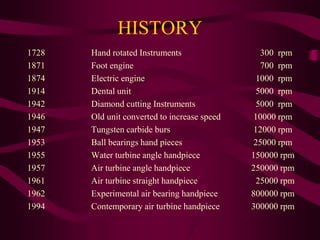

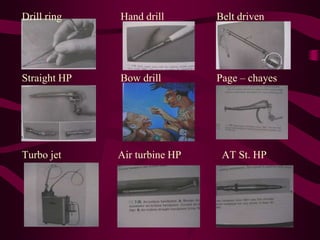

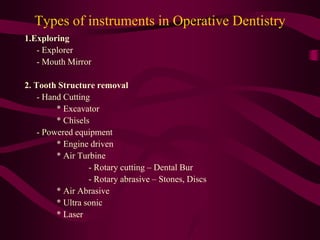

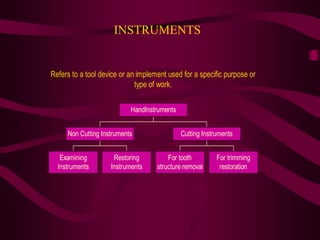

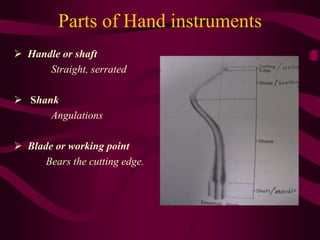

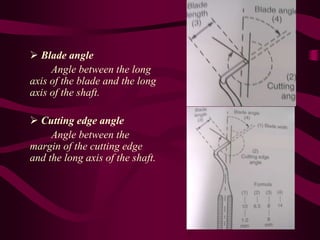

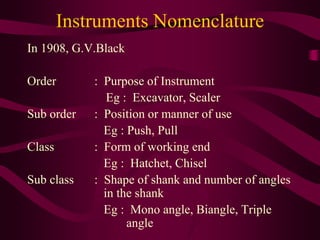

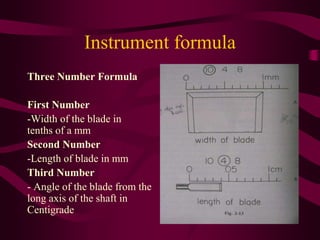

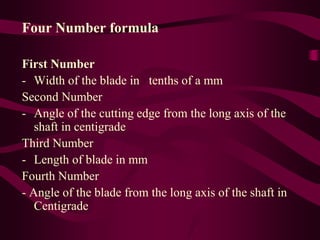

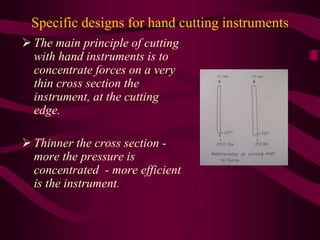

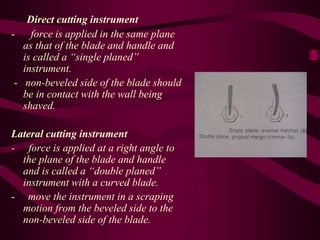

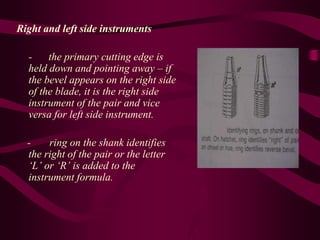

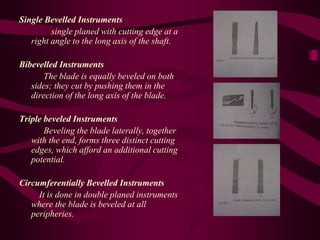

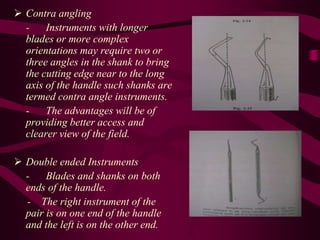

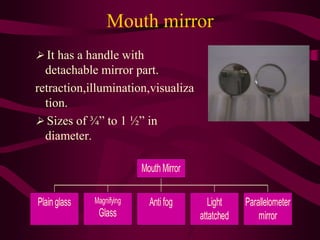

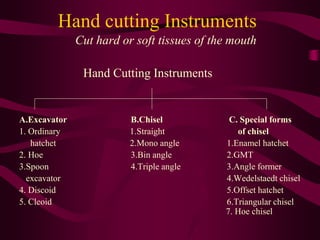

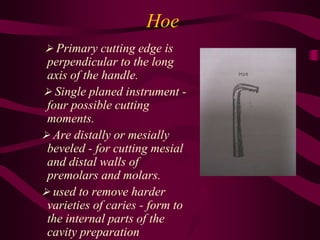

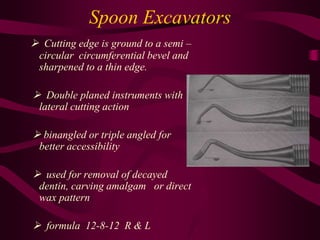

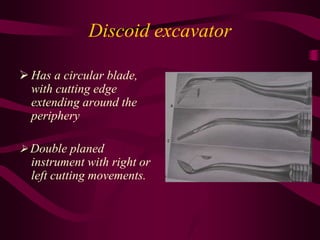

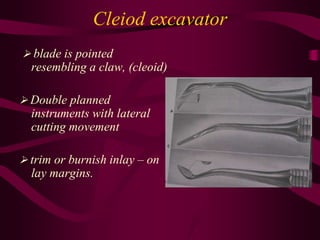

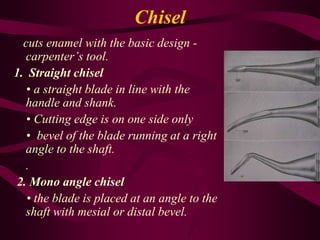

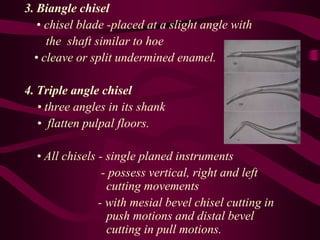

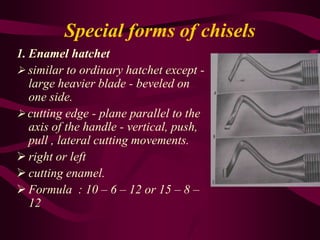

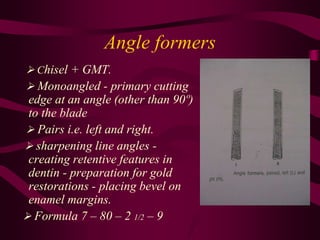

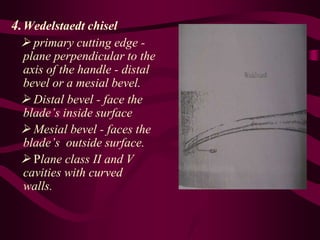

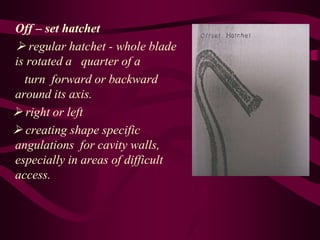

