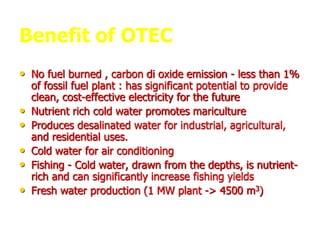

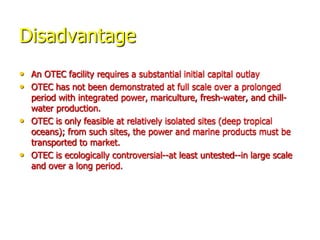

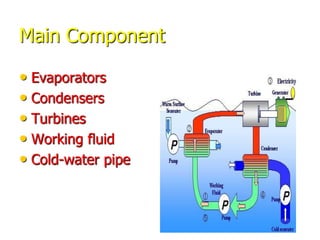

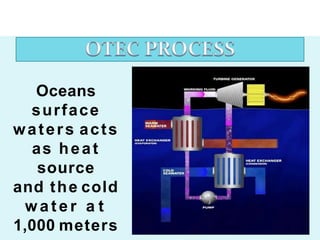

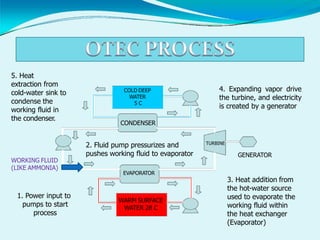

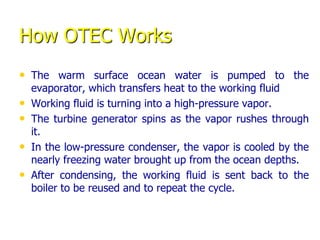

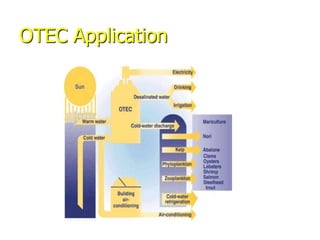

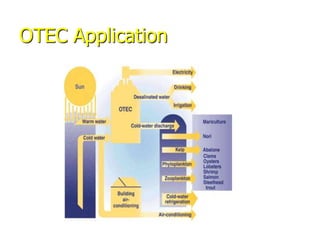

Ocean Thermal Energy Conversion (OTEC) utilizes the temperature difference between warm surface seawater and cold deep seawater to produce electricity via a heat engine. OTEC can also be used to generate desalinated water, support aquaculture, and provide refrigeration. While OTEC has potential benefits like being carbon-free, challenges include high capital costs and lack of demonstration at full commercial scale.

![Refrigeration and Air-Conditioning

• The cold [5°C (41ºF)] seawater made available

by an OTEC system creates an opportunity to

provide large amounts of cooling to operations

that are related to or close to the plant.

• The cold seawater delivered to an OTEC plant

can be used in chilled-water coils to provide air-

conditioning for buildings.](https://image.slidesharecdn.com/otecoe2023-230323123217-d637200d/85/OTEC_OE_2023-pptx-14-320.jpg)

![Refrigeration and Air-Conditioning

• The cold [5°C (41ºF)] seawater made available

by an OTEC system creates an opportunity to

provide large amounts of cooling to operations

that are related to or close to the plant.

• The cold seawater delivered to an OTEC plant

can be used in chilled-water coils to provide air-

conditioning for buildings.](https://image.slidesharecdn.com/otecoe2023-230323123217-d637200d/85/OTEC_OE_2023-pptx-21-320.jpg)