(1) The document discusses nonlinear modeling of reinforced concrete frame structures. It focuses on concentrated plasticity approaches where plasticity is concentrated at specific points, typically at the ends of beams and columns.

(2) Two methods for defining plastic hinge behavior are described: distributed plasticity, where plasticity is spread over the element length, and concentrated plasticity, where it is localized at specific points. Concentrated plasticity is commonly used for nonlinear static analysis of frames.

(3) Procedures for developing moment-rotation relationships for plastic hinges based on moment-curvature analysis or empirical equations are presented. These relationships define the inelastic behavior of components in the nonlinear analysis.

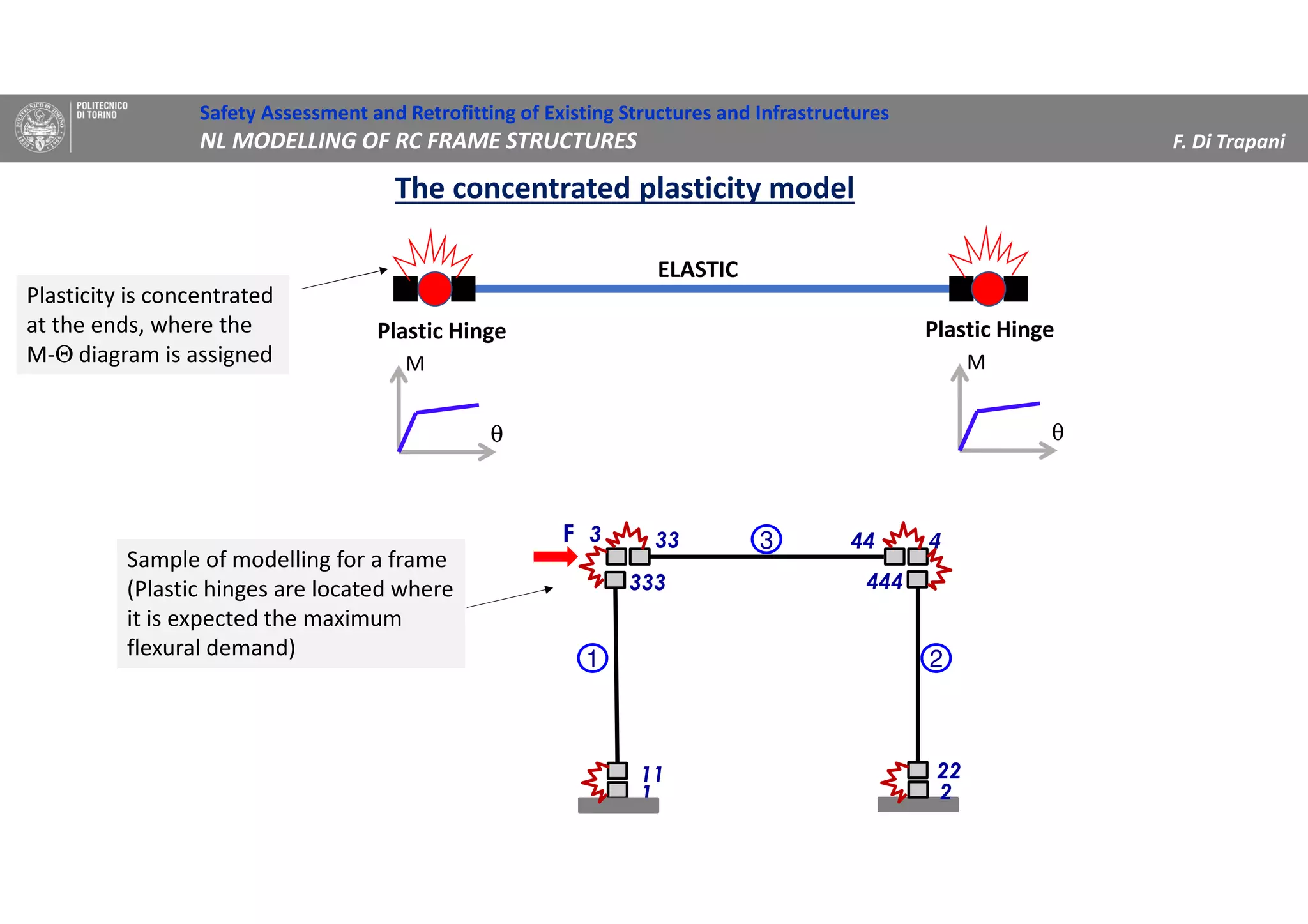

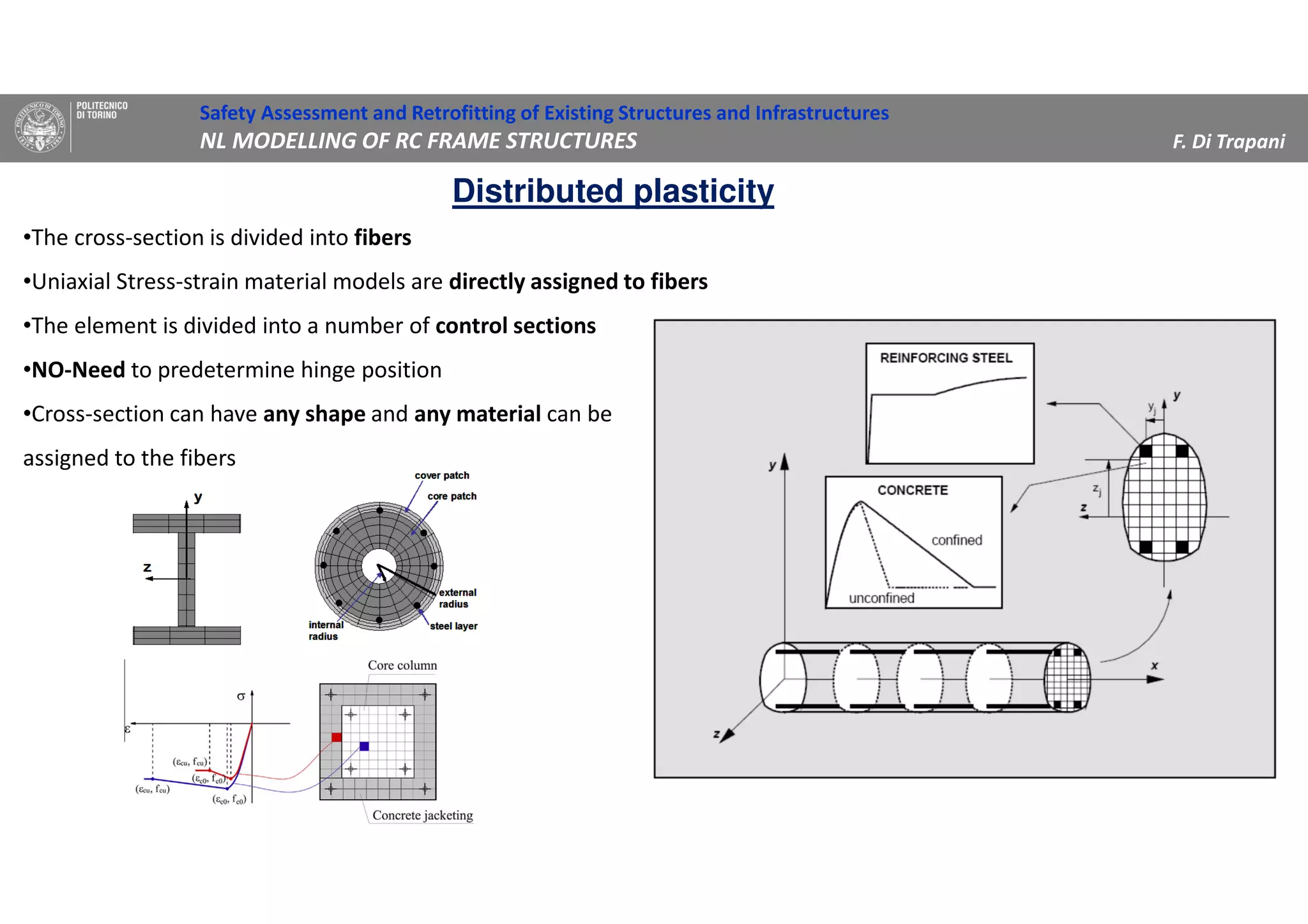

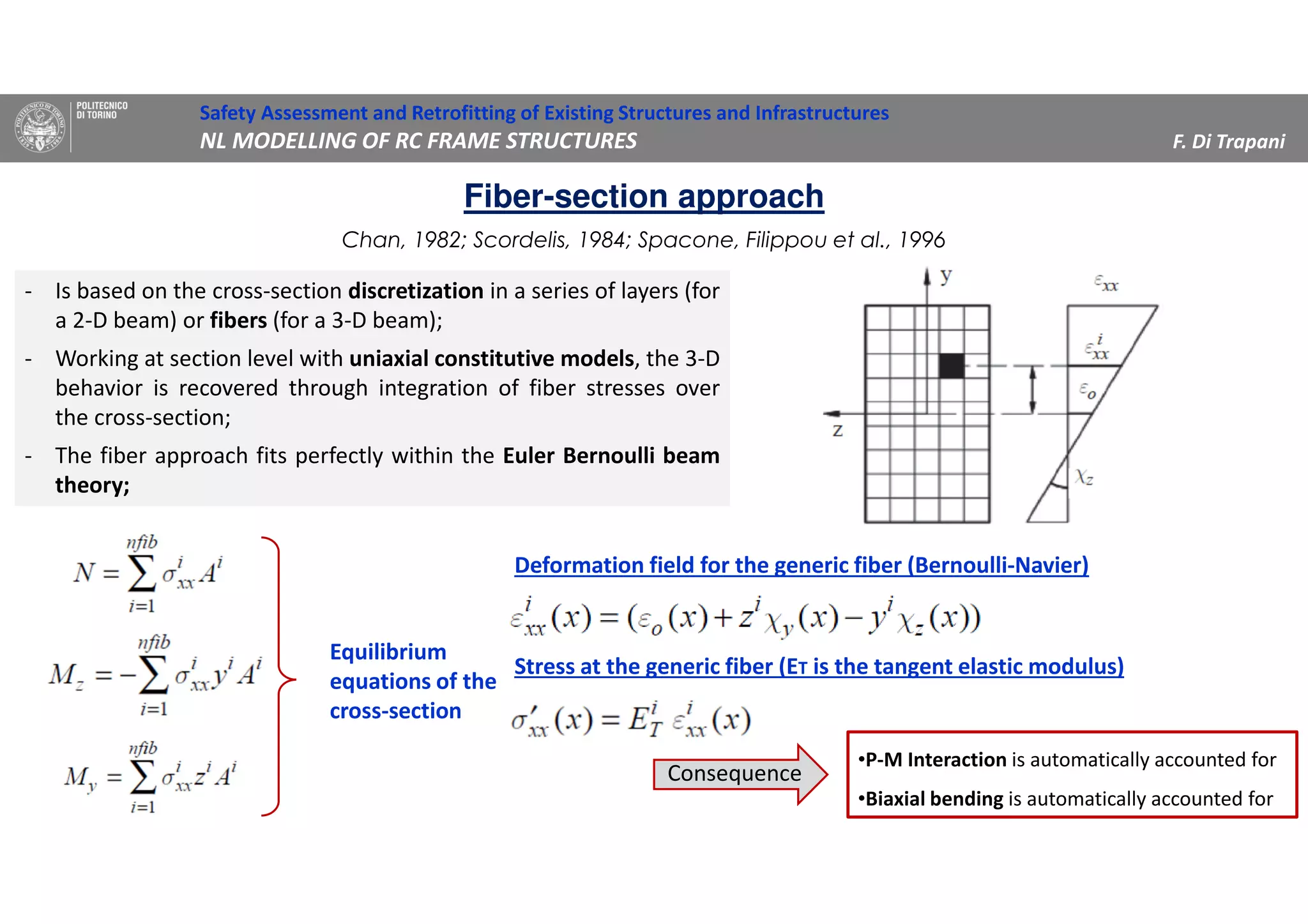

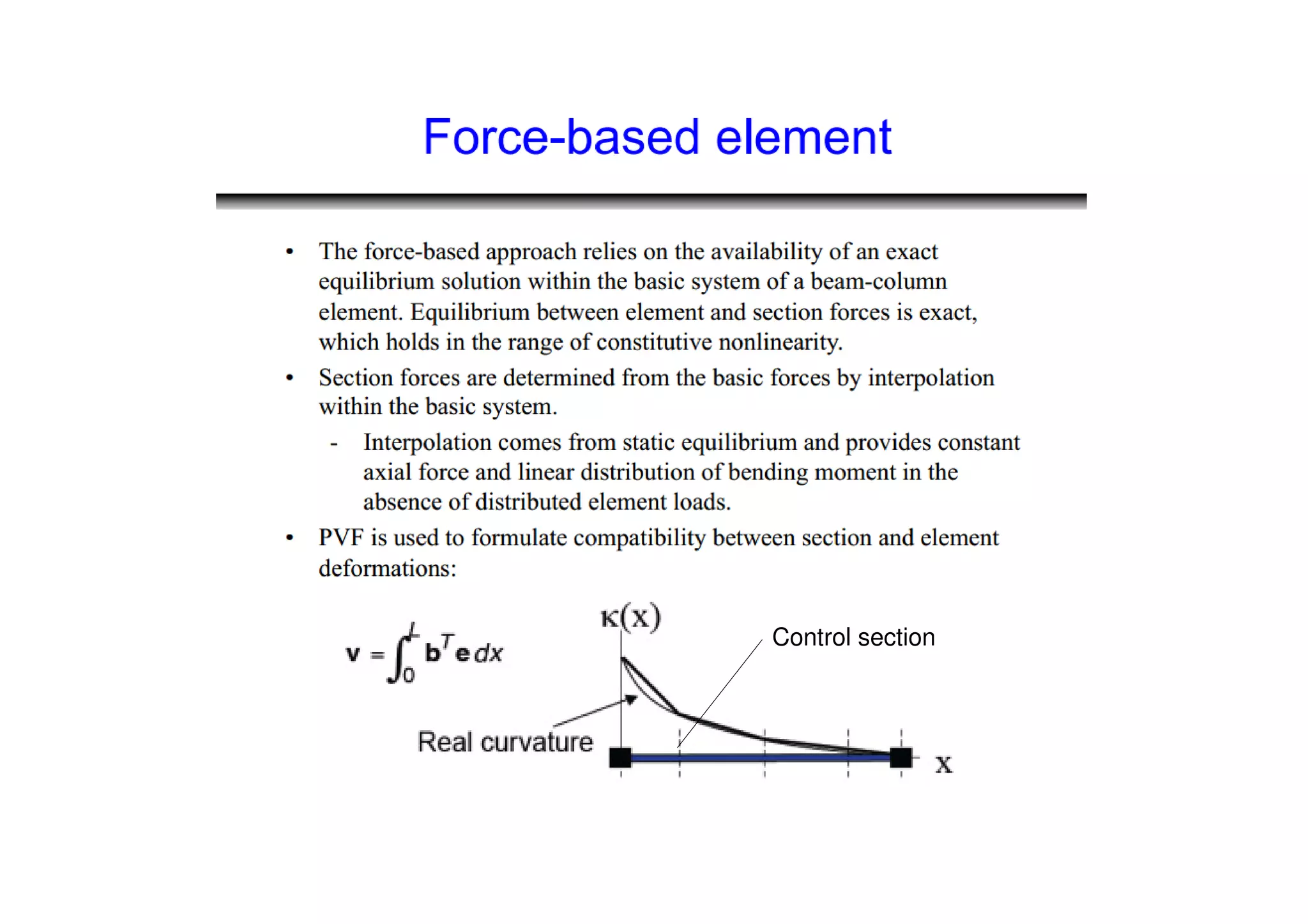

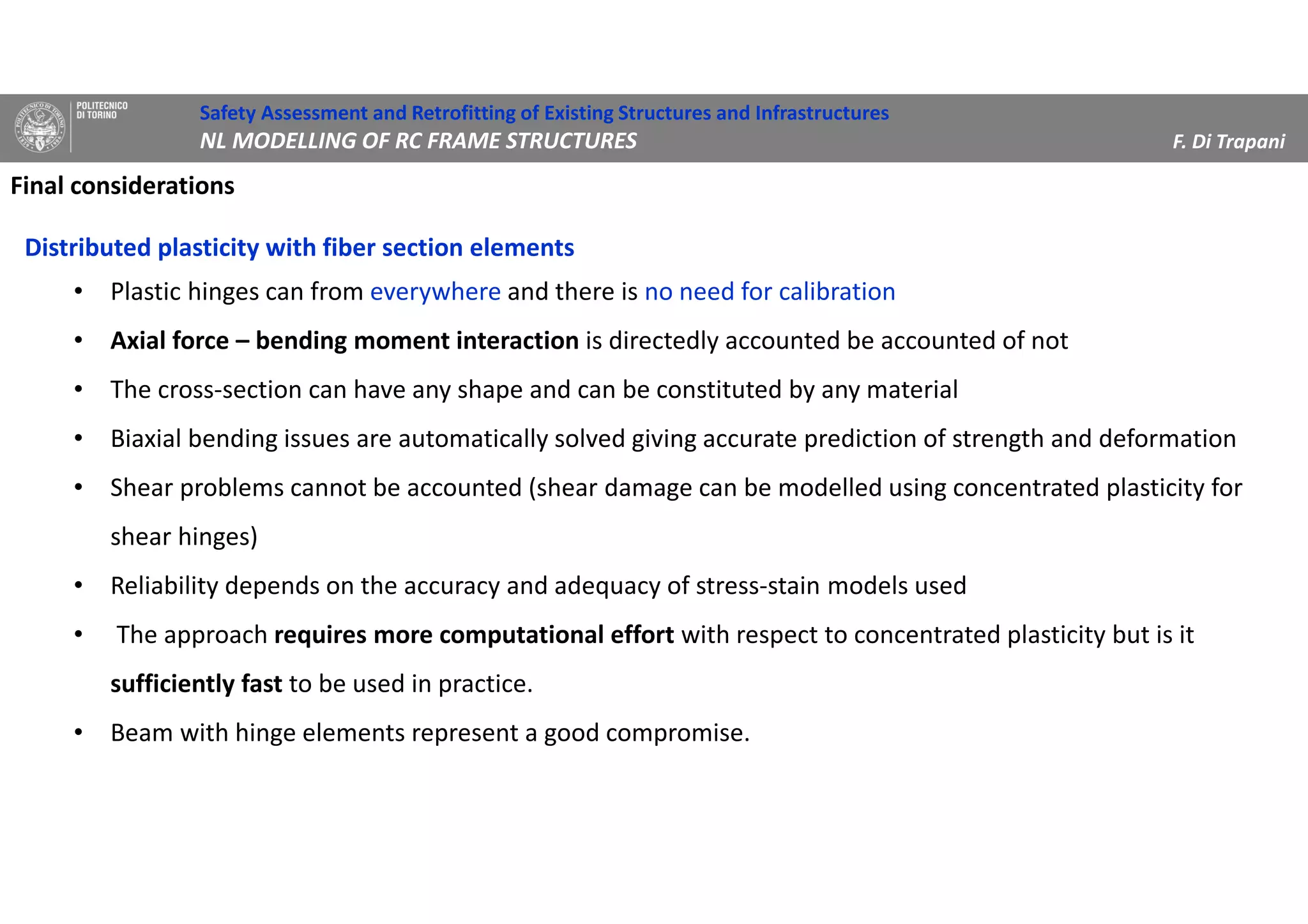

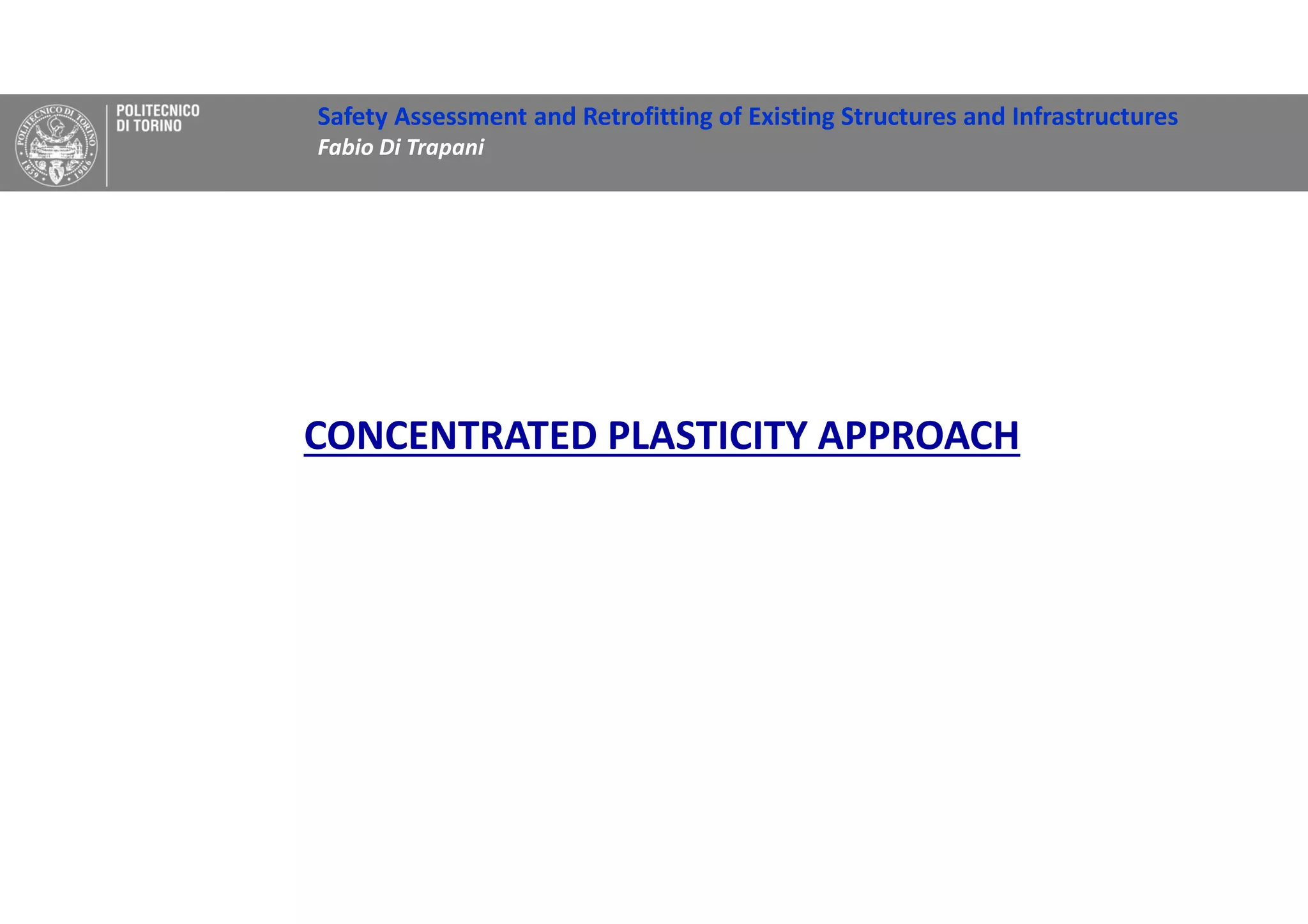

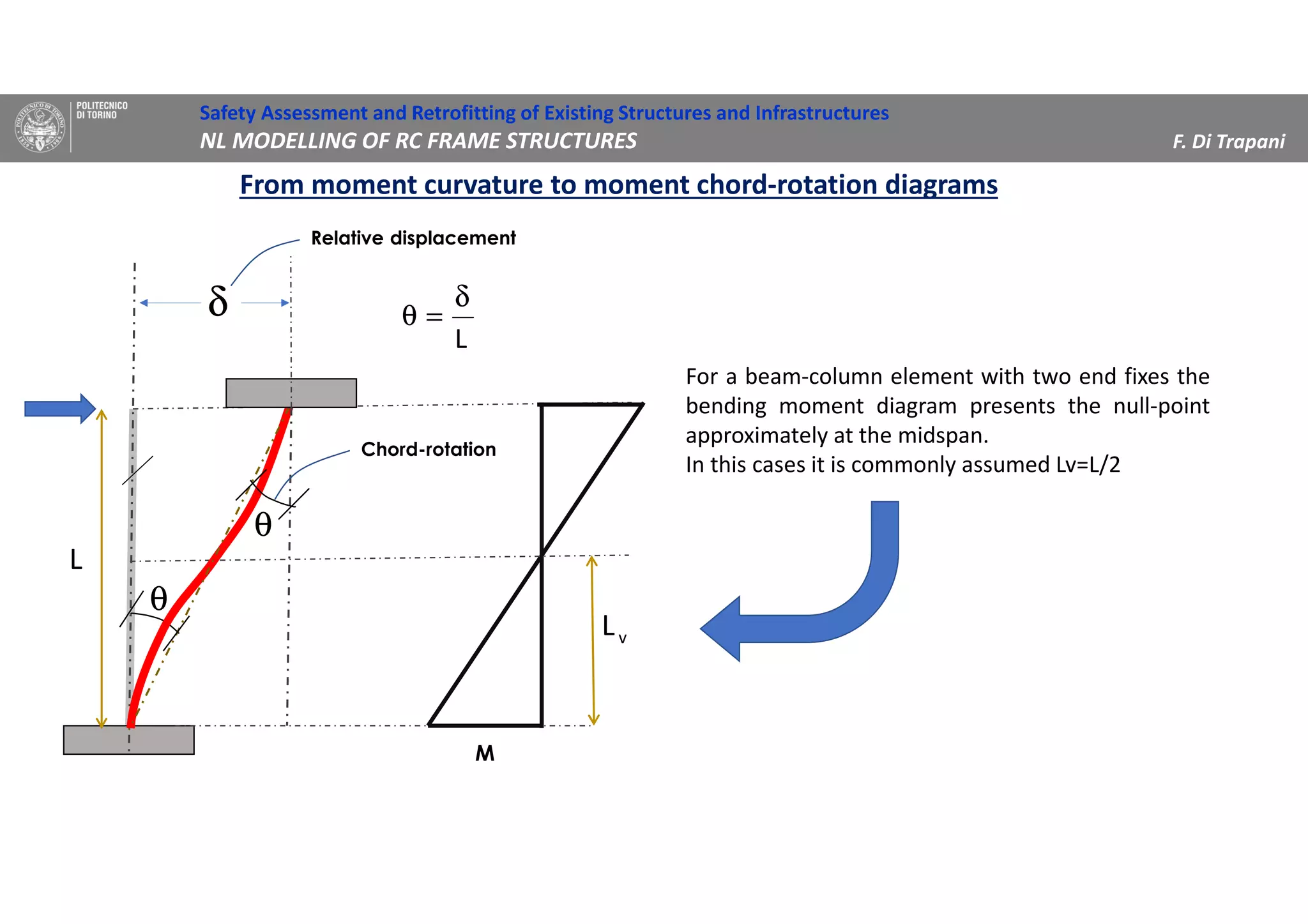

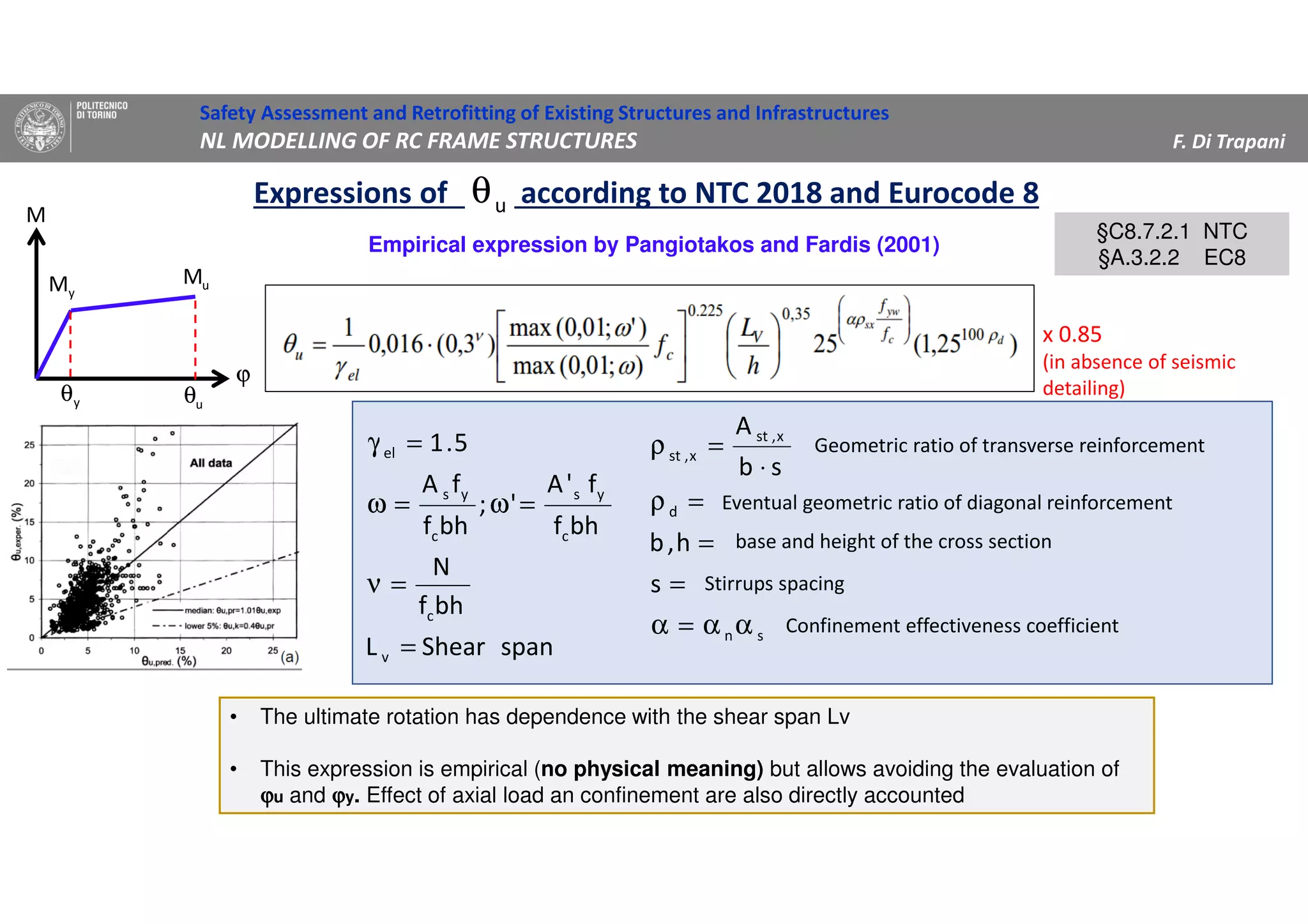

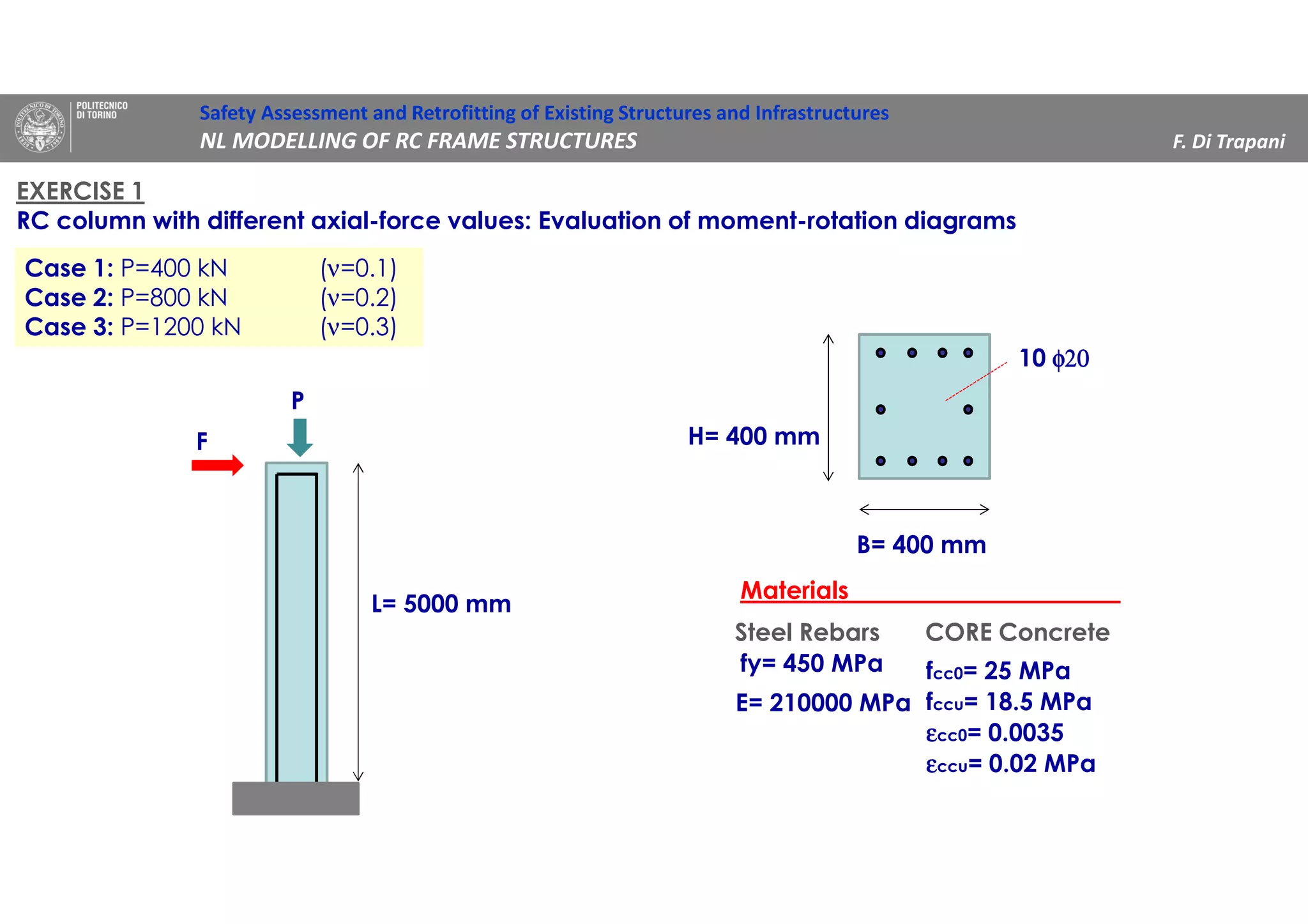

![EXERCISE 1

Moment – curvature analysis of the cross-section

Case 1: P=400 kN (ν=0.1)

Case 2: P=800 kN (ν=0.2)

Case 3: P=1600 kN(ν=0.4)

0

50

100

150

200

250

300

350

400

0 0,00005 0,0001 0,00015 0,0002 0,00025

M[kNm]

φφφφ [1/mm]

M-φφφφ diagrams

N=400 kN

N=800 kN

N=1200 kN

N=400 kN N=800 kN N=1200 kN

φφφφu [1/mm] 0.0002244 0.0001442 0.00011

φφφφy [1/mm] 0.0000099 0.0000111 0.00001237

My (ideal.) [kNm] 276.9 312 340

Ultimate curvature

Yielding curvature

Idealized yielding moment

Evaluate …

B= 400 mm

H= 400 mm

10 φ20φ20φ20φ20

Safety Assessment and Retrofitting of Existing Structures and Infrastructures

NL MODELLING OF RC FRAME STRUCTURES F. Di Trapani](https://image.slidesharecdn.com/5-200824114726/75/Nonlinear-modelling-of-RC-frame-structures-17-2048.jpg)

