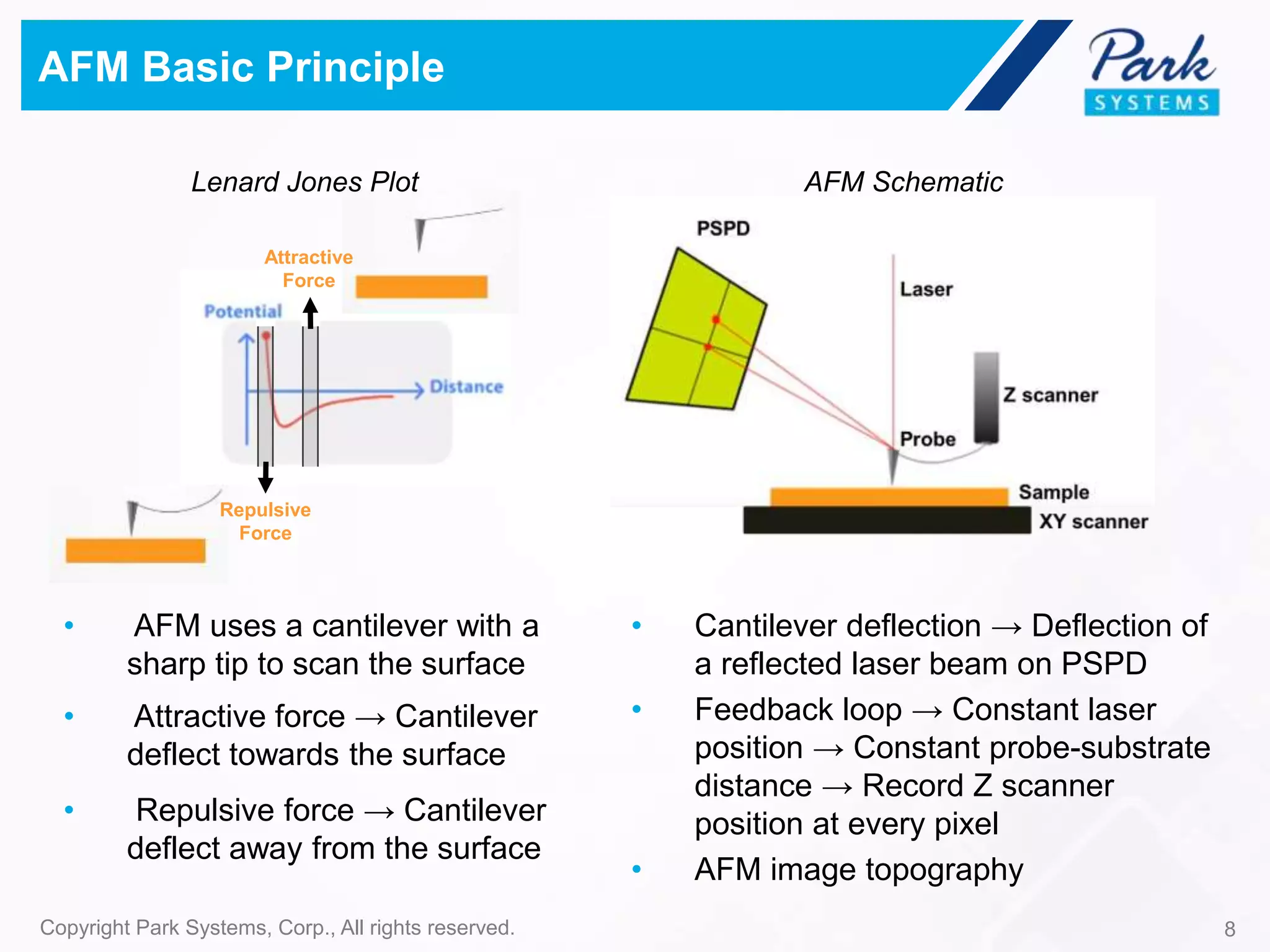

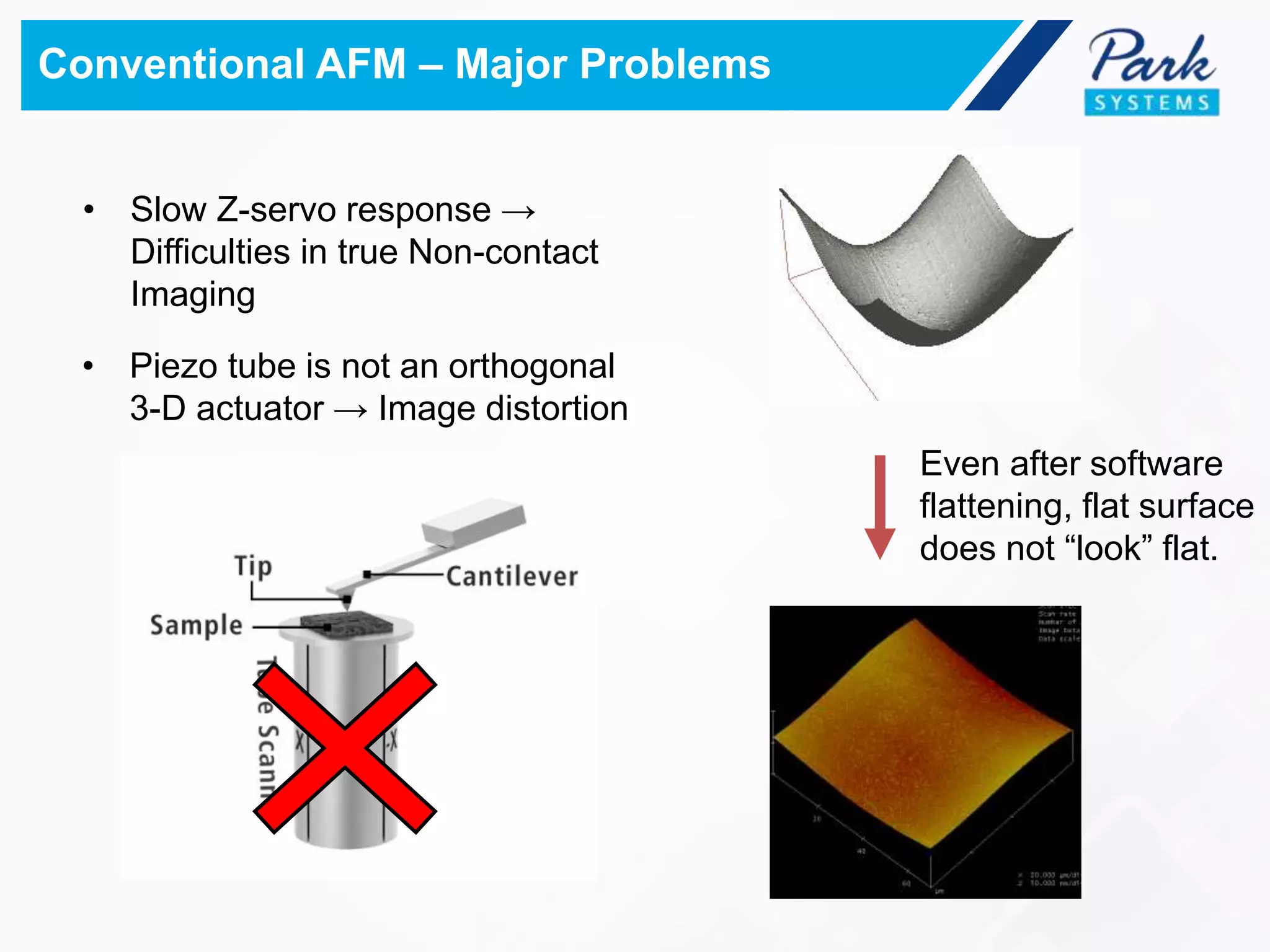

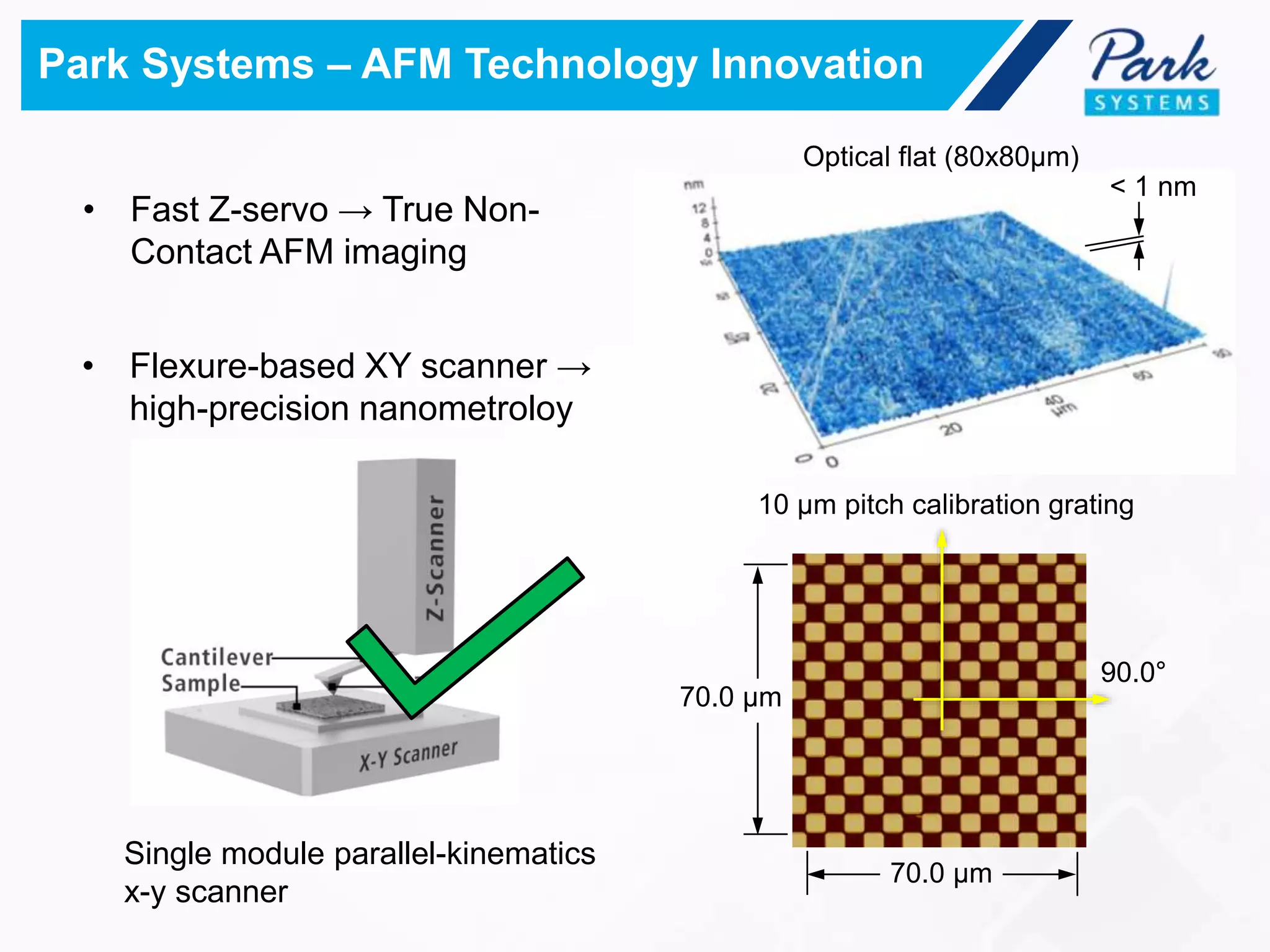

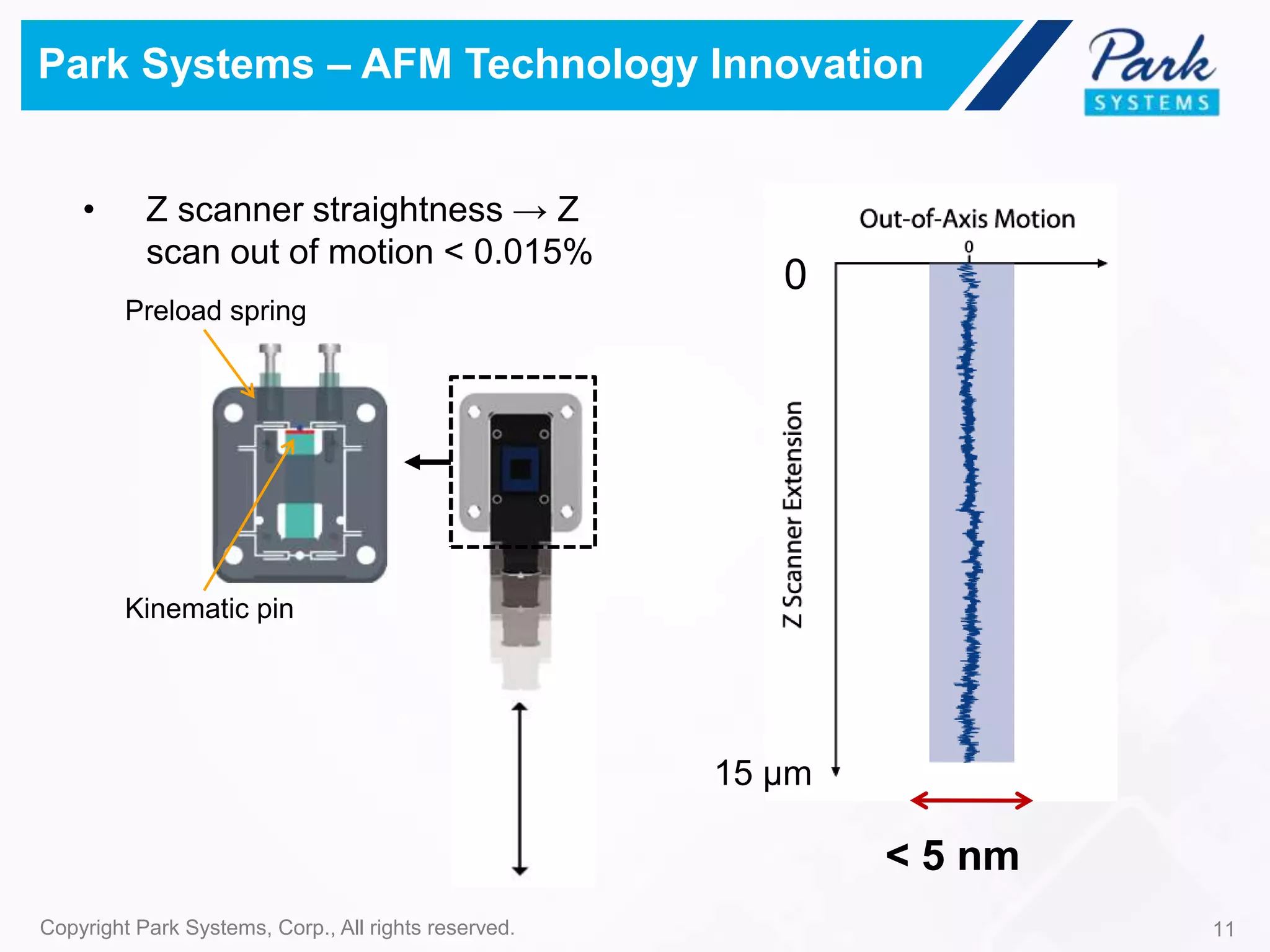

