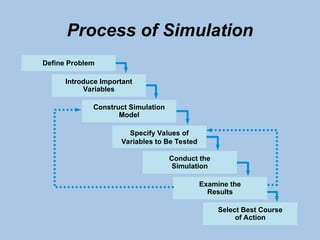

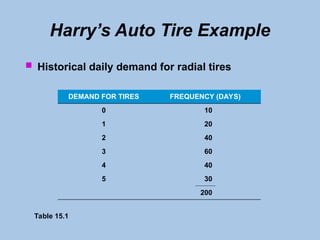

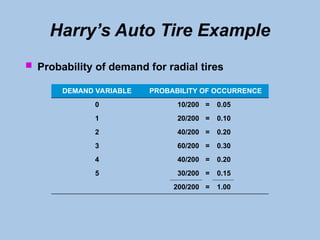

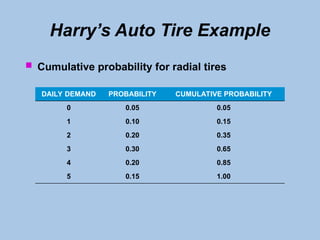

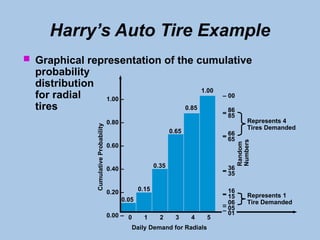

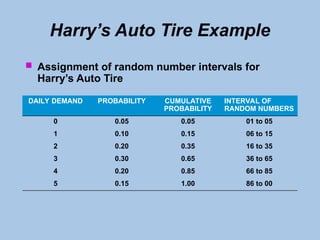

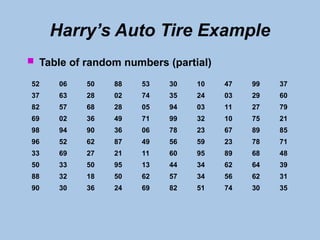

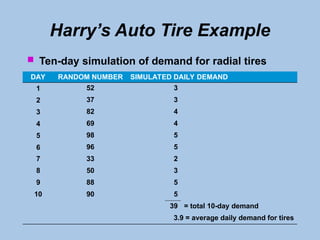

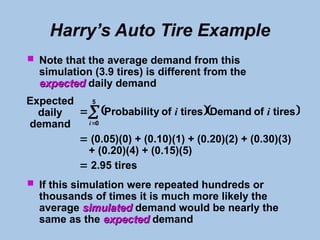

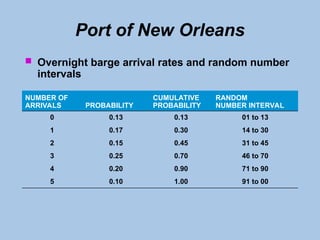

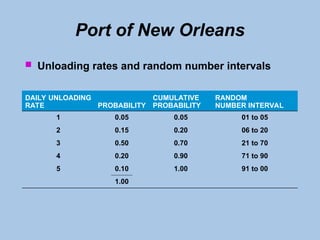

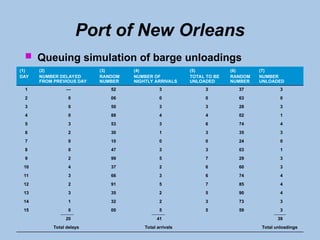

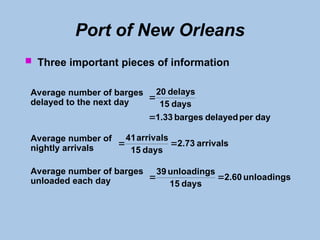

The document outlines the principles and processes of simulation modeling, focusing on its utility in analyzing complex real-world problems through a mathematical approach. It covers the seven steps of conducting a simulation, discusses advantages and disadvantages, and introduces the Monte Carlo method for handling probabilistic elements. Additionally, it presents practical examples, such as managing inventory at Harry's Auto Tire and simulating unloading operations at the Port of New Orleans.