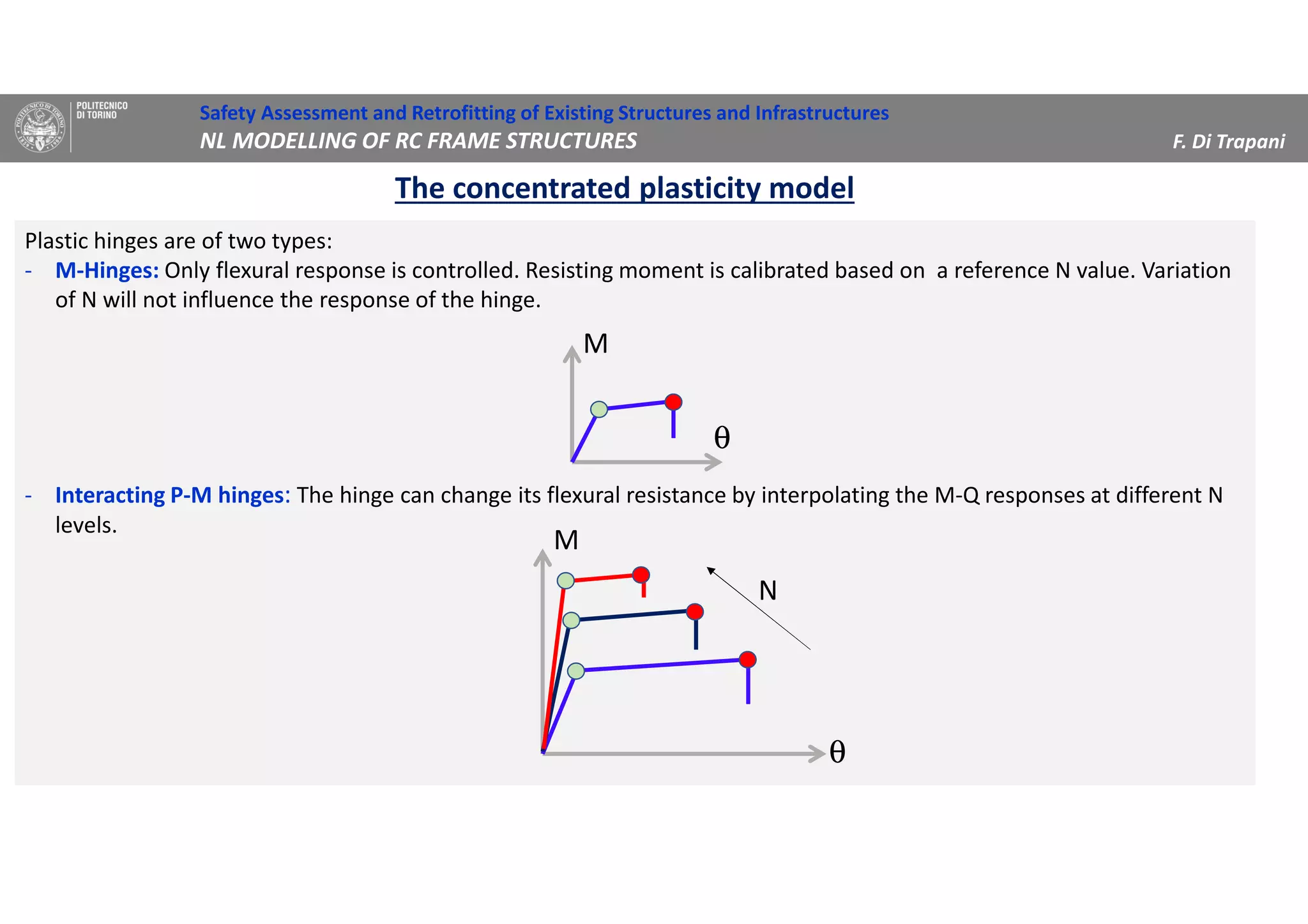

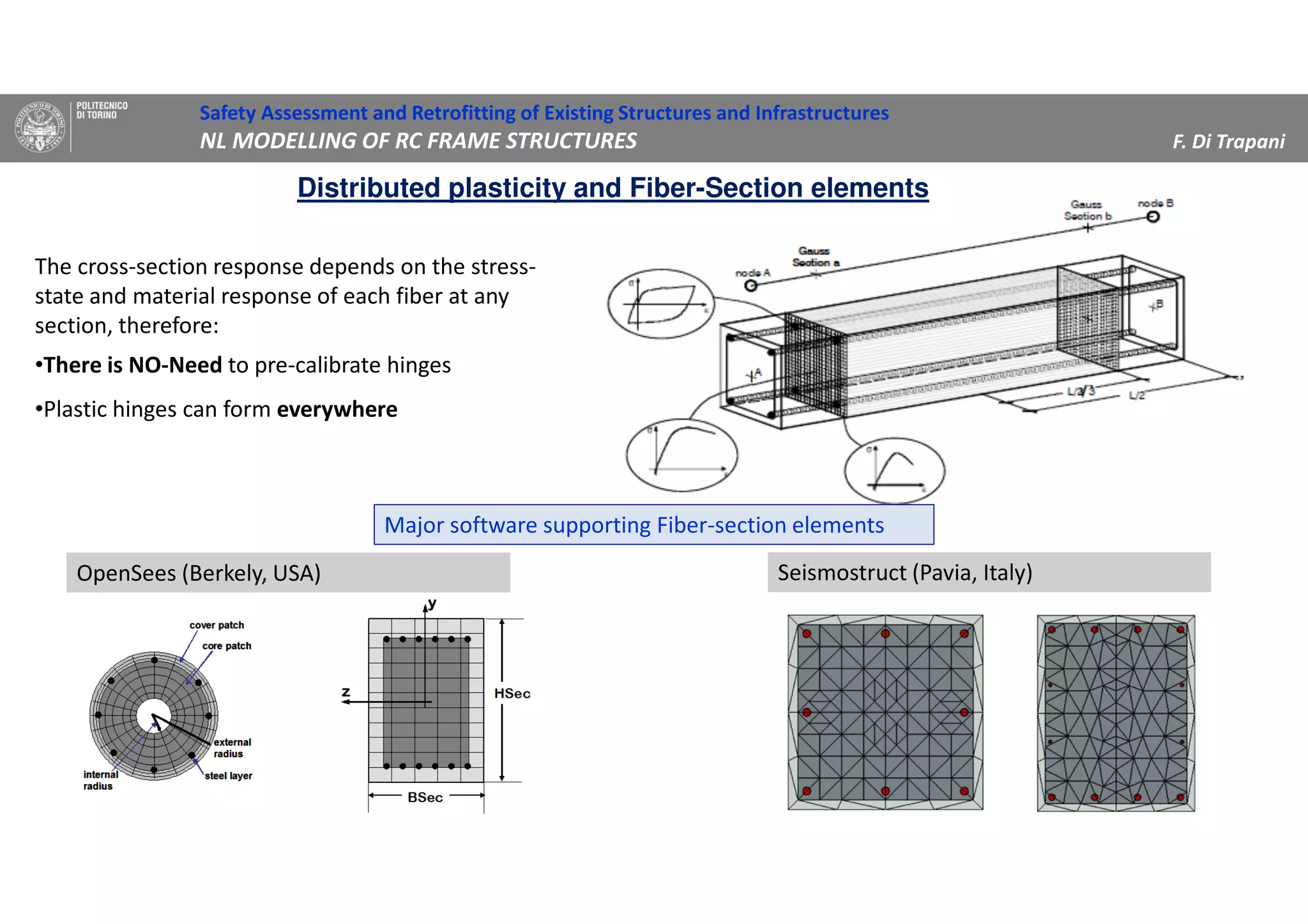

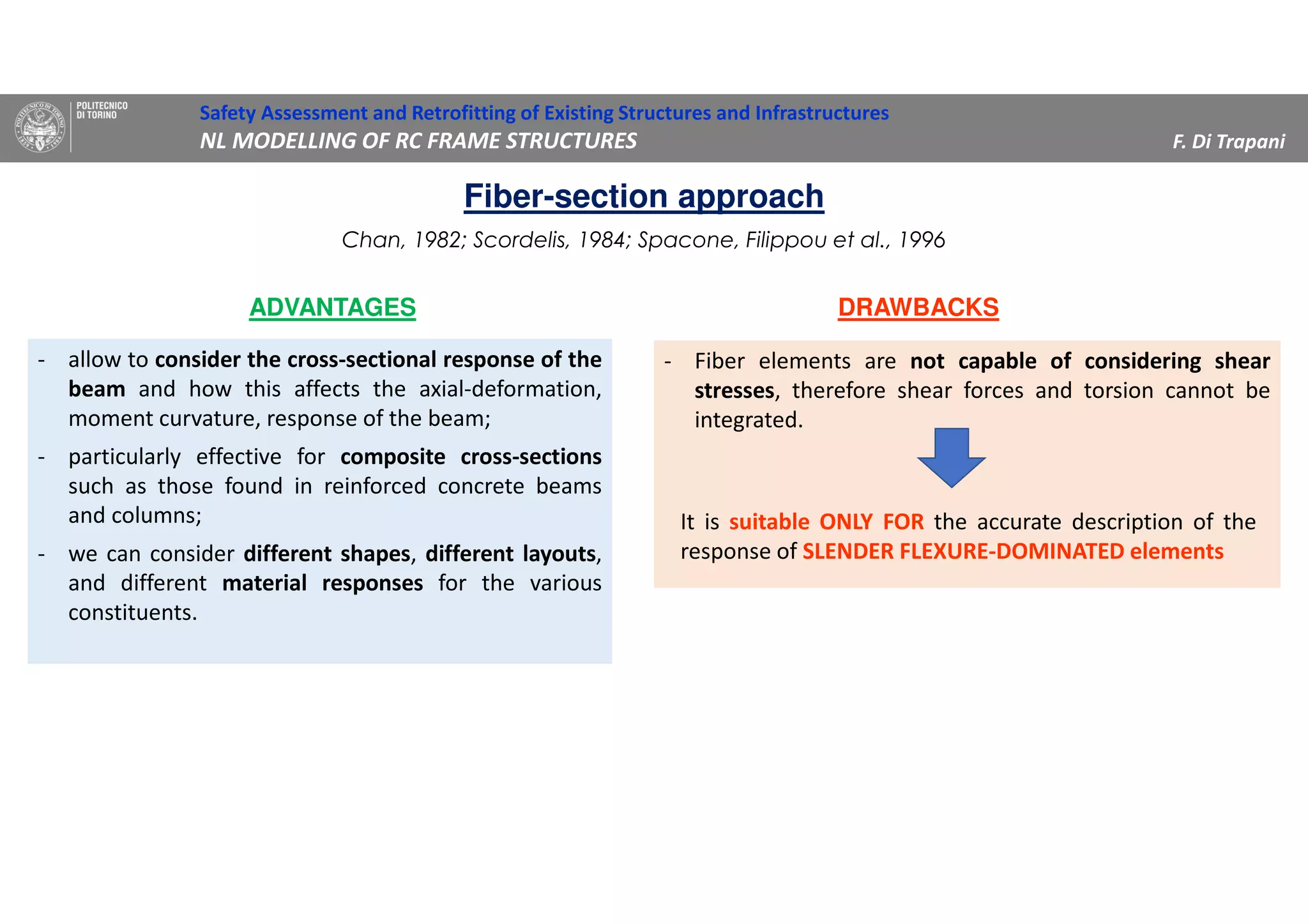

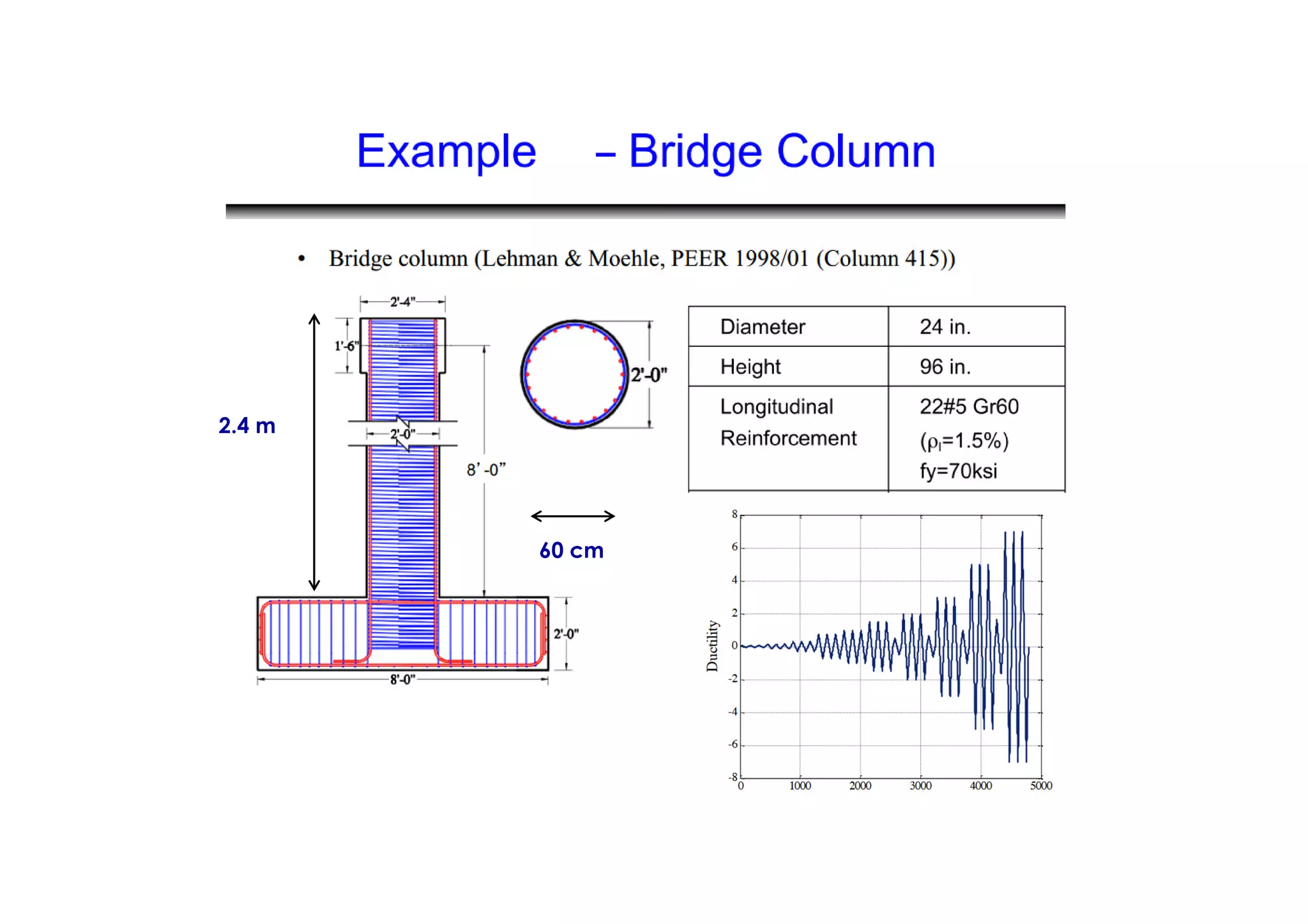

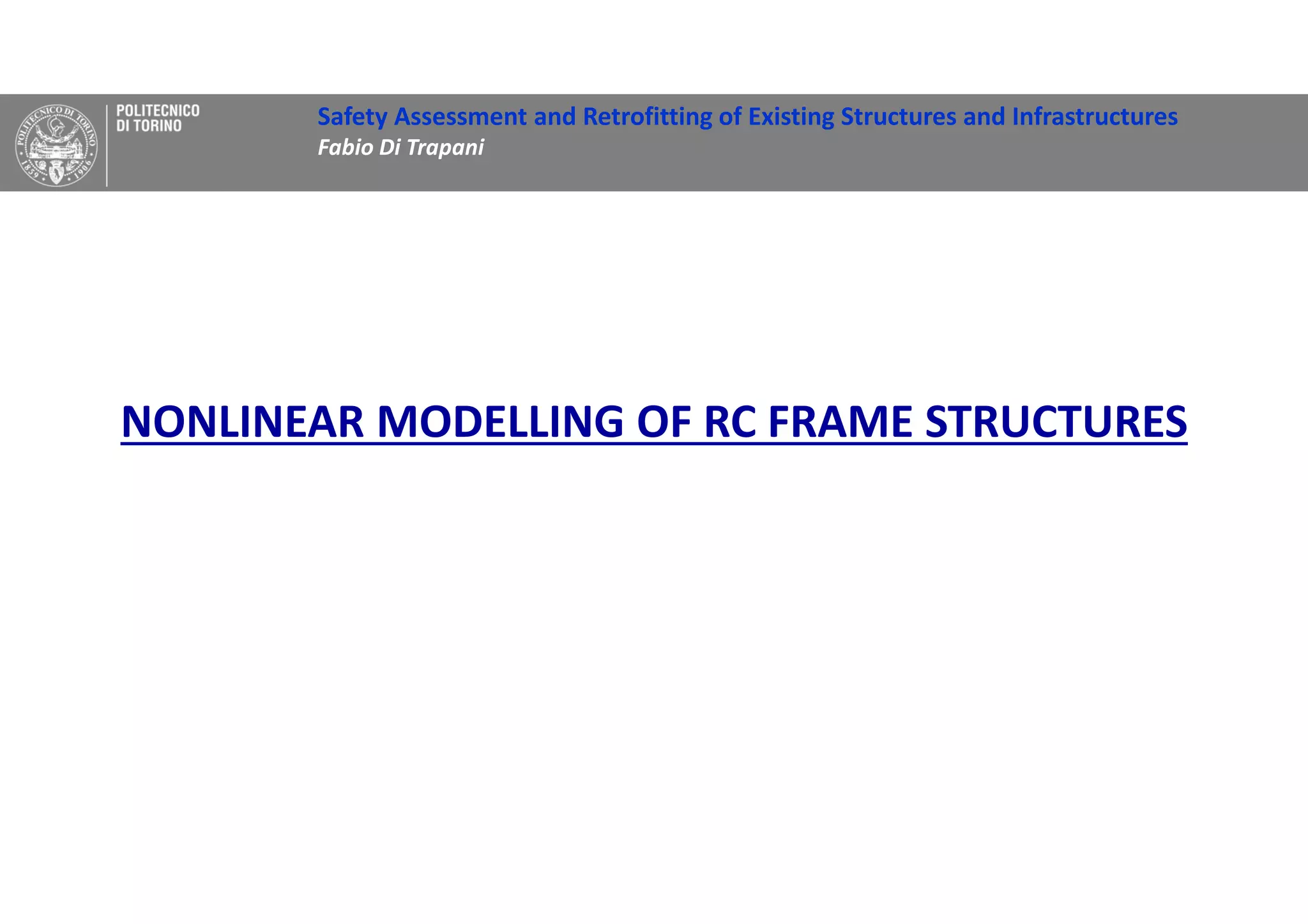

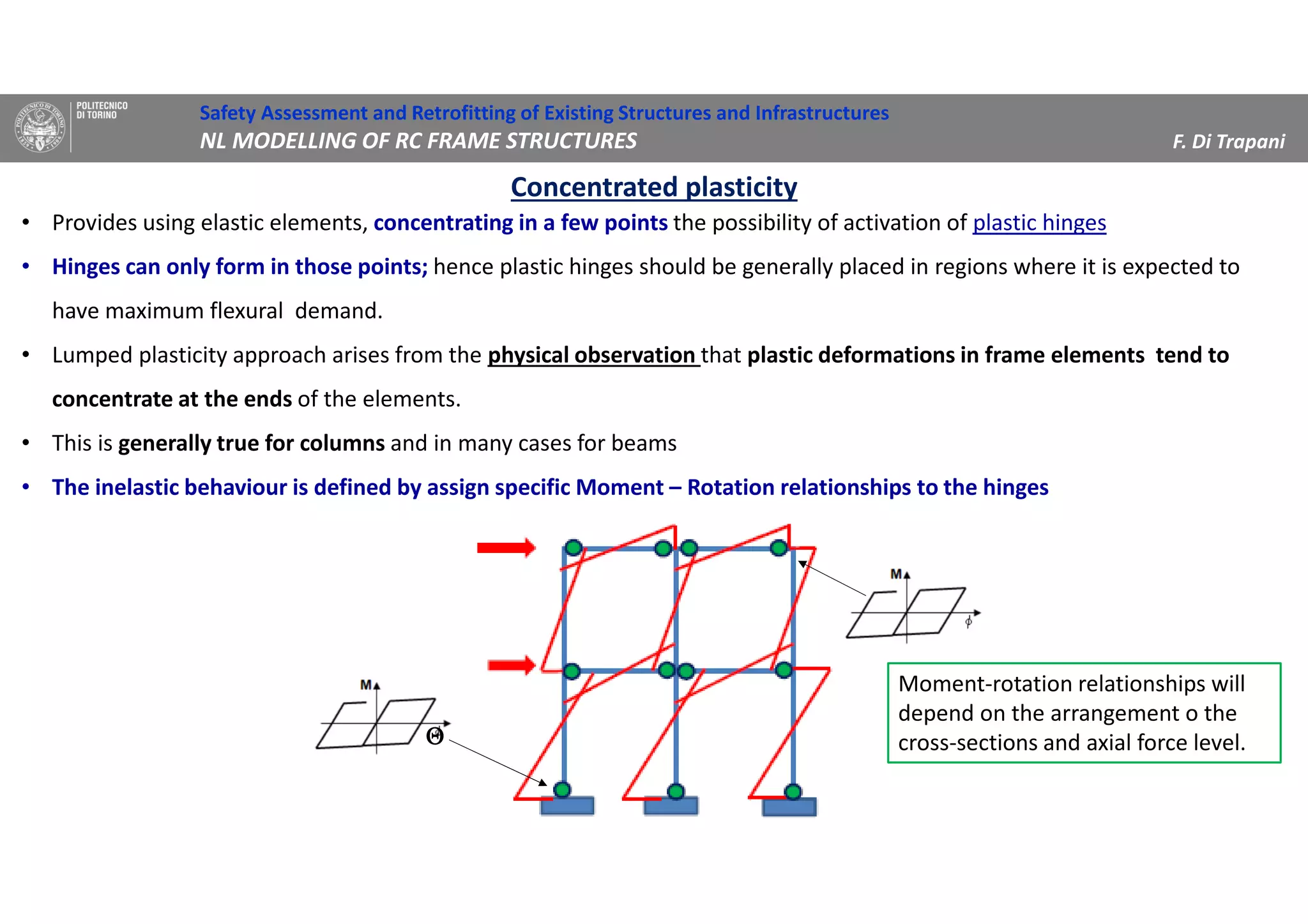

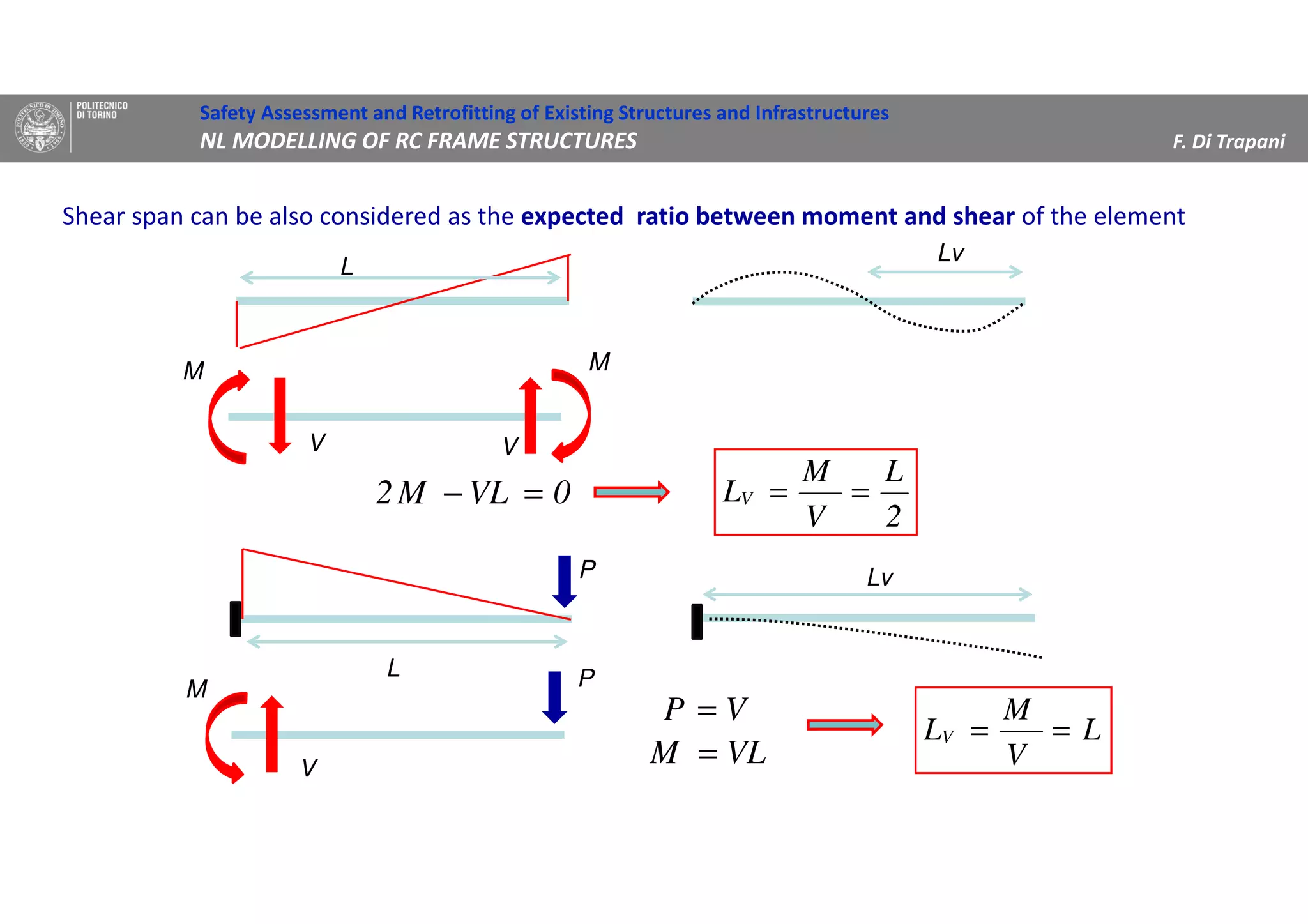

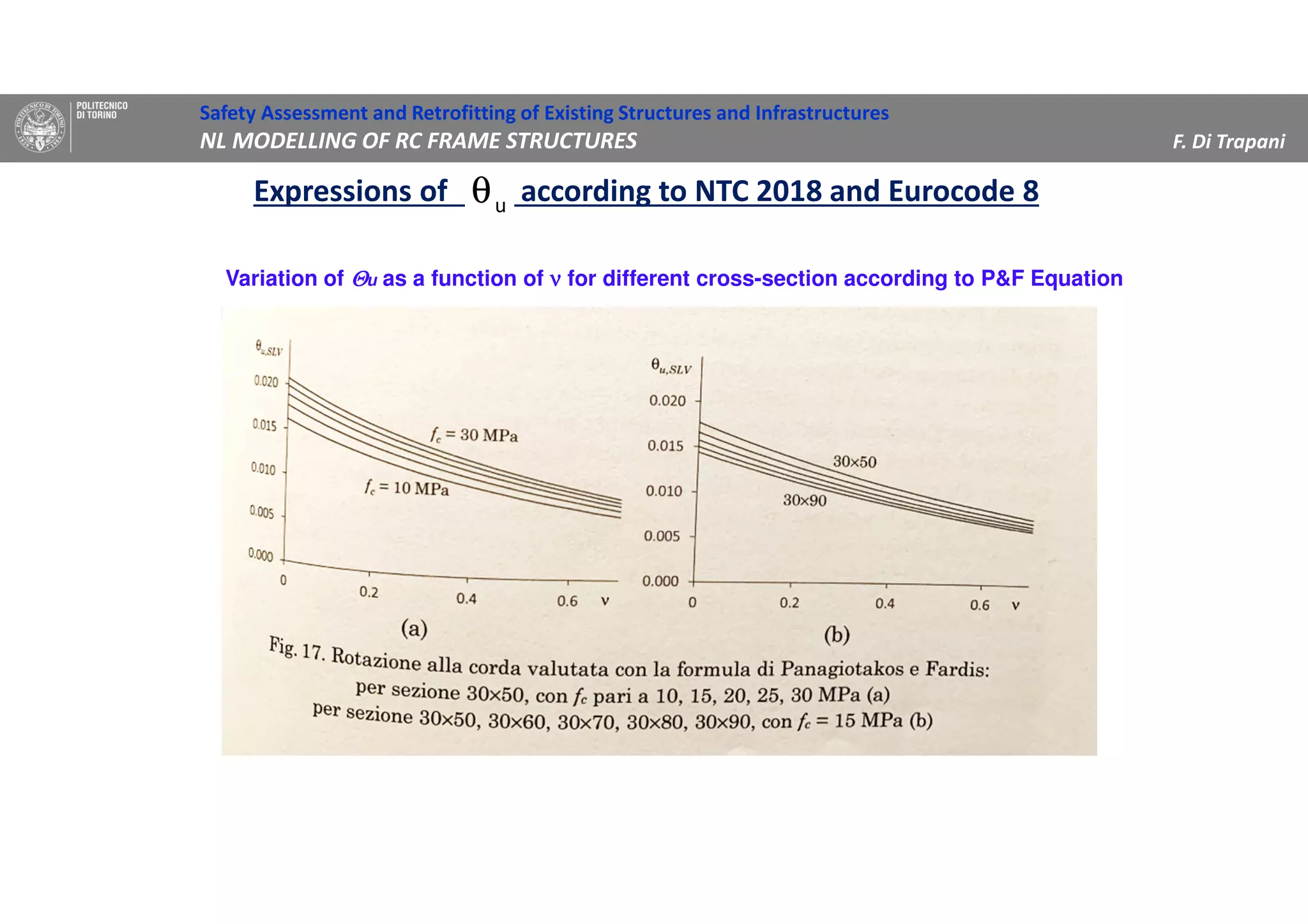

![EXERCISE 1

Evaluation of Moment – Rotation diagrams

Case 1: P=400 kN (ν=0.1)

Case 2: P=800 kN (ν=0.2)

Case 3: P=1600 kN(ν=0.4)

SECTION 400x400 Nu (kN) 4000

N v φφφφ u φφφφ y H B L L v fc dbl fy Lpl ΘΘΘΘ u ΘΘΘΘ y

(kN) - 1/mm 1/mm mm mm mm mm MPa mm MPa mm rad rad

400 0.10 0.00022 0.0000099 400 400 5000 5000 28 20 450 976.2 0.2091 0.0201

800 0.20 0.00014 0.00001111 400 400 5000 5000 28 20 450 976.2 0.1397 0.0224

1200 0.30 0.00011 0.00001237 400 400 5000 5000 28 20 450 976.2 0.1108 0.0248

0

50

100

150

200

250

300

350

0 0,05 0,1 0,15 0,2 0,25

M[kNm]

ΘΘΘΘ [rad]

M-ΘΘΘΘ diagrams

N=400 kN

N=800 kN

N=1200 kN

Safety Assessment and Retrofitting of Existing Structures and Infrastructures

NL MODELLING OF RC FRAME STRUCTURES F. Di Trapani](https://image.slidesharecdn.com/5-200824114726/75/Nonlinear-modelling-of-RC-frame-structures-18-2048.jpg)