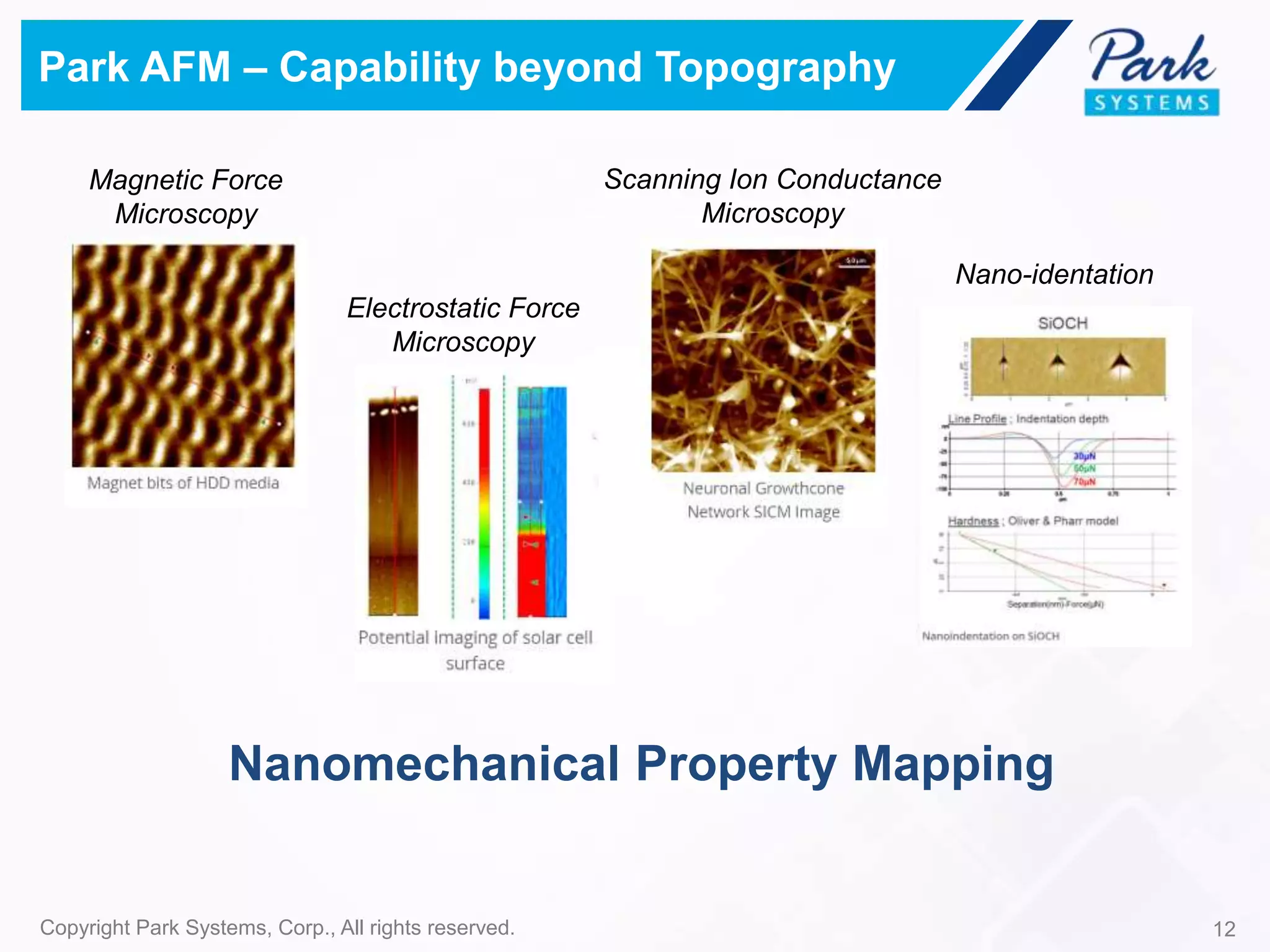

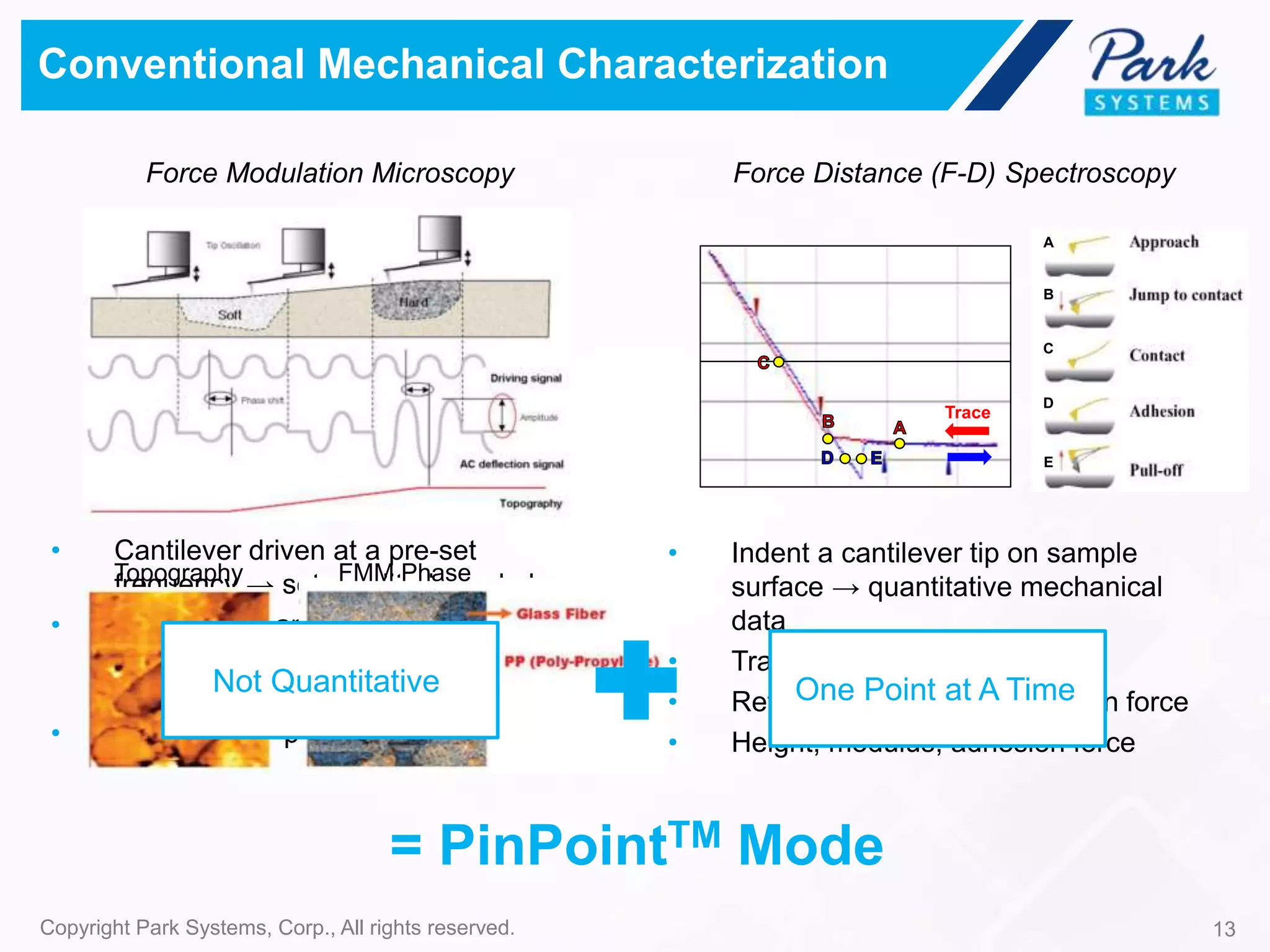

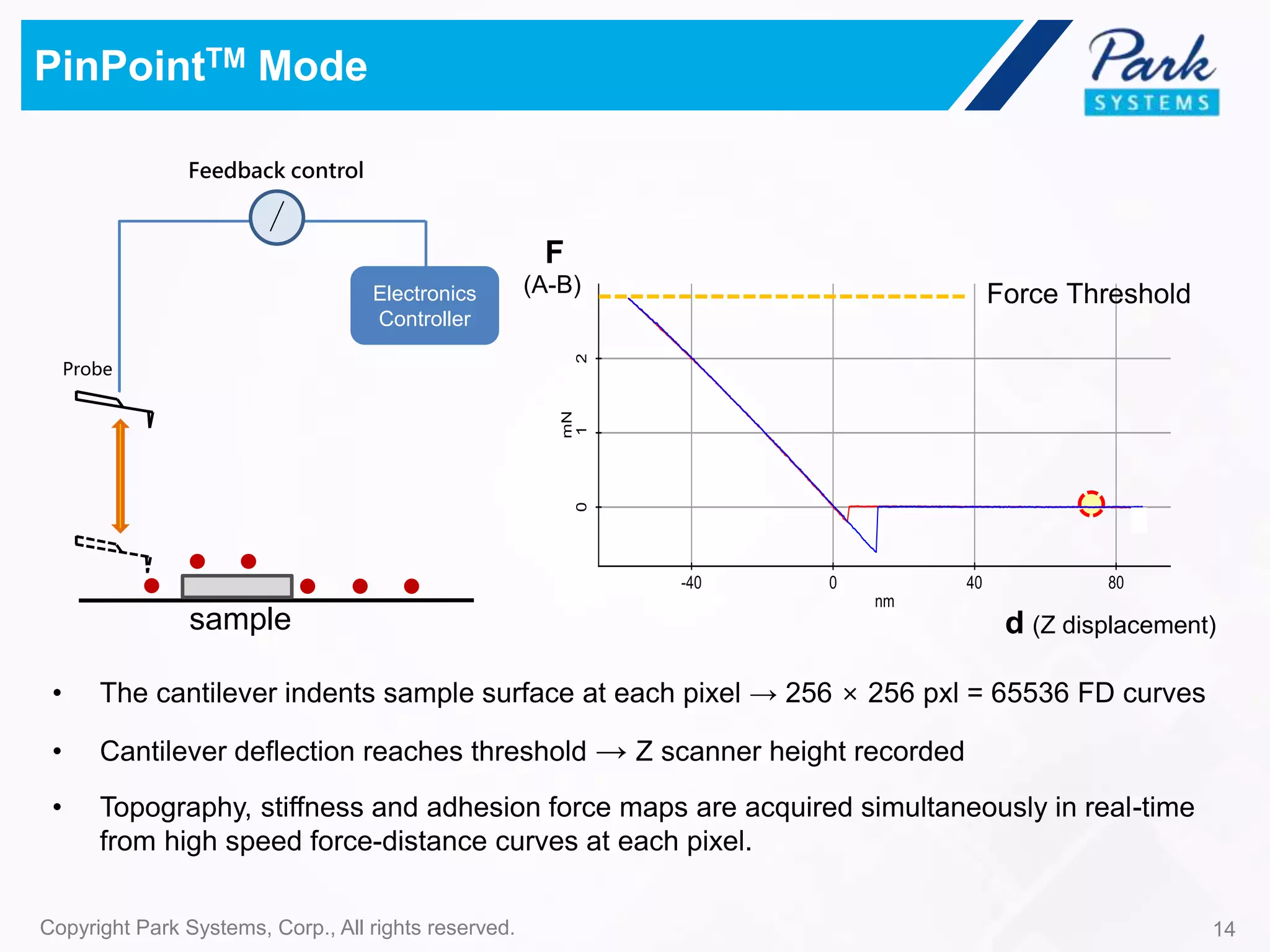

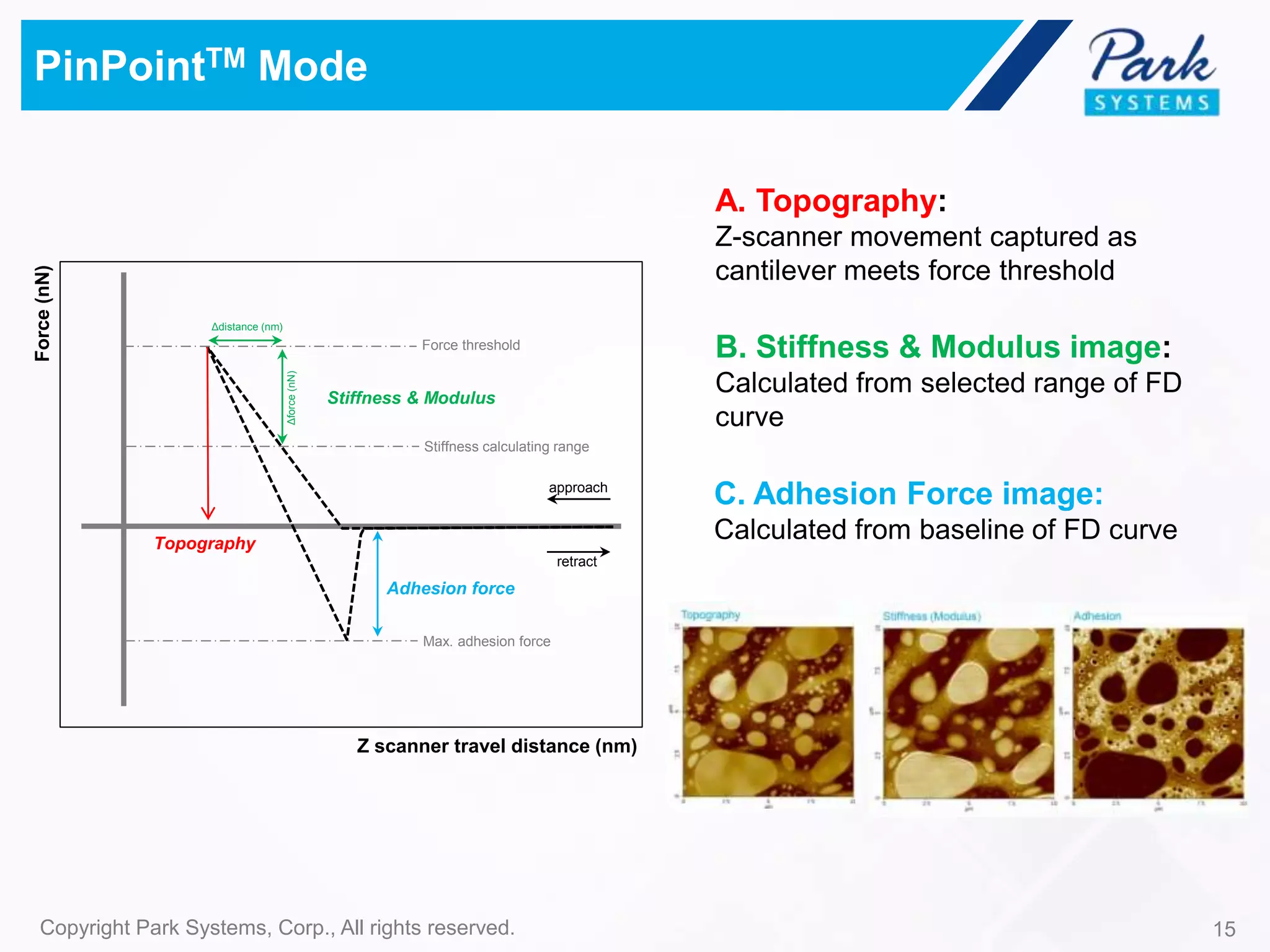

