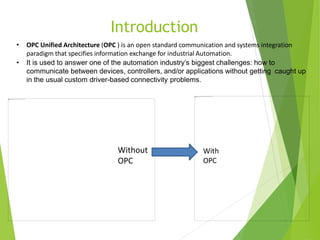

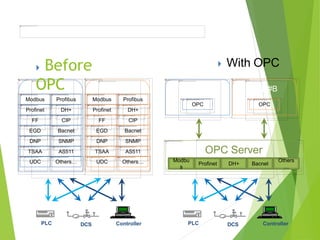

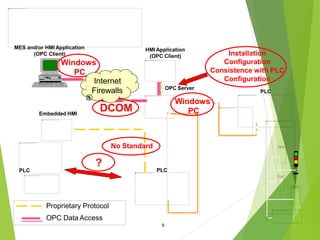

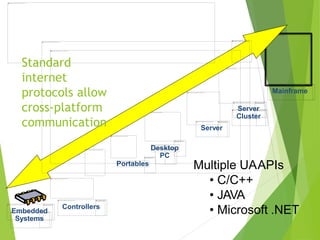

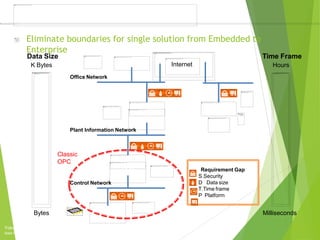

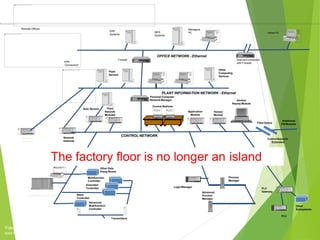

OPC (OLE for Process Control) is an open standard for industrial device connectivity that allows different industrial systems and applications to communicate by providing a common interface. OPC Unified Architecture (OPC UA) is the next generation of OPC that uses internet standards like web services to enable secure and reliable communication across networks and platforms. OPC UA defines an information model and services that allow OPC clients to access process data from OPC servers connected to industrial devices without needing to understand the native protocols of each device.