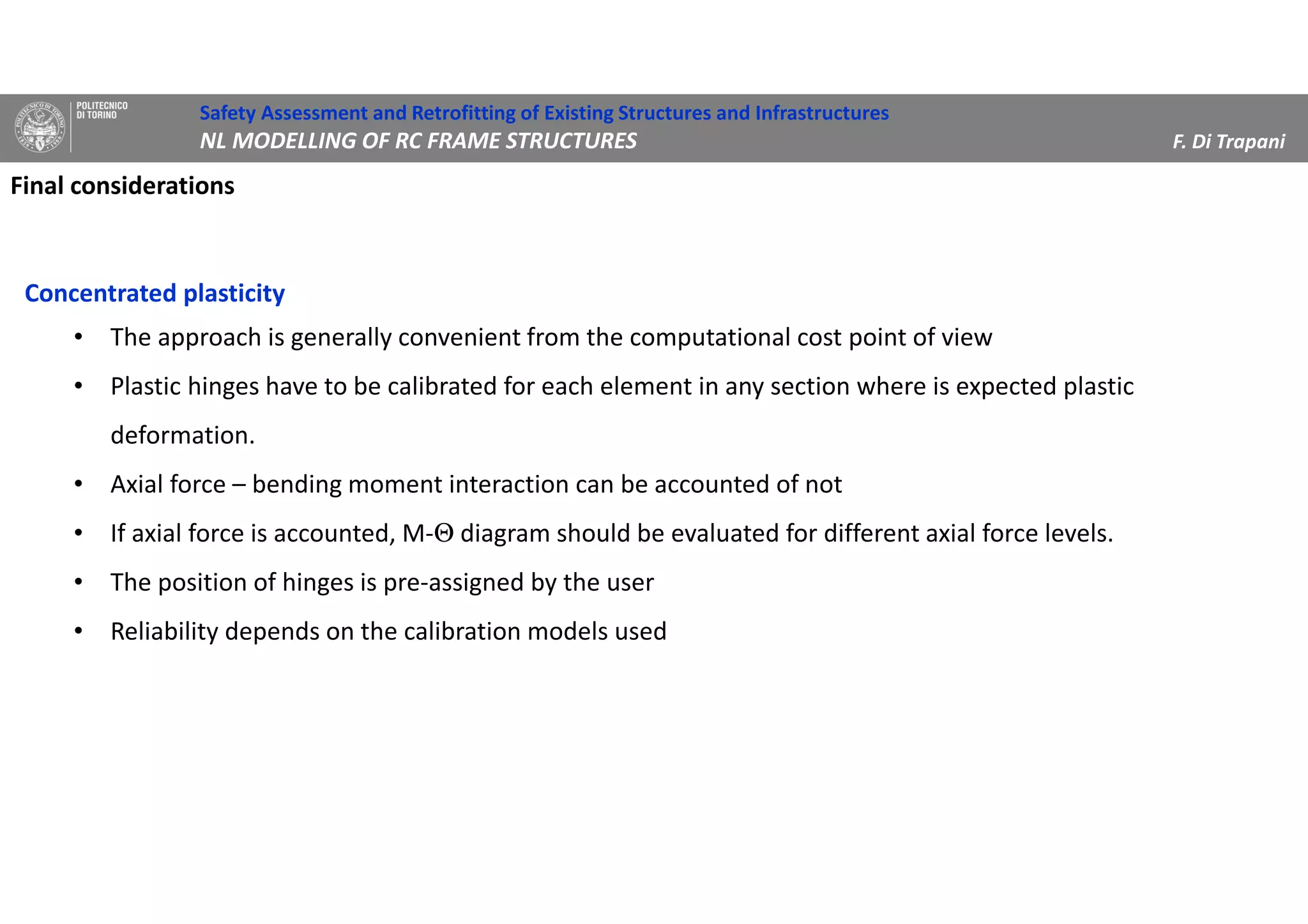

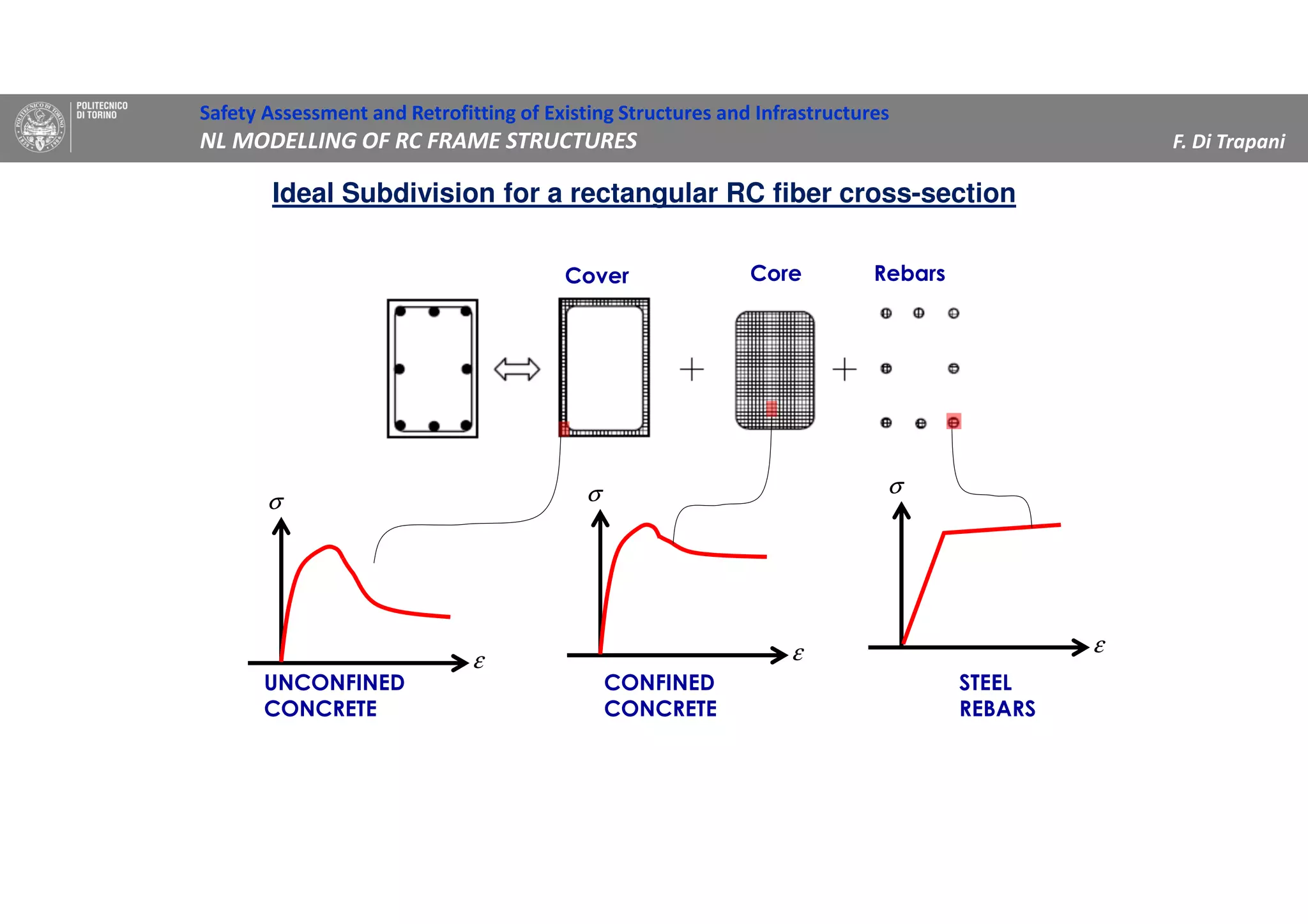

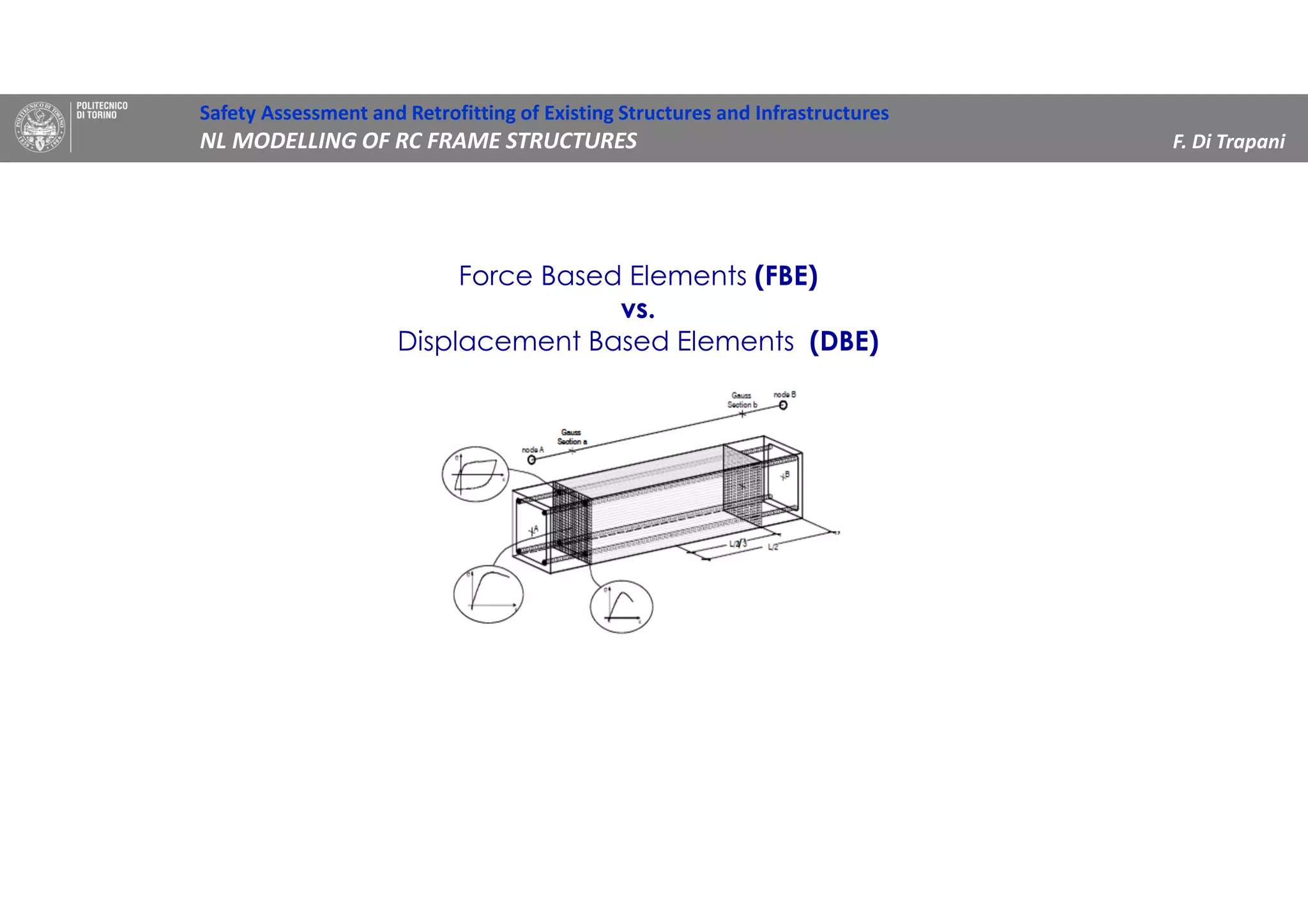

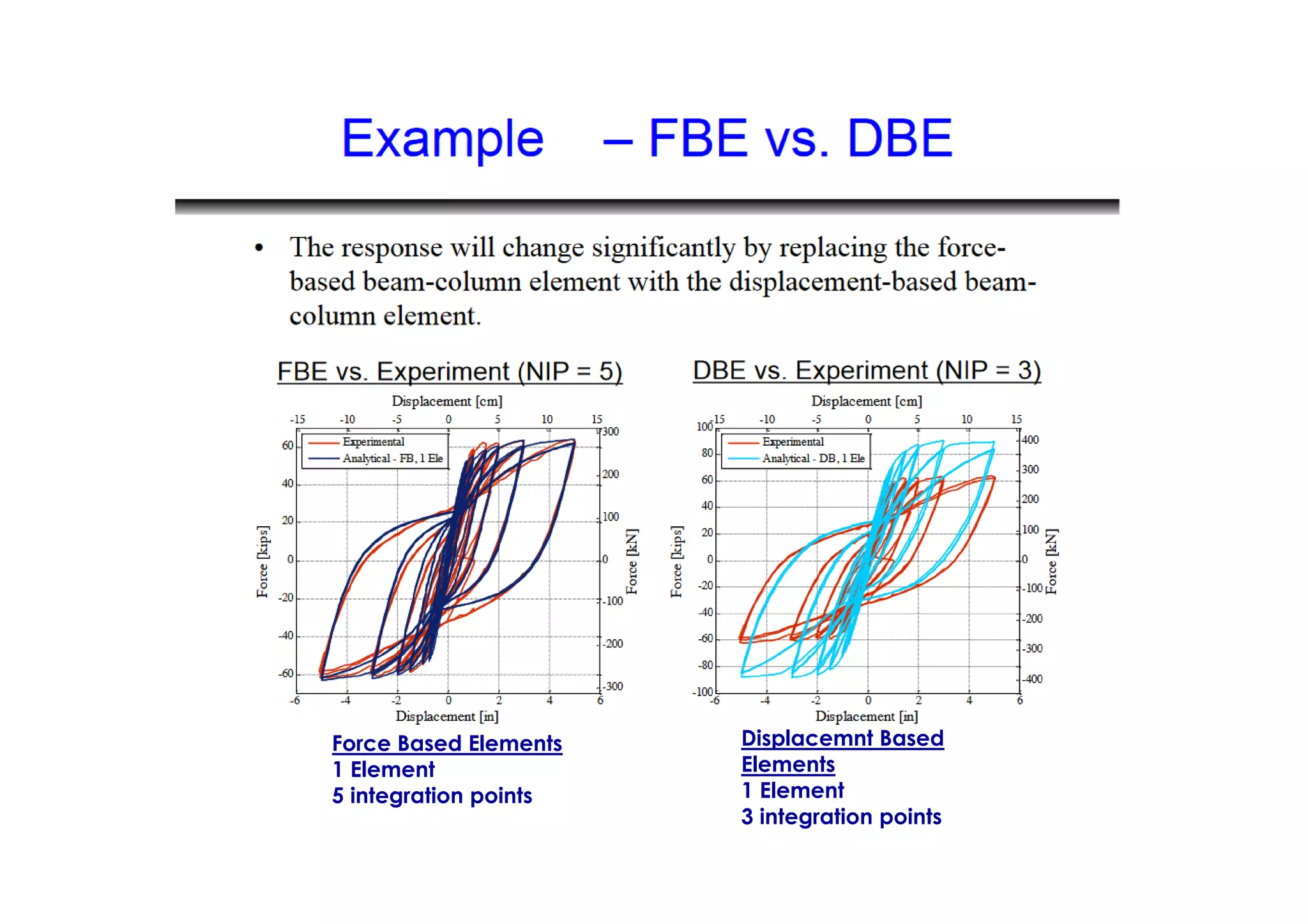

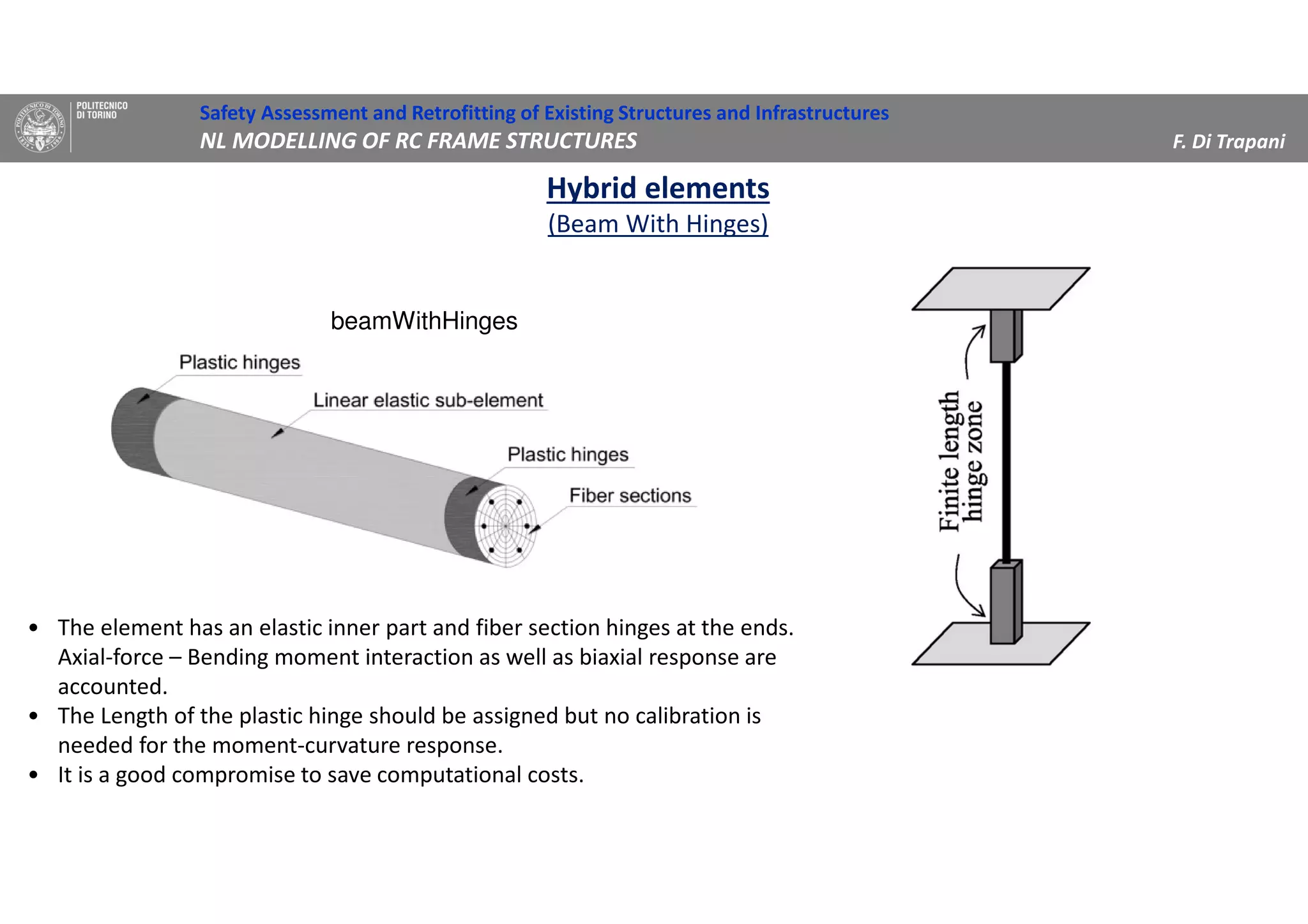

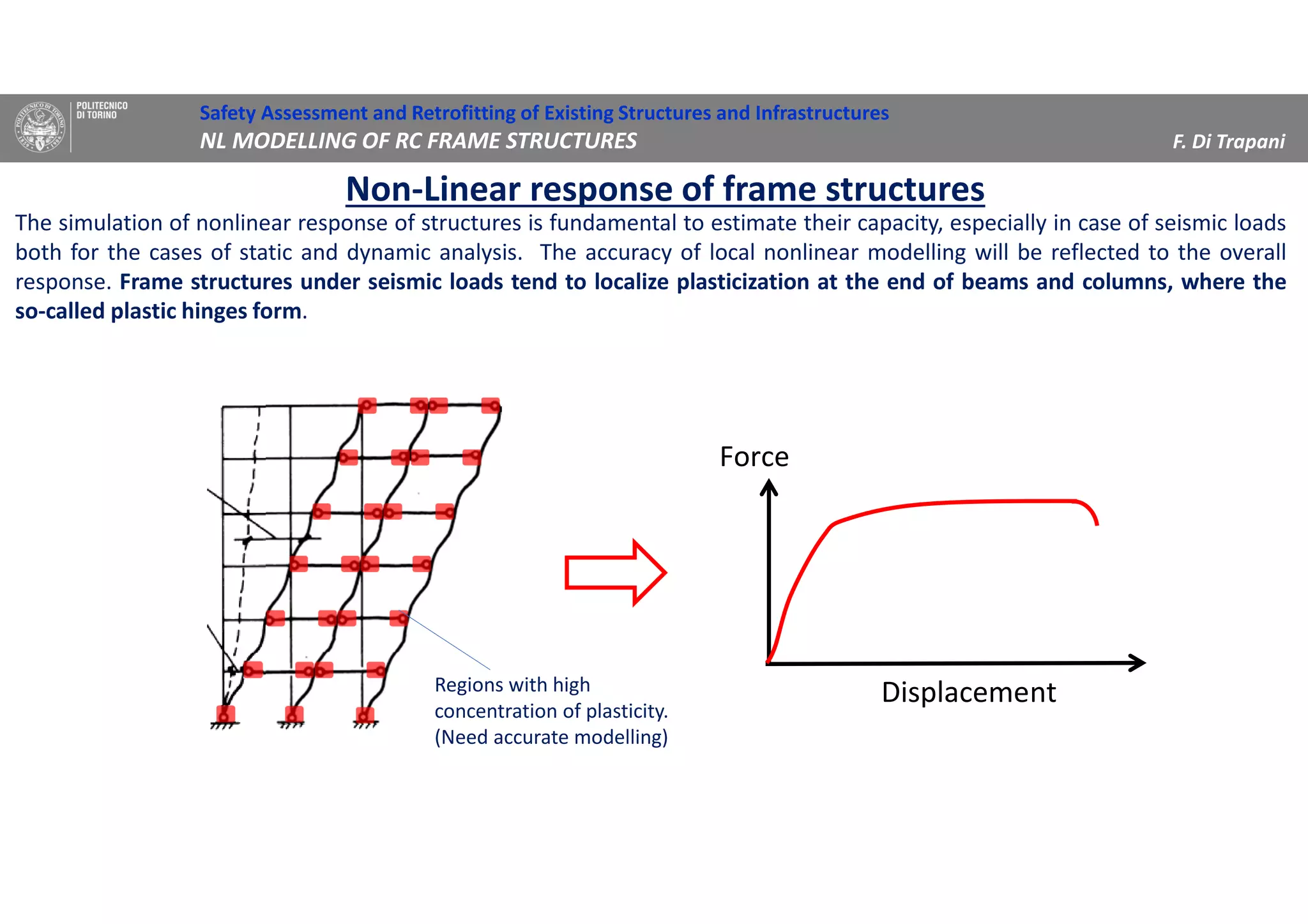

