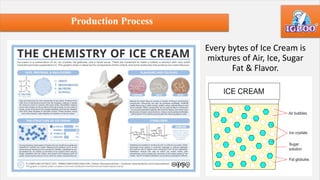

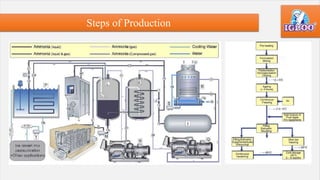

The document outlines the operations and production processes of Igloo Ice Cream, a brand under Abdul Monem Limited, highlighting its history, production capacity, and quality control measures. It discusses various ingredients, machinery used in production, and challenges faced in the market, including power supply issues and competition. Additionally, it emphasizes the importance of research and development to meet consumer demands and enhance brand value.