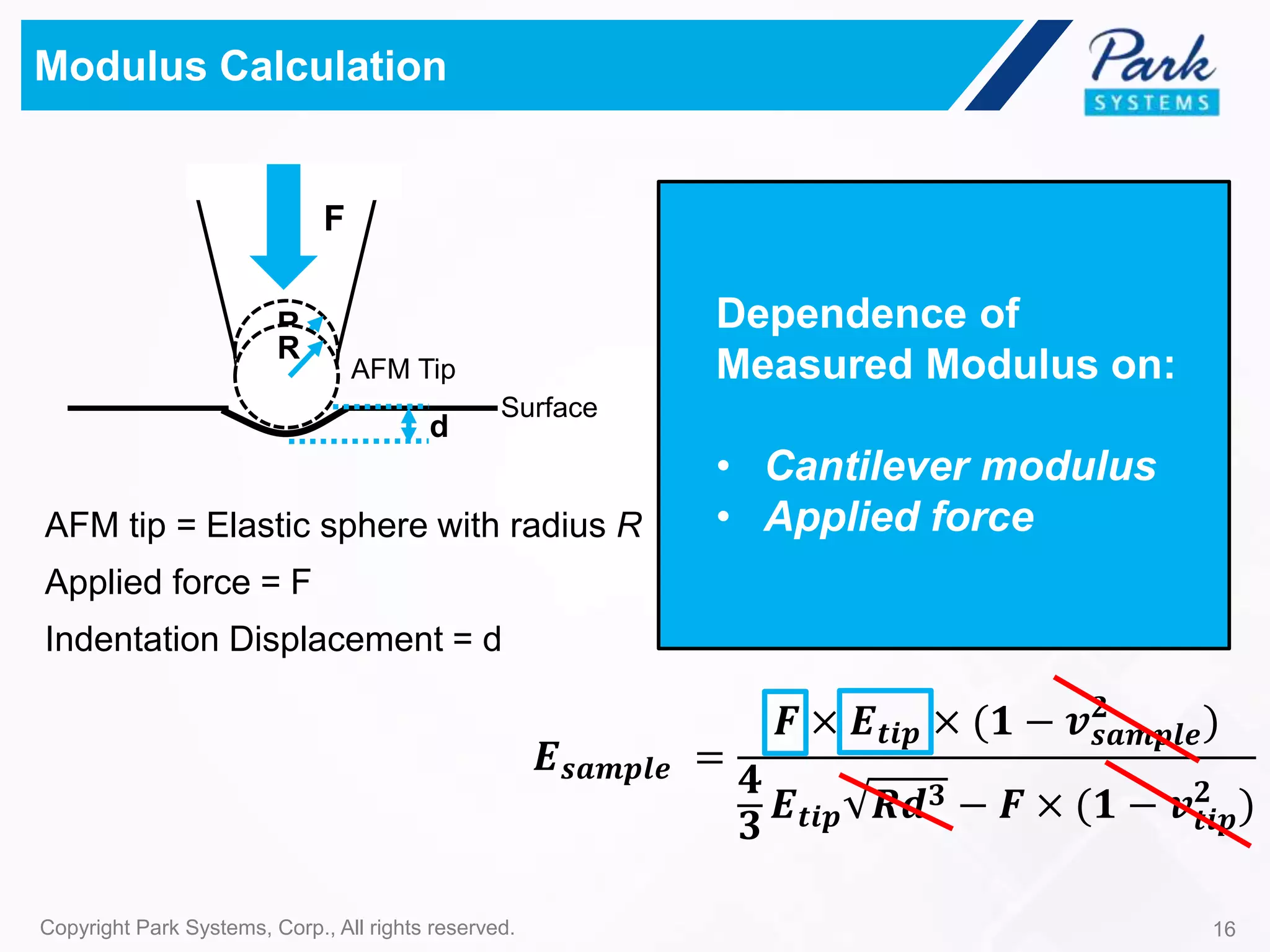

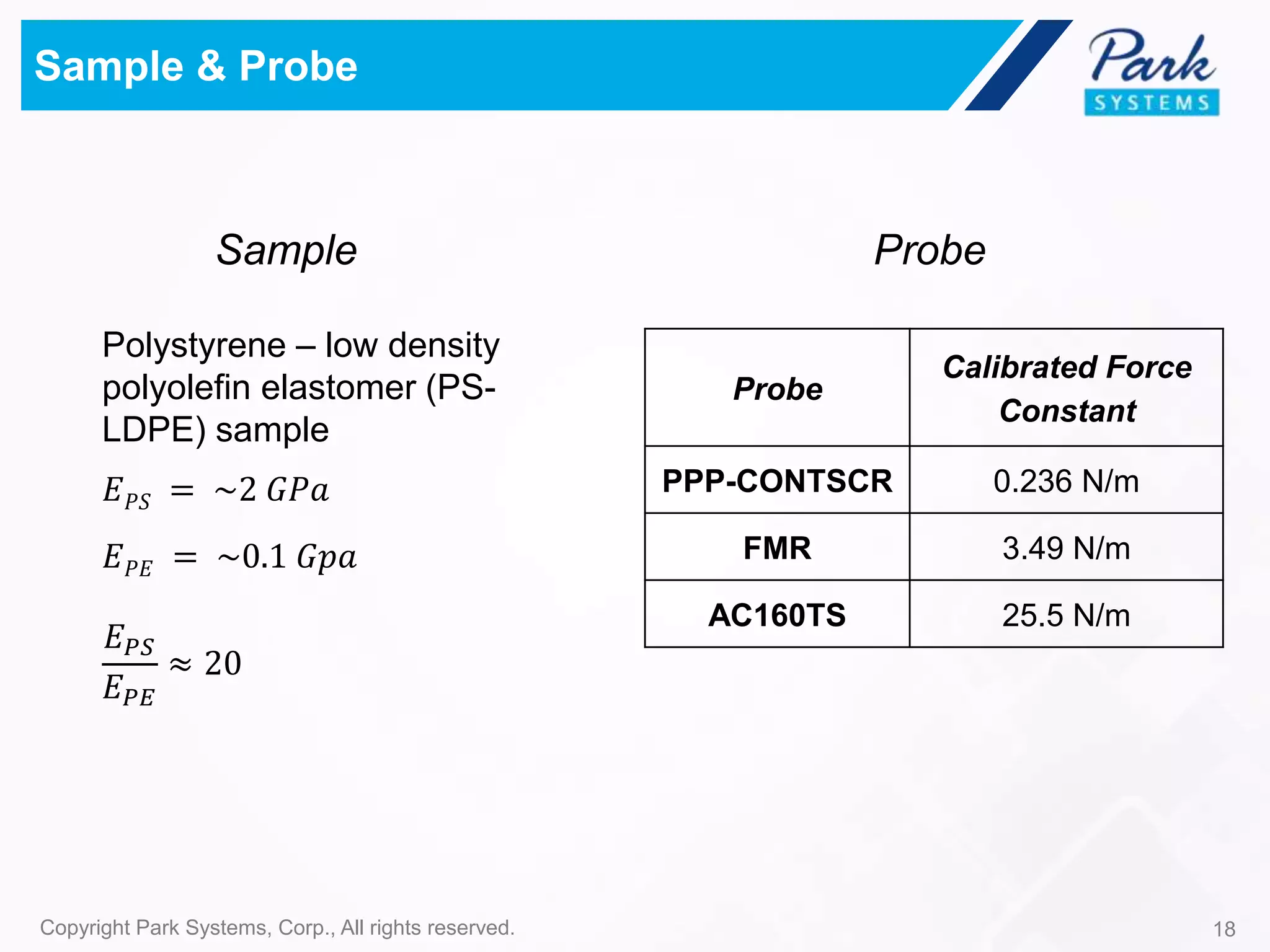

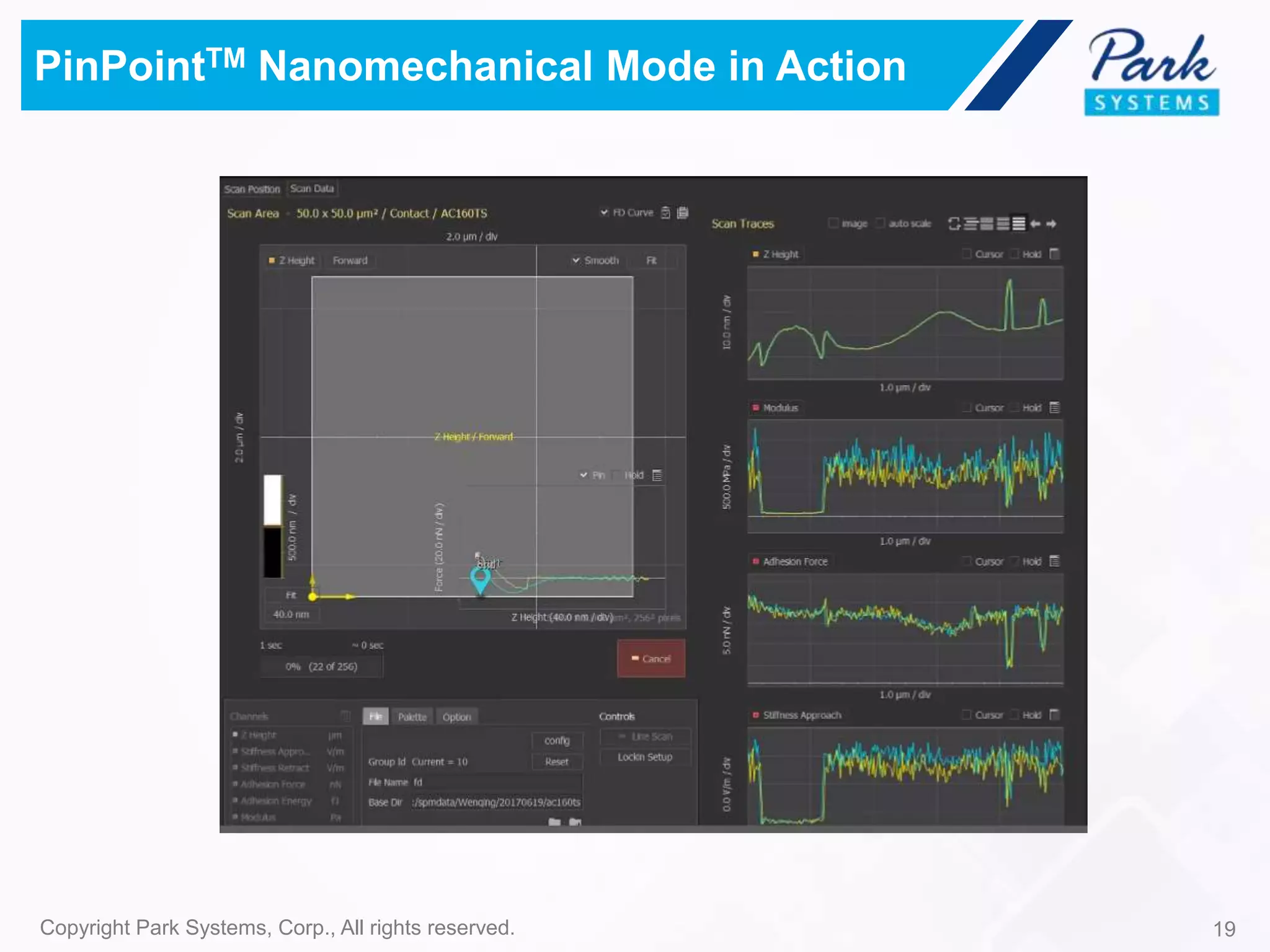

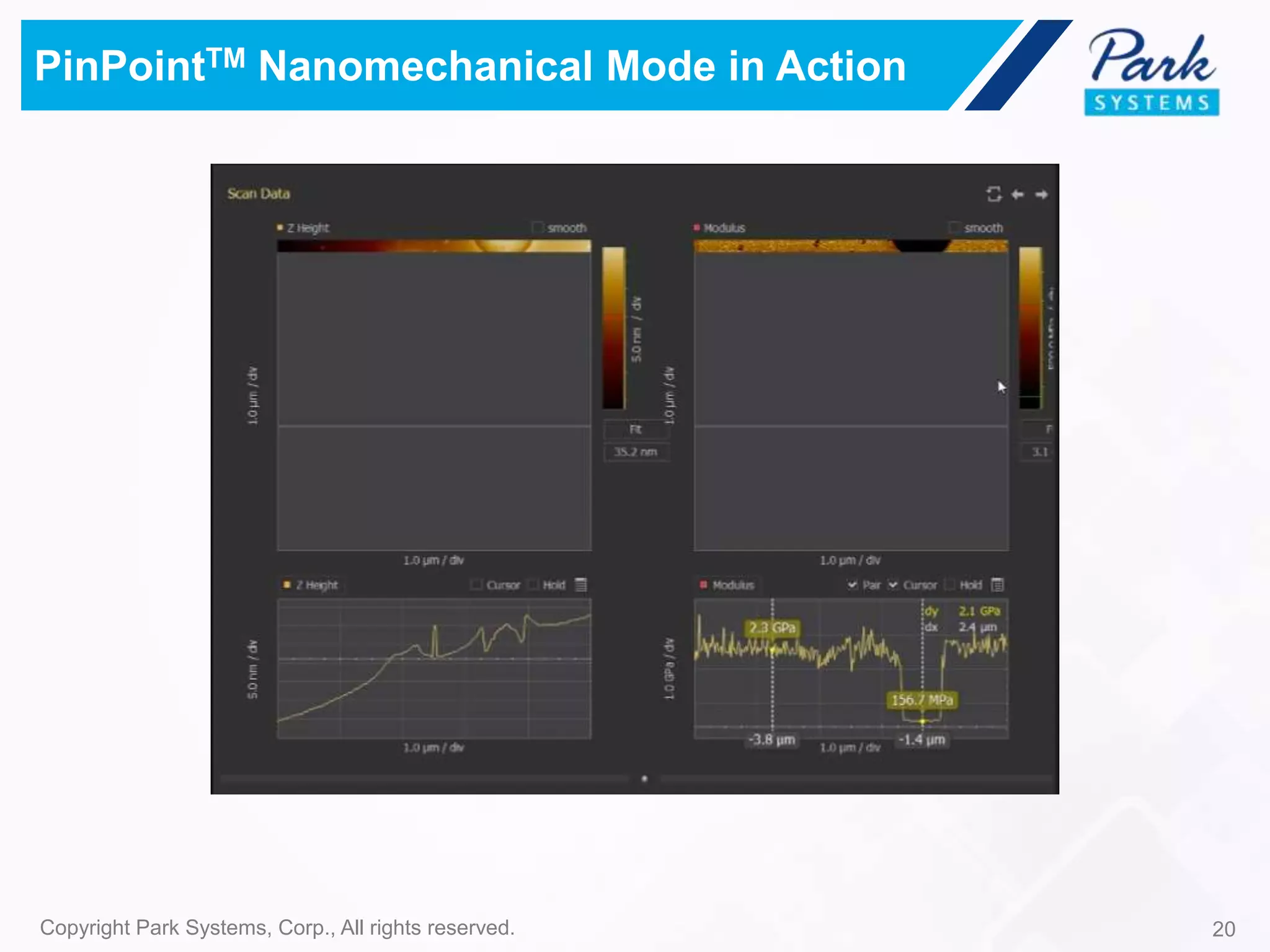