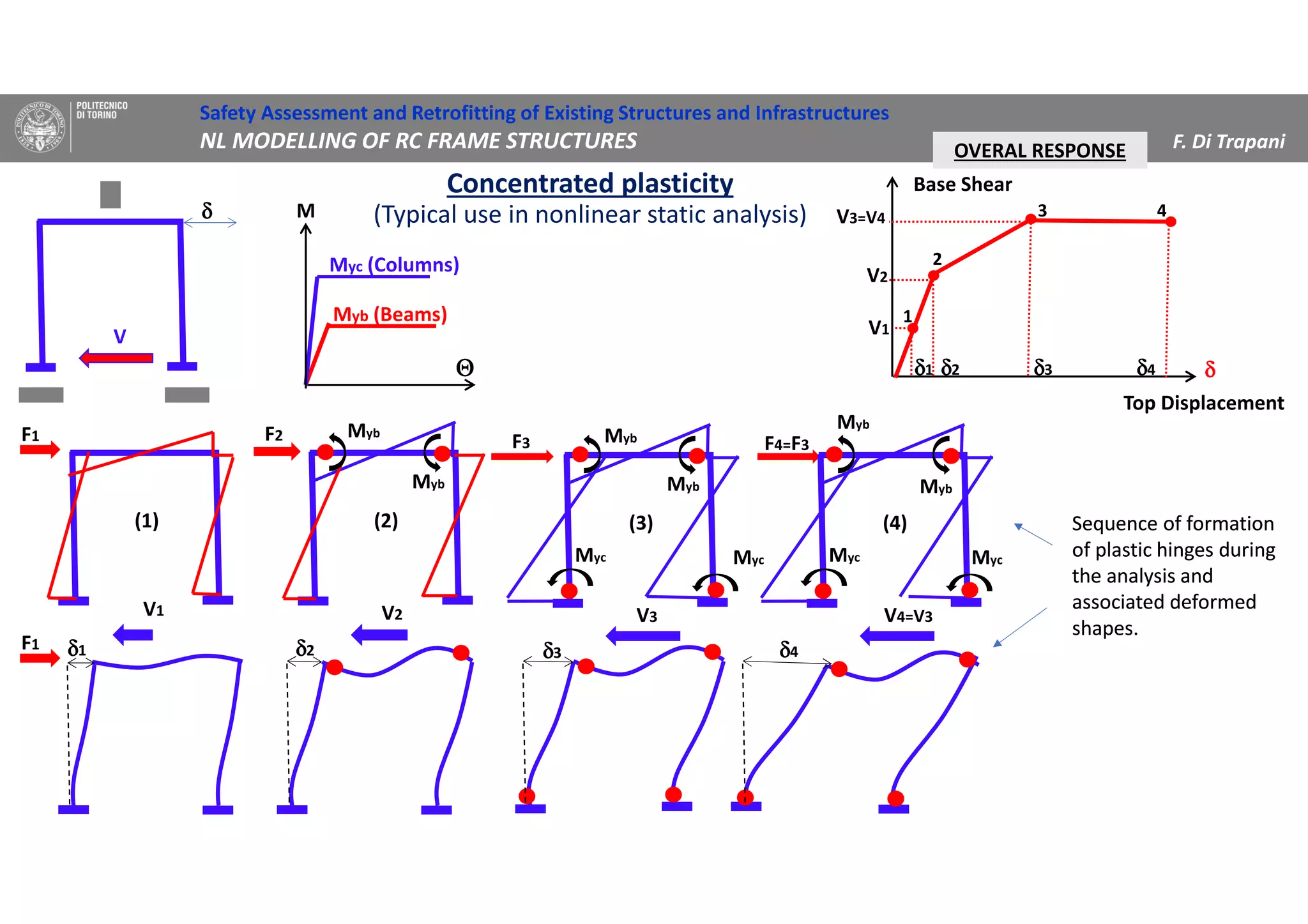

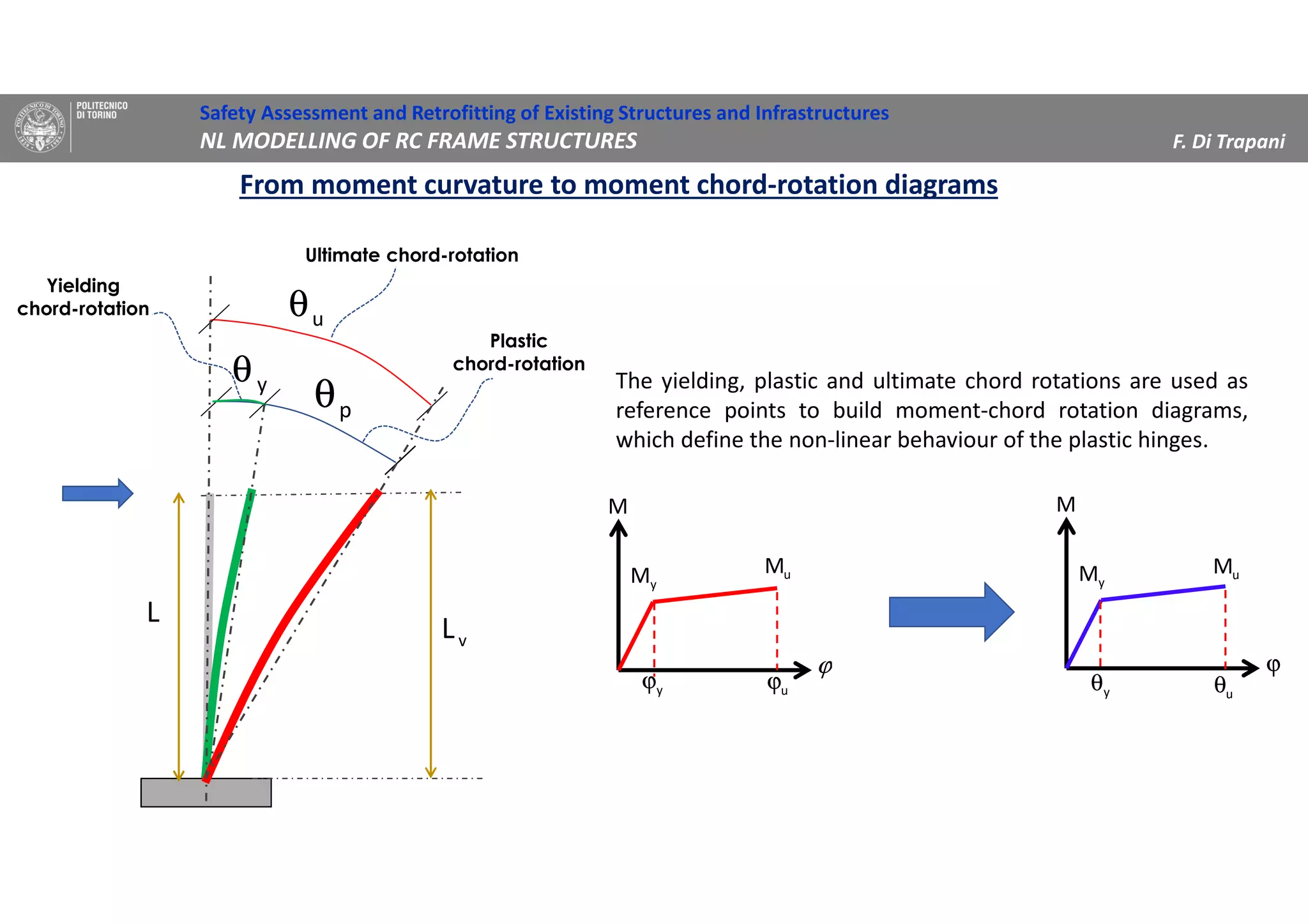

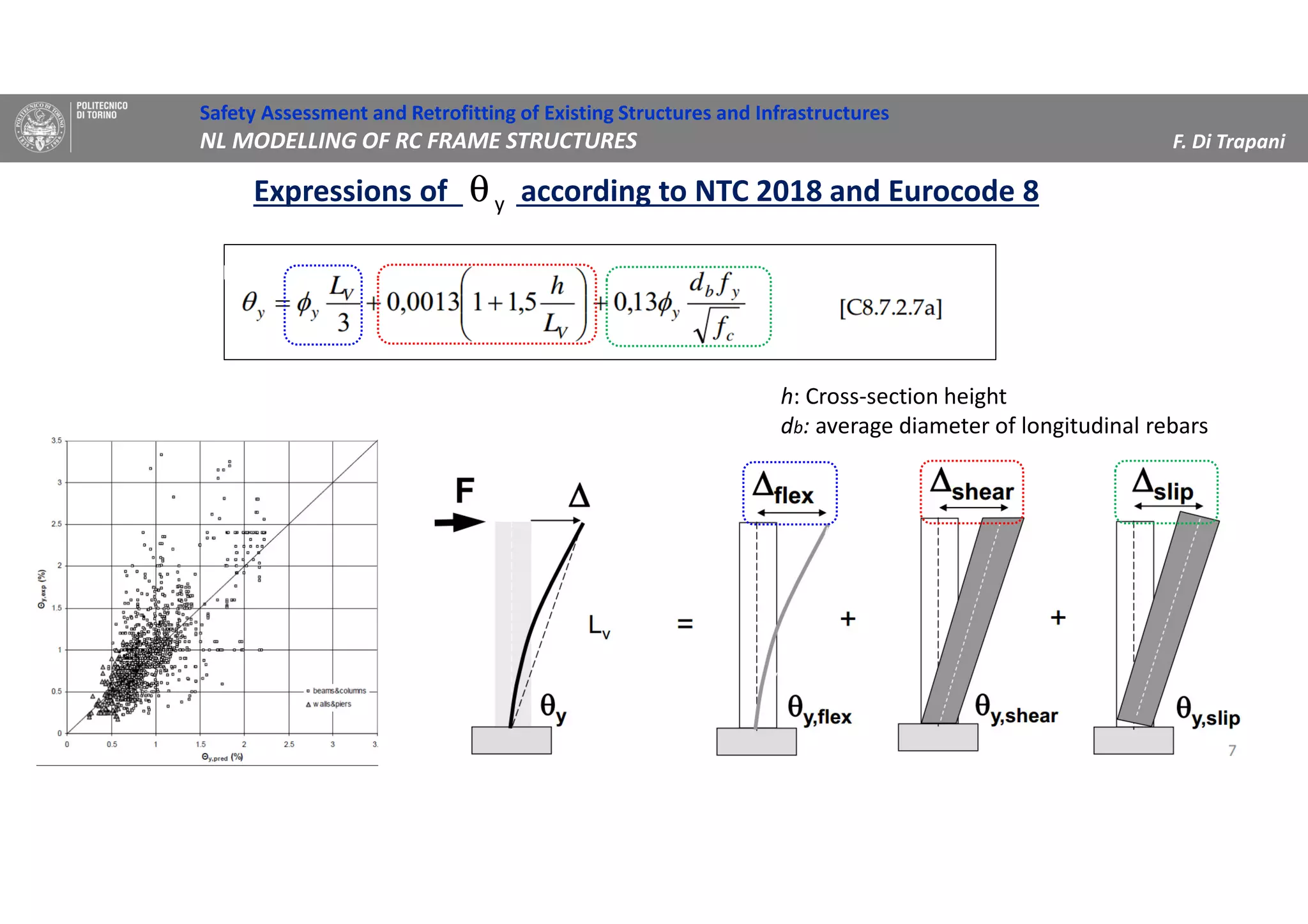

![0

50

100

150

200

250

0 0,0001 0,0002 0,0003 0,0004 0,0005 0,0006

M[kNm]

φφφφ [1/mm]

