Embed presentation

Downloaded 12 times

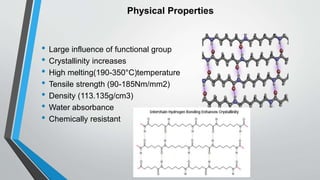

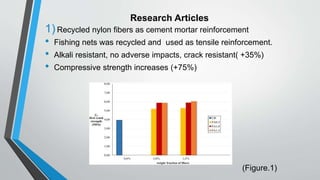

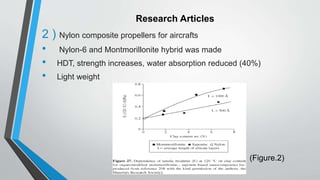

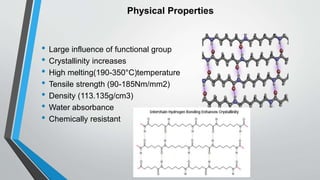

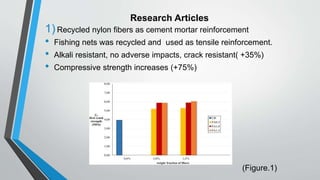

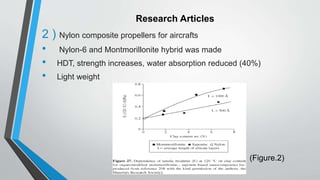

This document summarizes key information about the synthetic polymer nylon. It discusses nylon's origins at DuPont Company and its production via condensation polymerization of diamines and diacarboxylic acids. The document outlines different nylon types (6.6, 6, 6.7, etc.) and provides details on nylon's physical properties like high melting temperatures, tensile strength, density, and water absorbance. Processing techniques like injection molding are mentioned along with common nylon applications in textiles, automotive, and furniture. Finally, the document summarizes two research articles about using recycled nylon fibers to reinforce cement and creating nylon-composite propellers for aircraft.