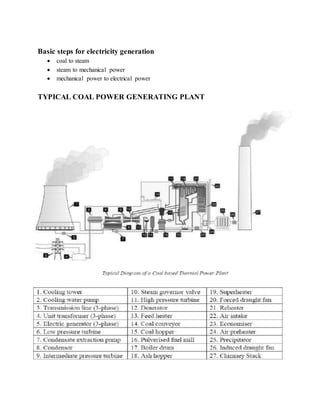

The document provides information about the author's 4 week training at NTPC from June to July 2016. They visited the Boiler Maintenance Department and Turbine Maintenance Department to learn how electricity is produced. NTPC is India's largest power company, generating over 45,000 MW of electricity using steam turbines powered by coal. The company was founded in 1975 and uses the Rankine cycle to convert heat from coal into mechanical power and then electrical power.