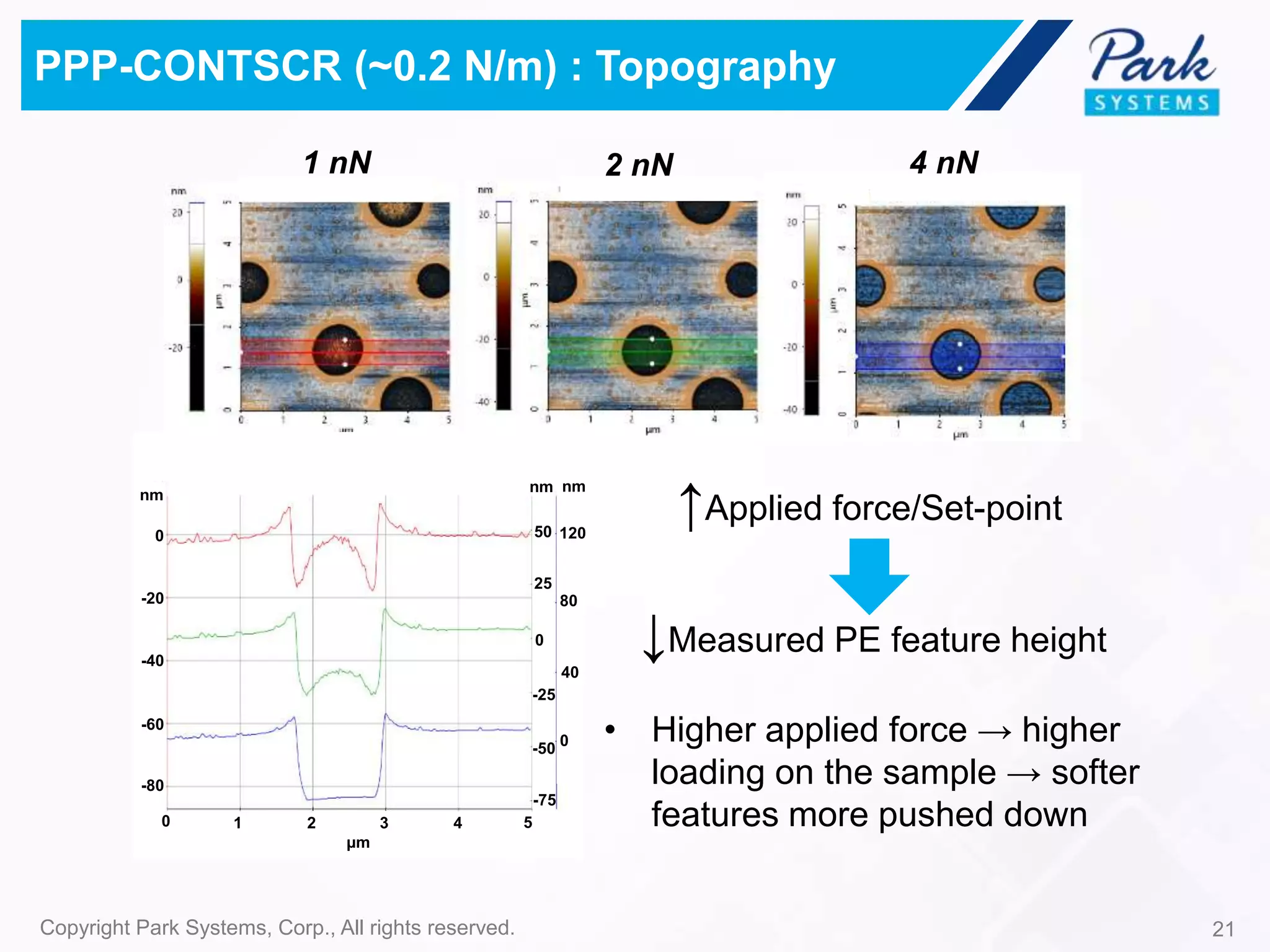

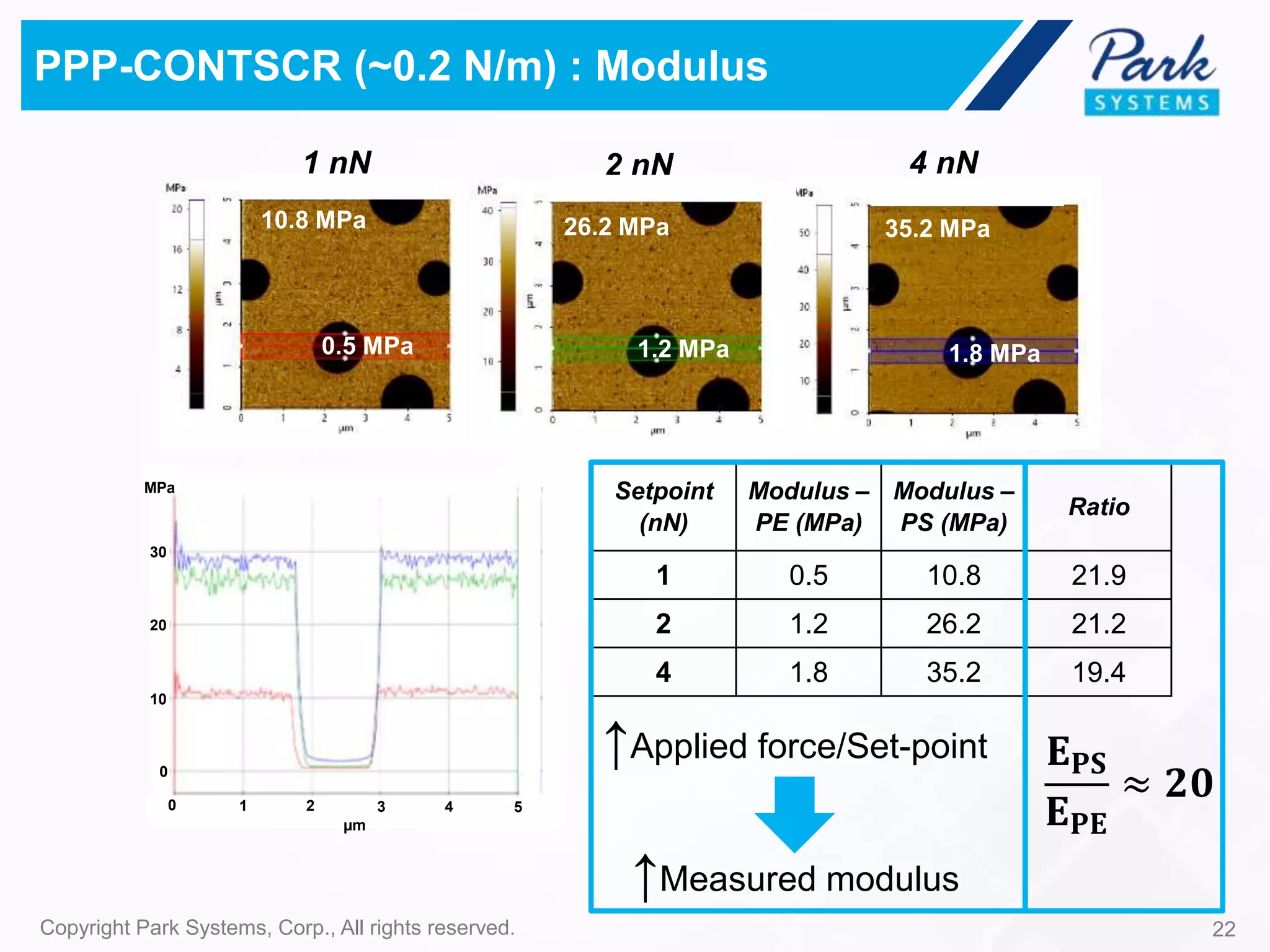

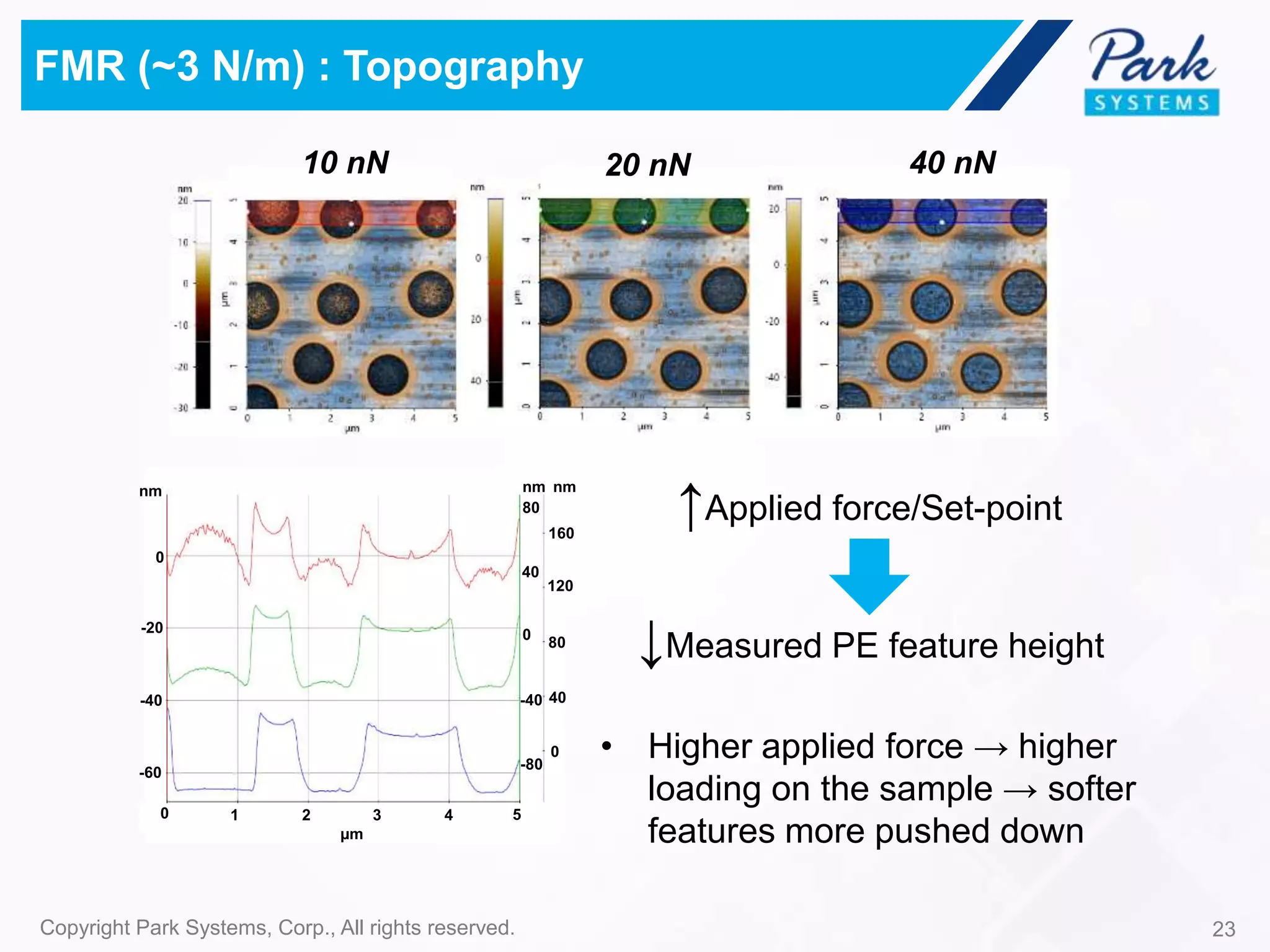

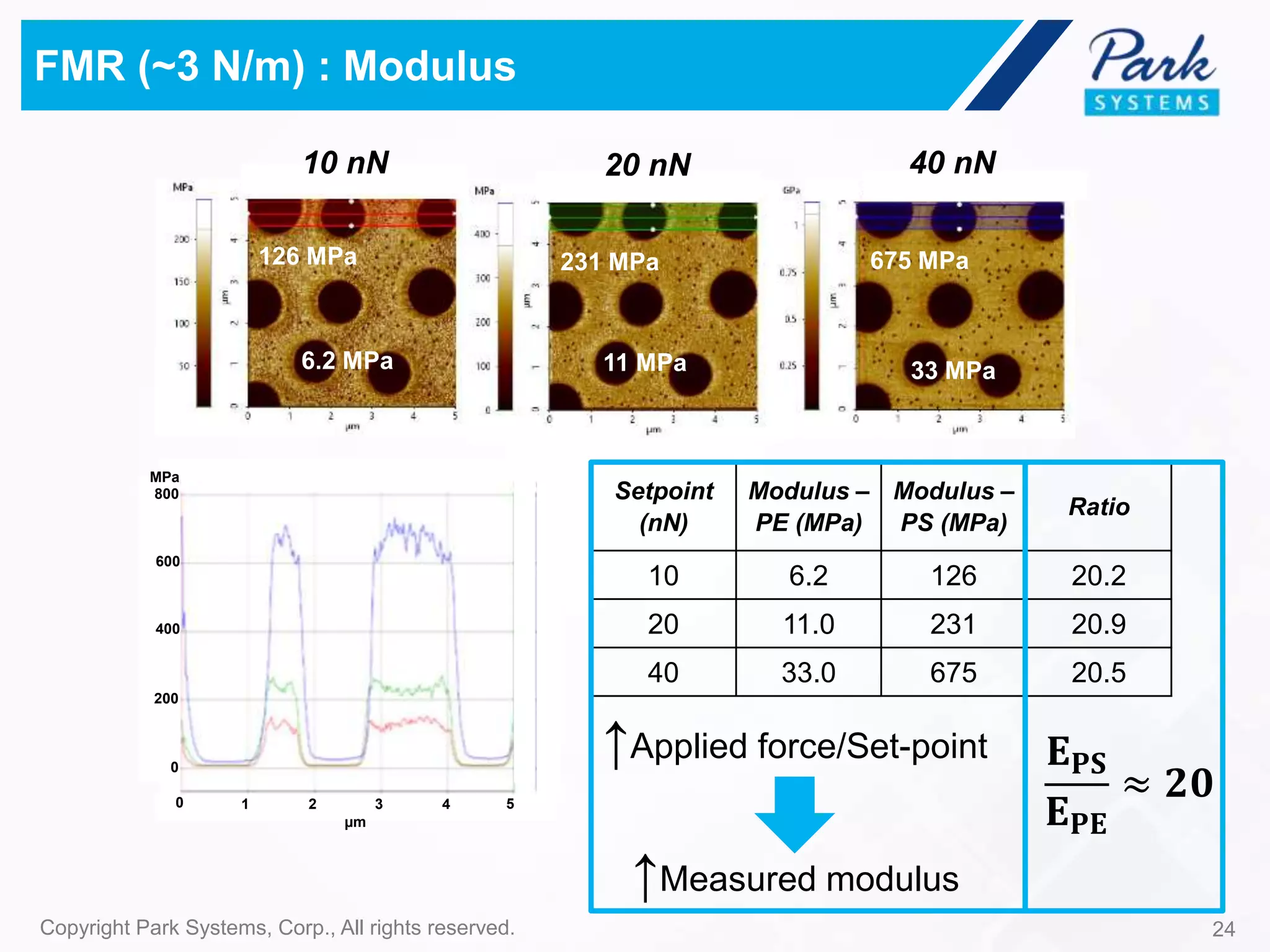

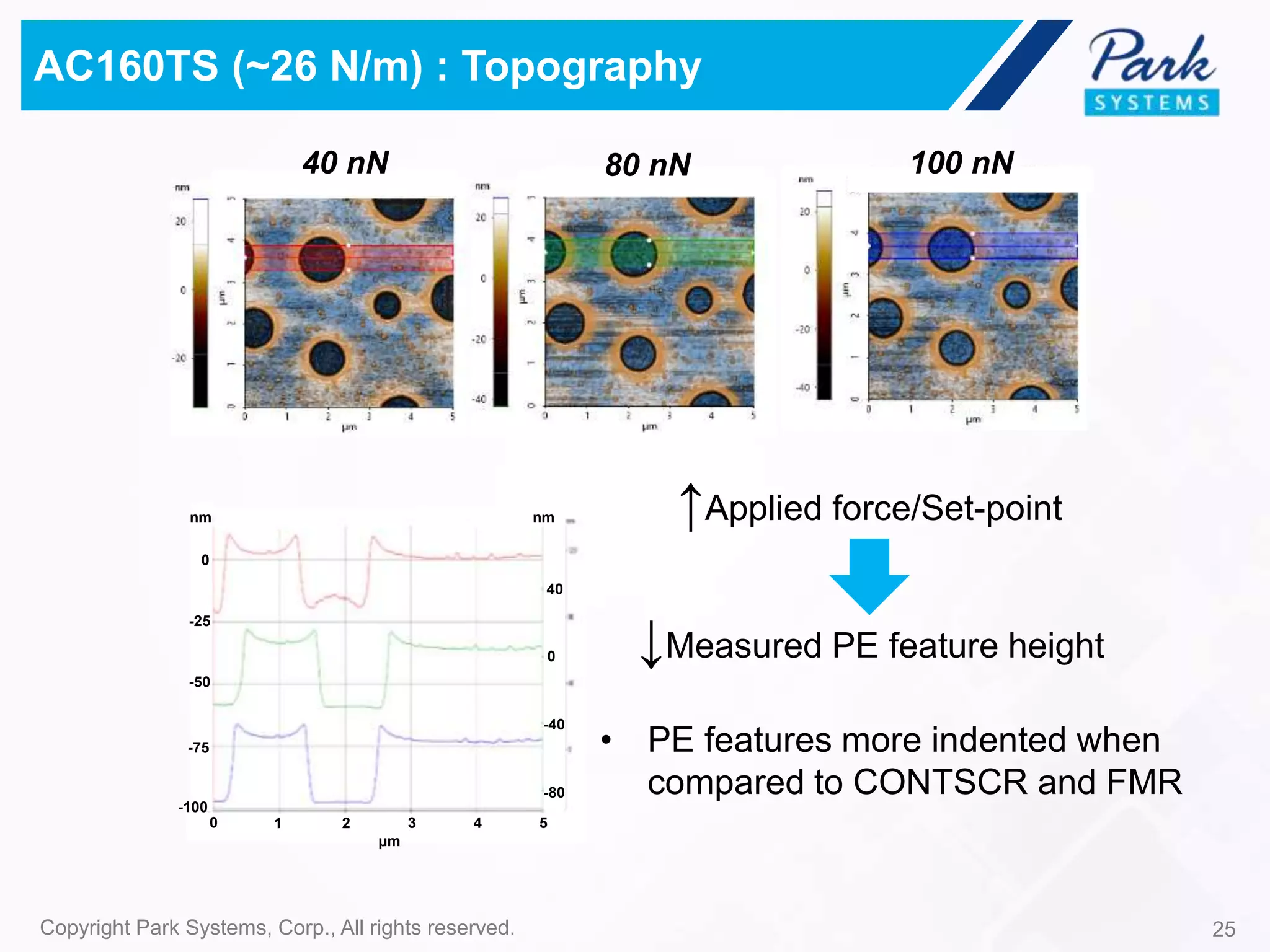

