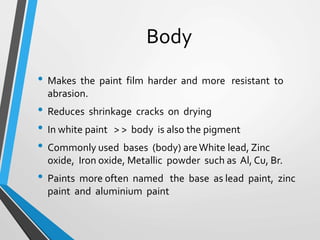

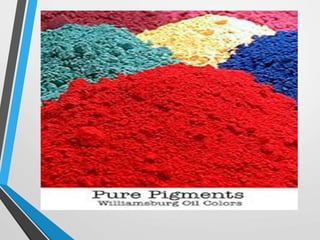

Group 5 presented on the properties of paints and their composition. Their presentation covered the key components of paint including the body, vehicle, pigment, thinner, and dryers. They discussed various types of paints and how they are formulated. They also showed an example of a well-decorated bedroom using different paints.