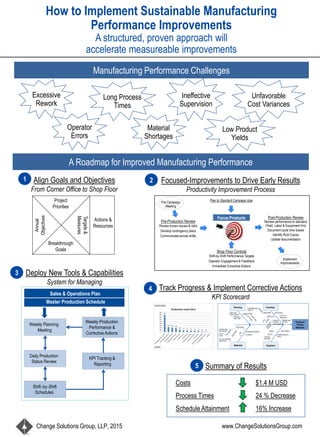

This document provides a roadmap for improving manufacturing performance through a structured approach. It begins with aligning goals and objectives from senior leadership down to the shop floor. The next step is to focus on early, measurable improvements to drive results. This involves deploying new tools and capabilities as well as tracking progress and implementing corrective actions. Key steps include pre-production reviews to plan for issues, setting shift-by-shift performance targets, taking immediate corrective actions, and conducting post-production reviews to identify root causes and update documentation. The overall goal is to decrease process times, increase schedule attainment, and reduce costs.