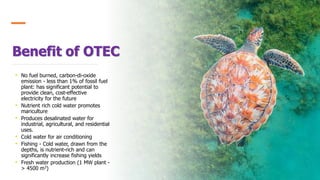

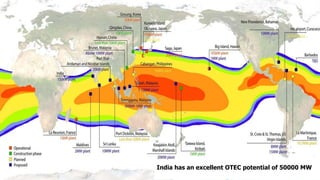

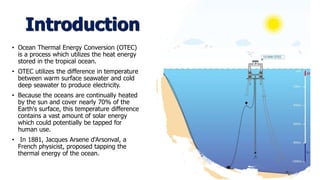

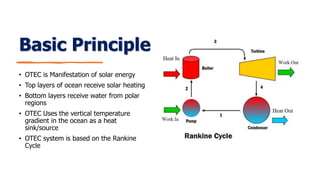

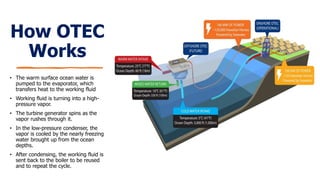

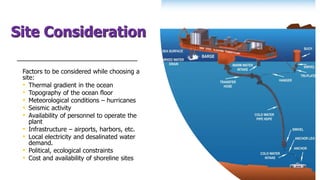

Ocean Thermal Energy Conversion (OTEC) utilizes the temperature difference between warm surface seawater and cold deep seawater to produce electricity via a Rankine cycle. It can also desalinate water and support mariculture. OTEC uses the sun's heating of the ocean's top layers and input of cold water from polar regions to create a heat source and sink. While offering clean energy, OTEC is limited to tropical ocean sites and has high capital costs, with no systems yet demonstrated at full scale long-term.

![Refrigeration

and Air-

Conditioning

• The cold [5°C (41ºF)]

seawater made available by

an OTEC system creates an

opportunity to provide large

amounts of cooling to

operations that are related to

or close to the plant.

• The cold seawater delivered

to an OTEC plant can be

used in chilled-water coils to

provide air-conditioning for

buildings.](https://image.slidesharecdn.com/otec-210626034219/85/Ocean-Thermal-Energy-Conversion-14-320.jpg)