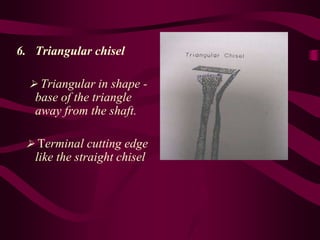

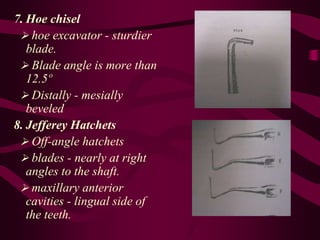

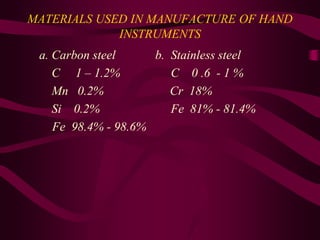

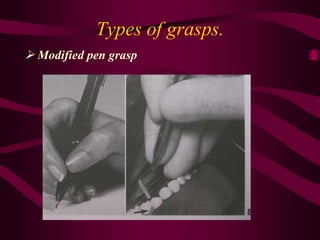

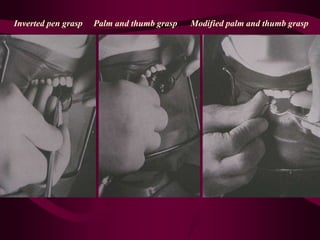

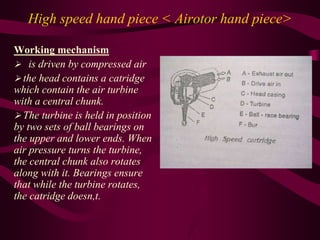

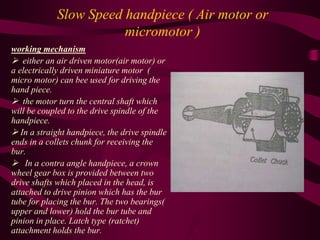

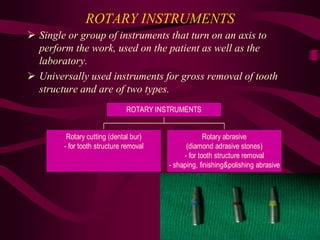

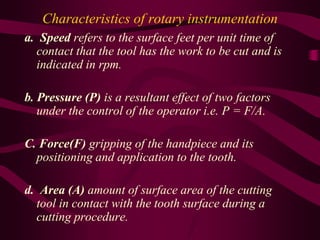

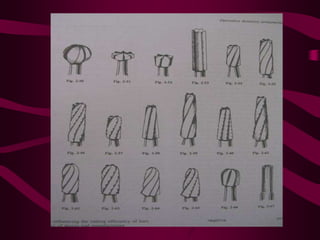

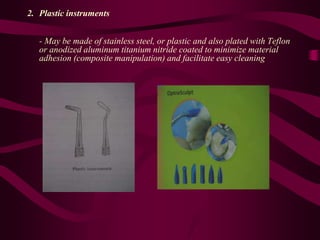

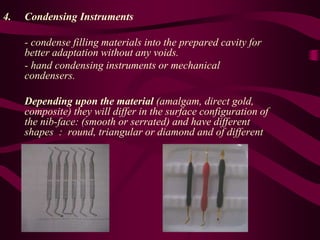

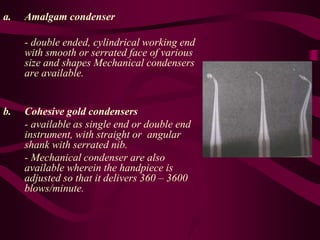

This document provides an overview of operative instruments used in dentistry. It discusses the history of powered instruments and increasing rotational speeds over time. It then classifies and describes various hand cutting instruments like excavators, chisels and their designs. It also covers powered cutting equipment like air turbines and electric engines. It discusses the materials, sharpening and proper grasp for hand instruments. Finally, it outlines criteria for evaluating high speed dental handpieces.