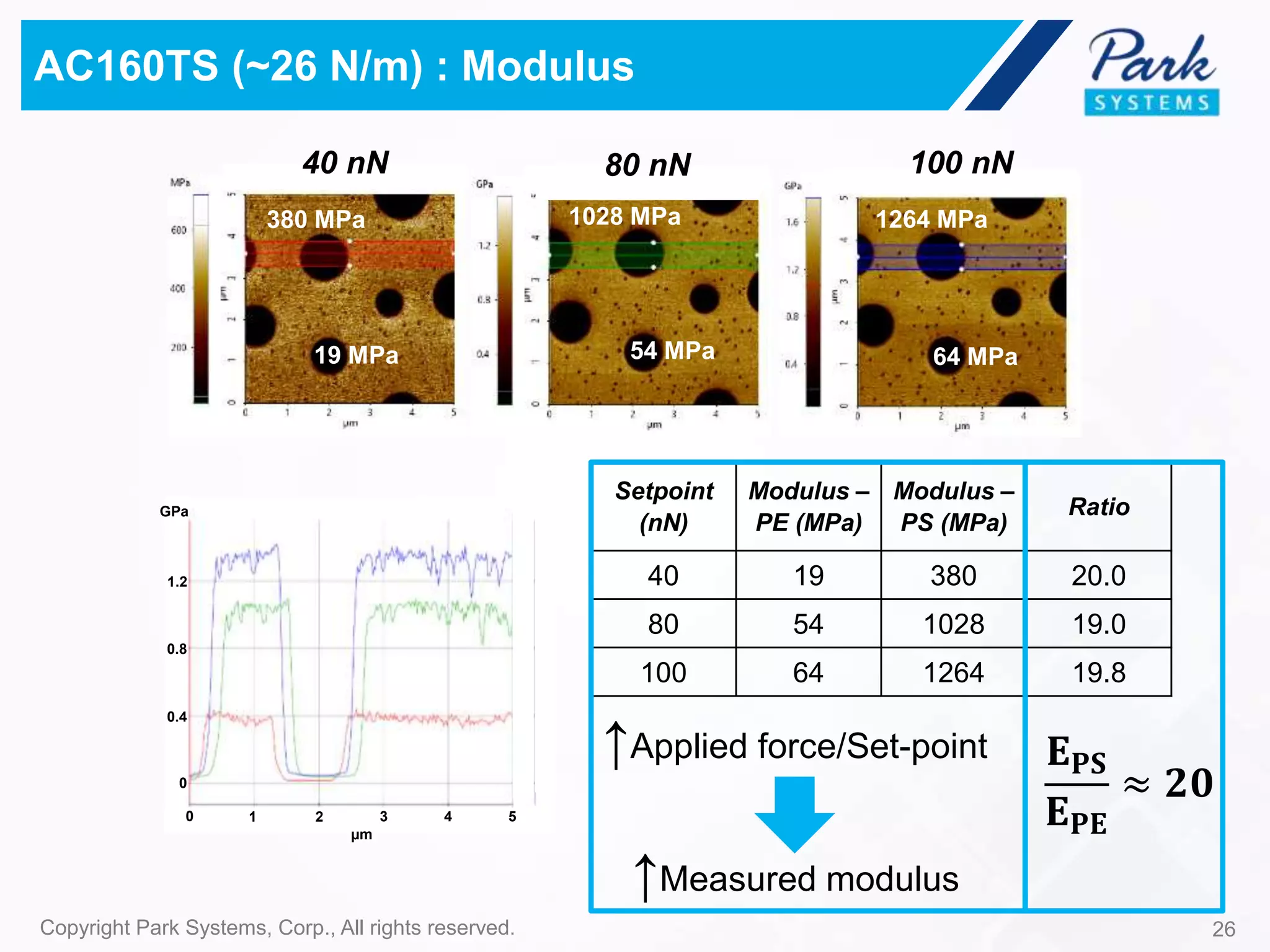

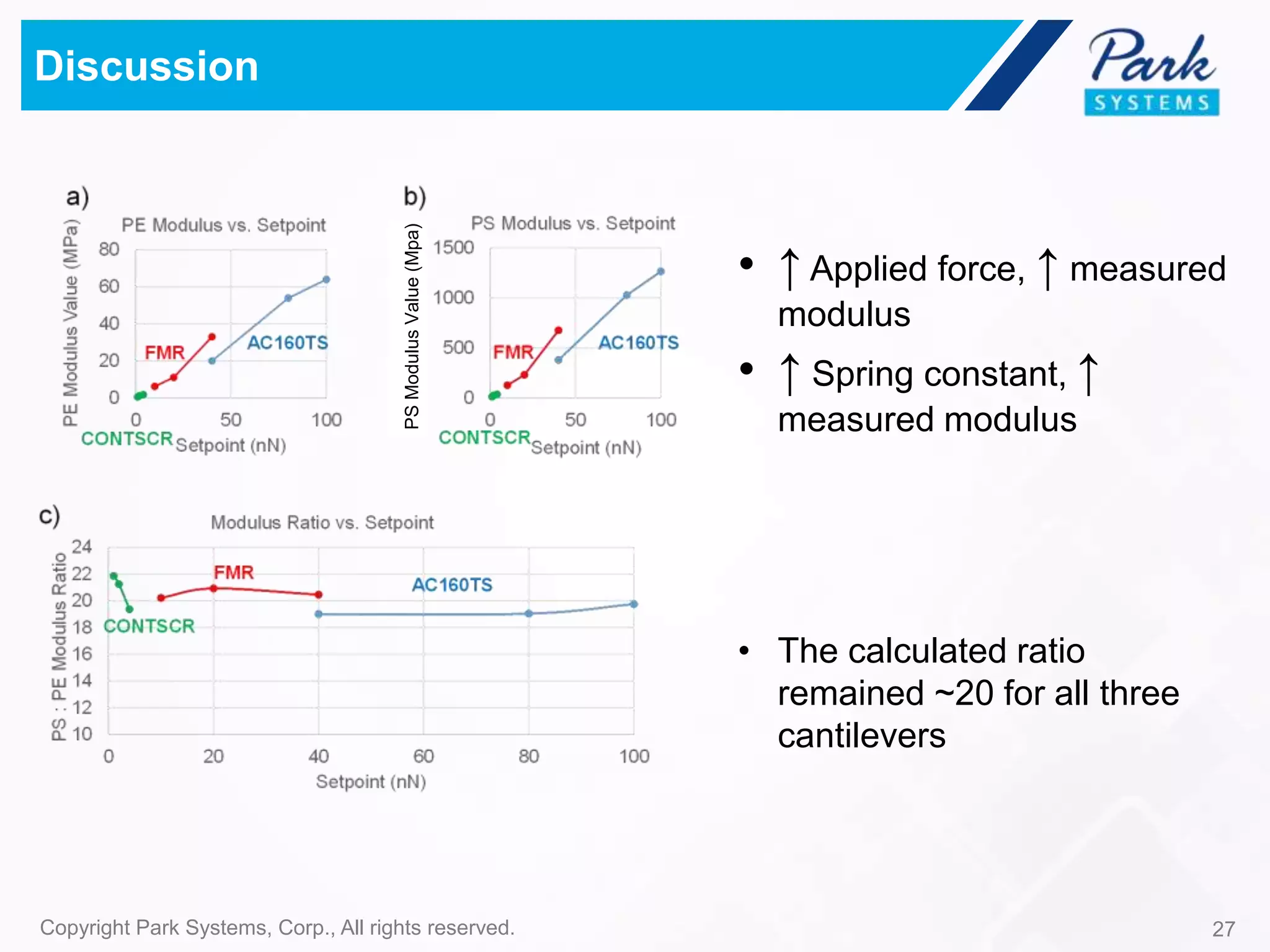

The document discusses the capabilities of Park Systems' Pinpoint Nanomechanical Mode using Atomic Force Microscopy (AFM) for nanoscale modulus mapping, emphasizing its precision and ease of use. It details the mechanism of AFM, the innovations that enhance non-contact imaging, and the ability to obtain topography, stiffness, and adhesion force maps simultaneously in real time. The results indicate that measured modulus values increase with applied force and the cantilever's force constant, establishing the effectiveness of the Pinpoint mode in assessing relative sample modulus ratios.