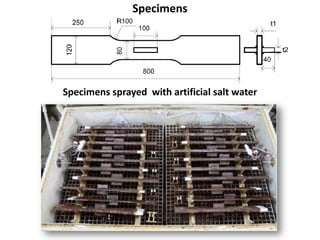

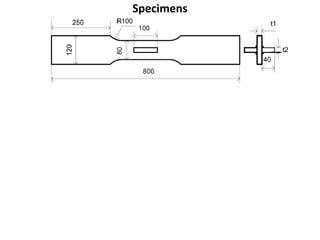

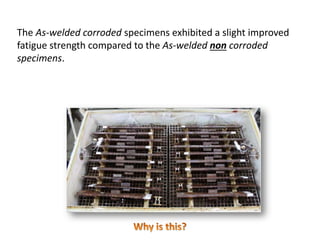

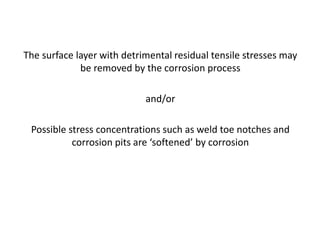

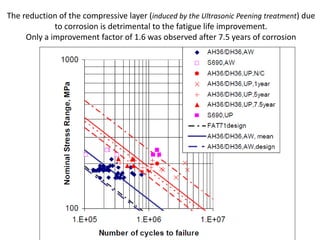

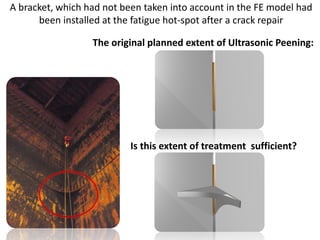

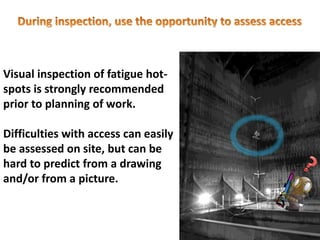

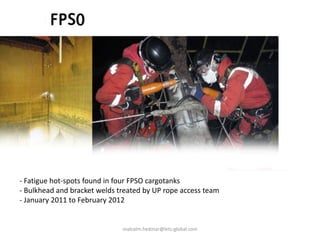

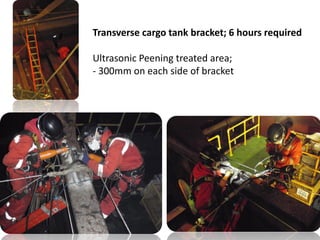

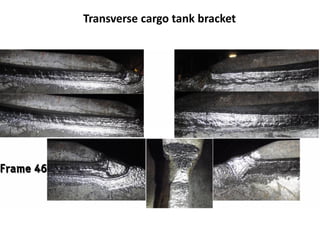

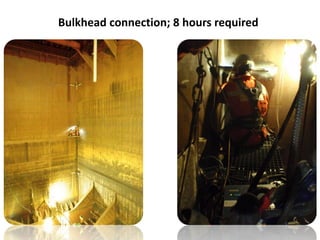

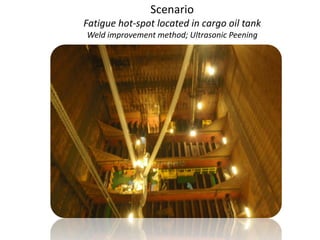

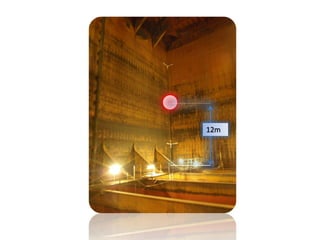

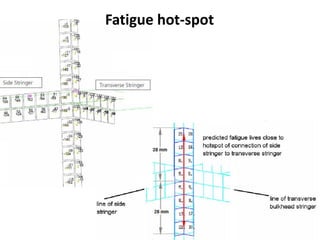

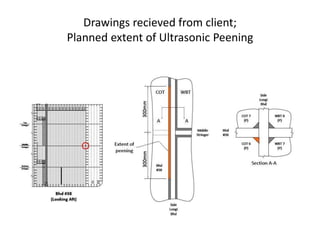

The document discusses the effects of artificial saltwater corrosion on as-welded specimens and highlights the importance of visual inspections for fatigue hot-spots prior to work planning. It emphasizes the significance of risk-based inspection (RBI) in asset integrity management, detailing its components and the necessary data for effective implementation. Additionally, the document outlines advantages and challenges related to ultrasonic peening as a method to improve fatigue hot-spots in various structural components.