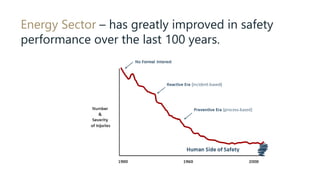

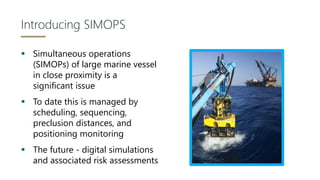

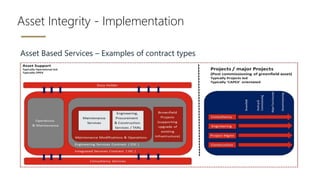

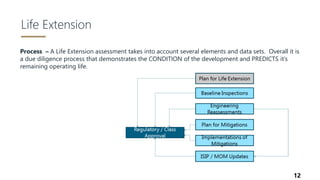

The document discusses advancements in safety performance and asset integrity in the deepwater energy sector, emphasizing that achieving zero incidents requires a commitment to safe engineering and operational protocols. It highlights the importance of integrating digital technologies for risk assessment and management, while addressing challenges such as inconsistent operational data and the need for innovative asset management solutions. The future vision includes creating a digital ecosystem to enhance real-time decision-making and operational performance.