M-φφφφ diagrams

Column 1

Column 2

Beam

Column 1 Column 2 Beam

N=400 kN N=800 kN N=1200 kN

φφφφu 0.0002059 0.0004 0.000524

φφφφy 0.00000697 0.00001578 0.0000075

My (idealized) 215 97 75

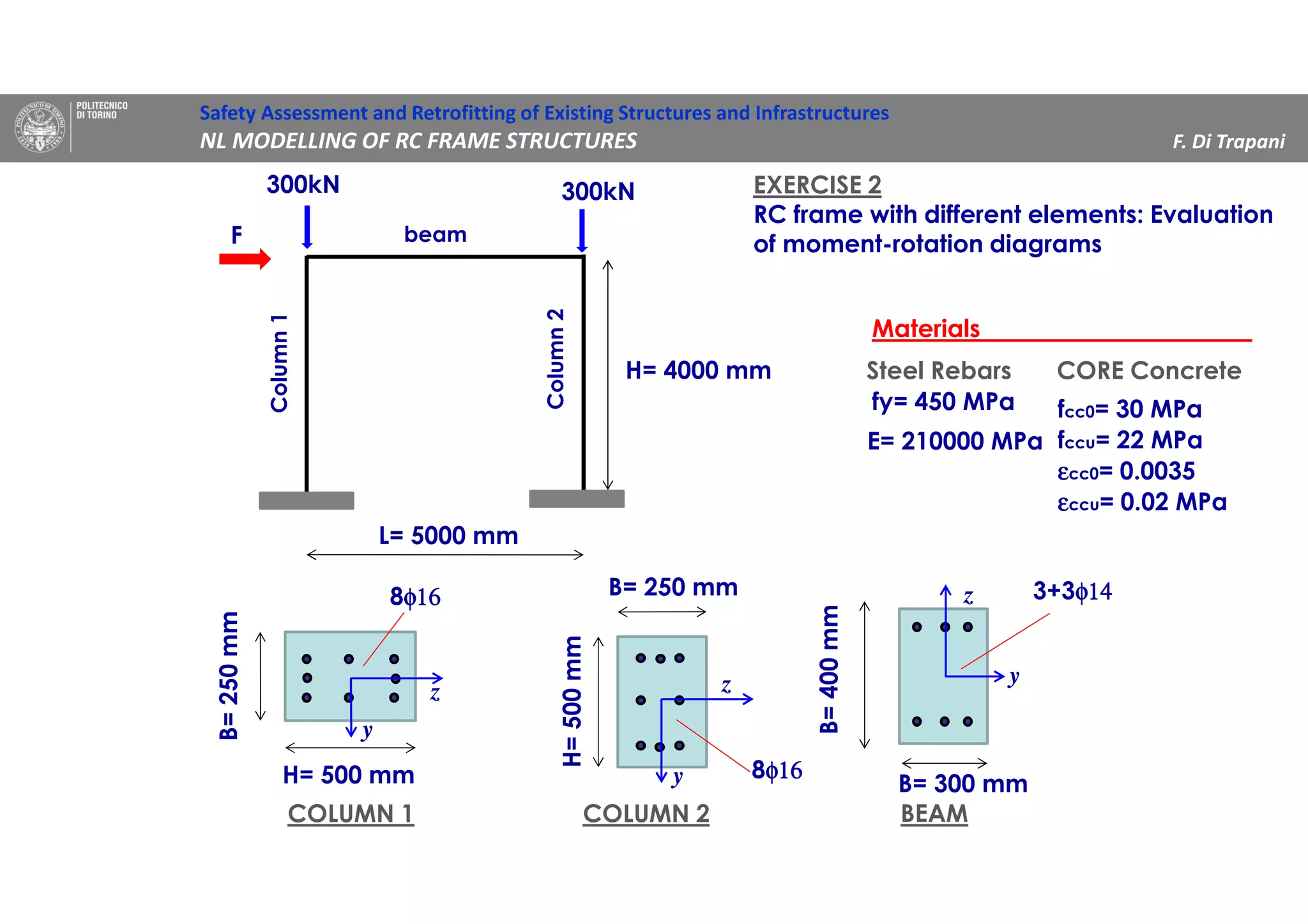

EXERCISE 2

Moment – curvature analysis of the cross-sections

Safety Assessment and Retrofitting of Existing Structures and Infrastructures

NL MODELLING OF RC FRAME STRUCTURES F. Di Trapani

N=300 kN N=300 kN N=0](https://image.slidesharecdn.com/5-200824114726/75/Nonlinear-modelling-of-RC-frame-structures-20-2048.jpg)

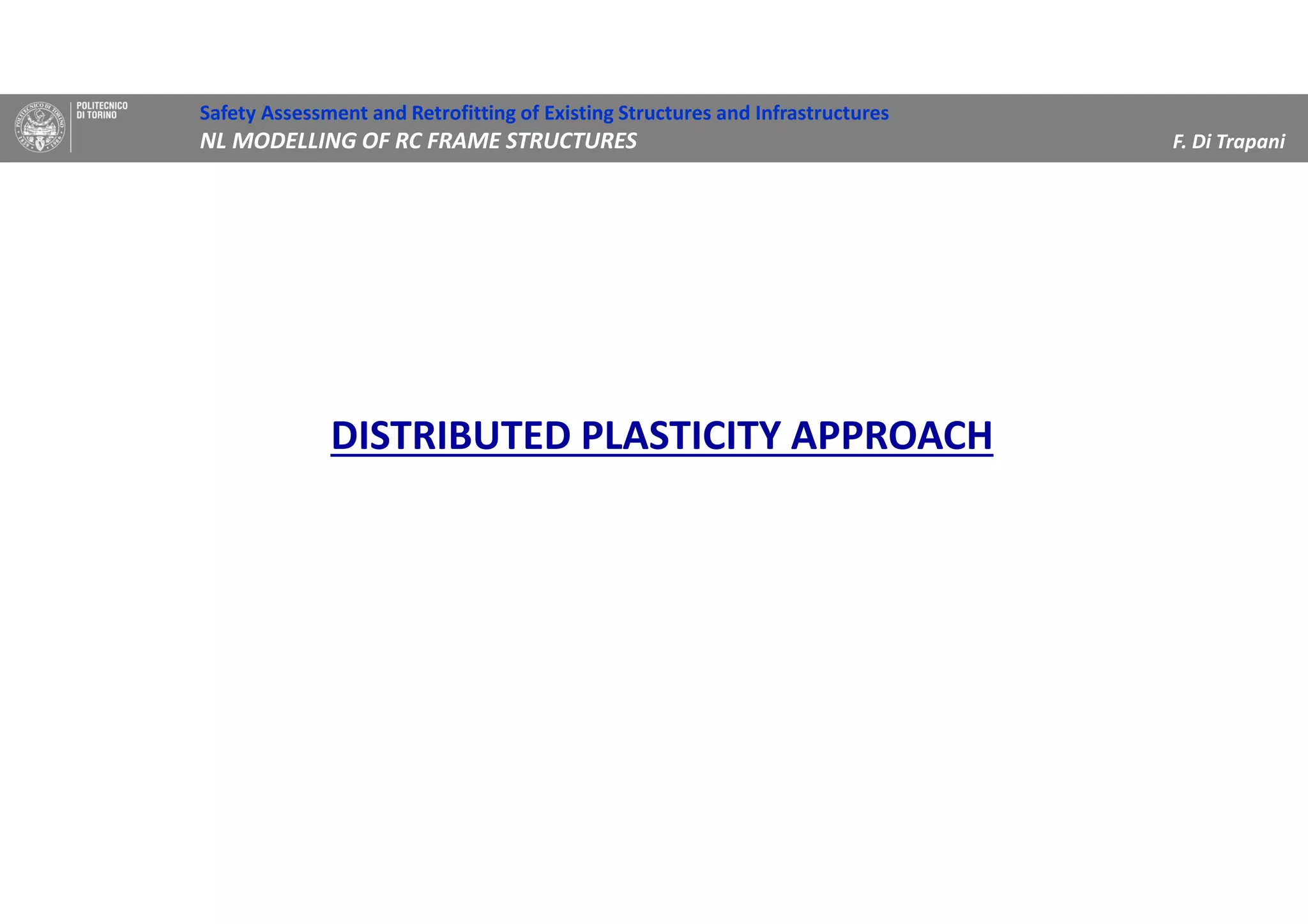

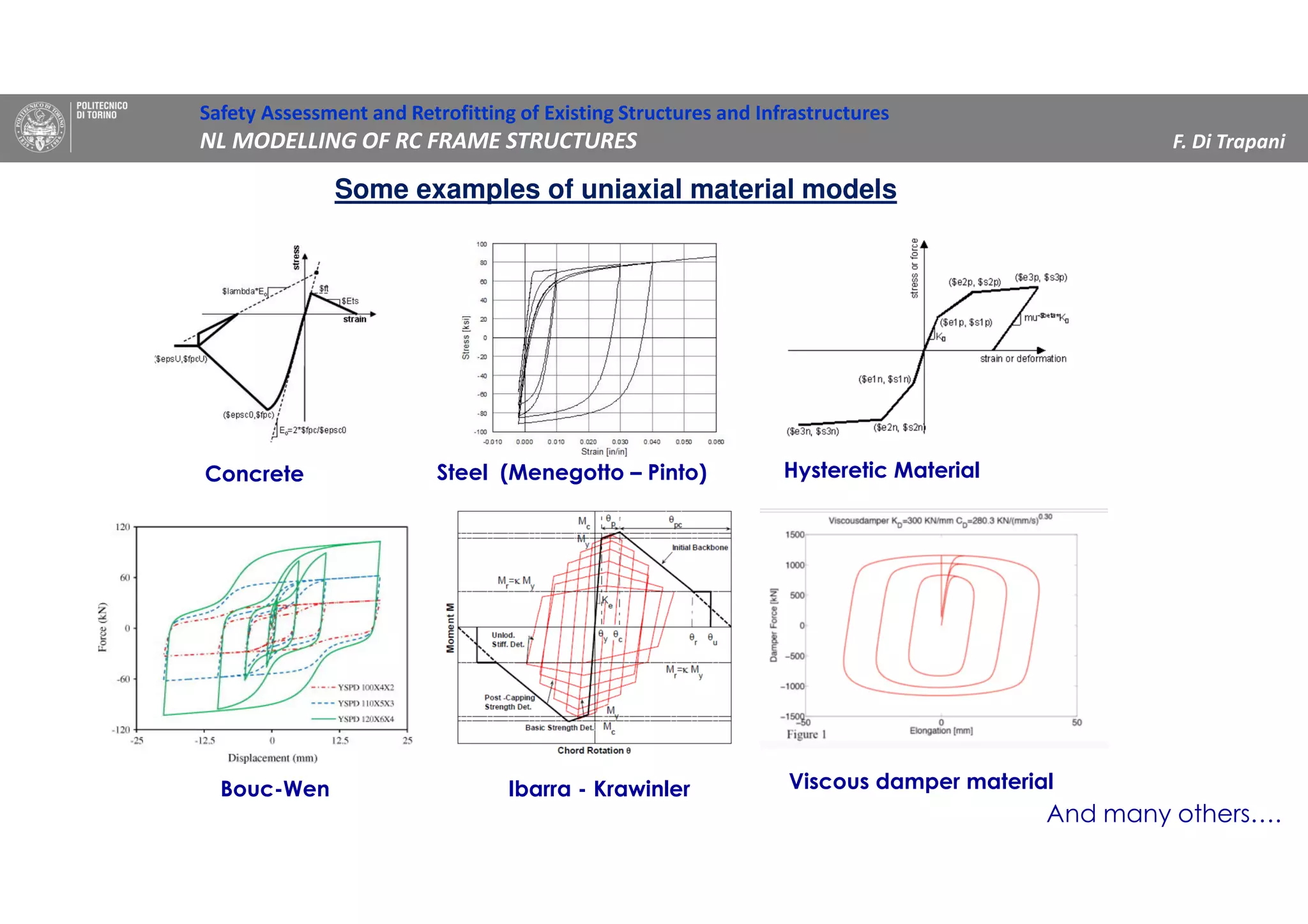

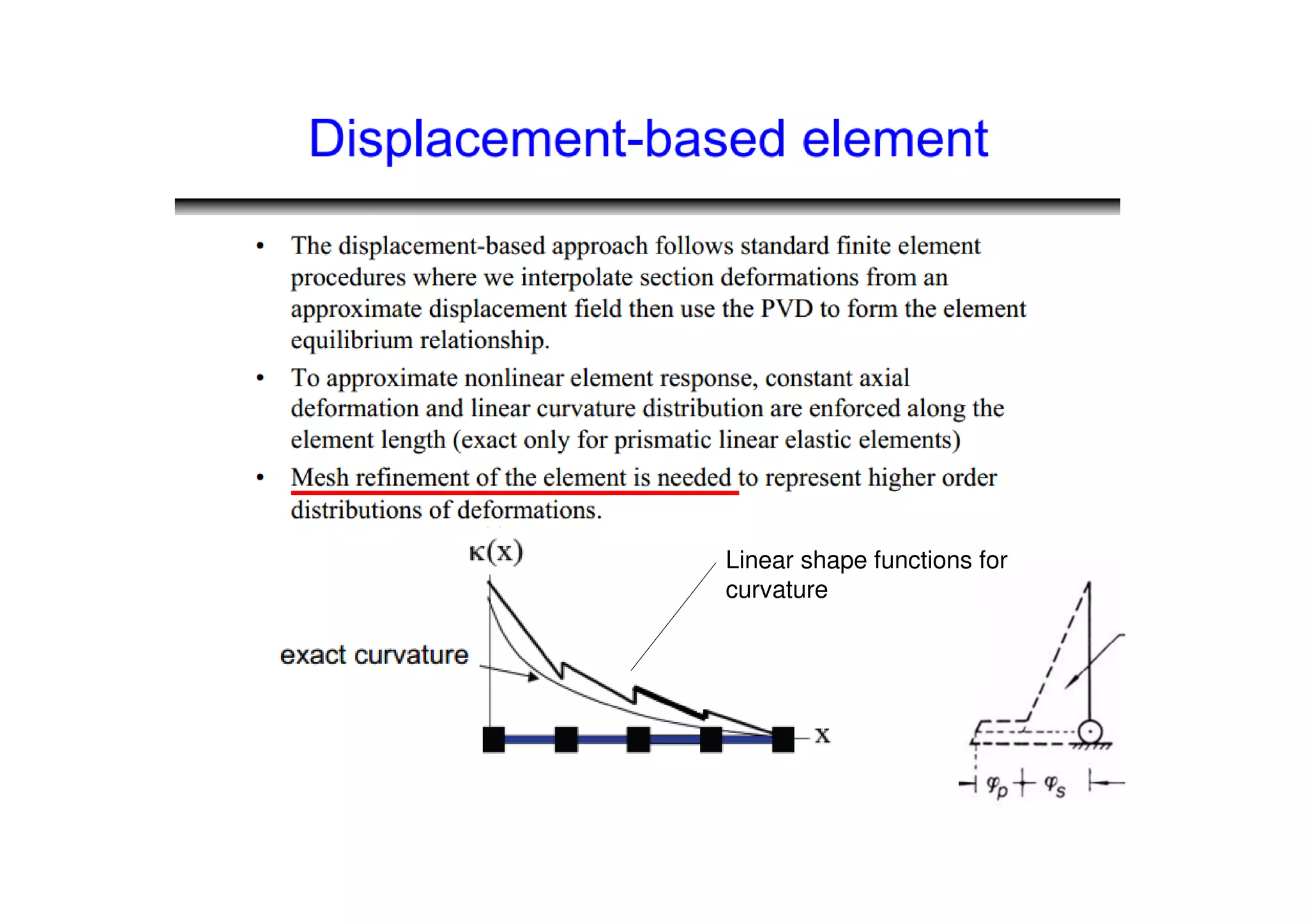

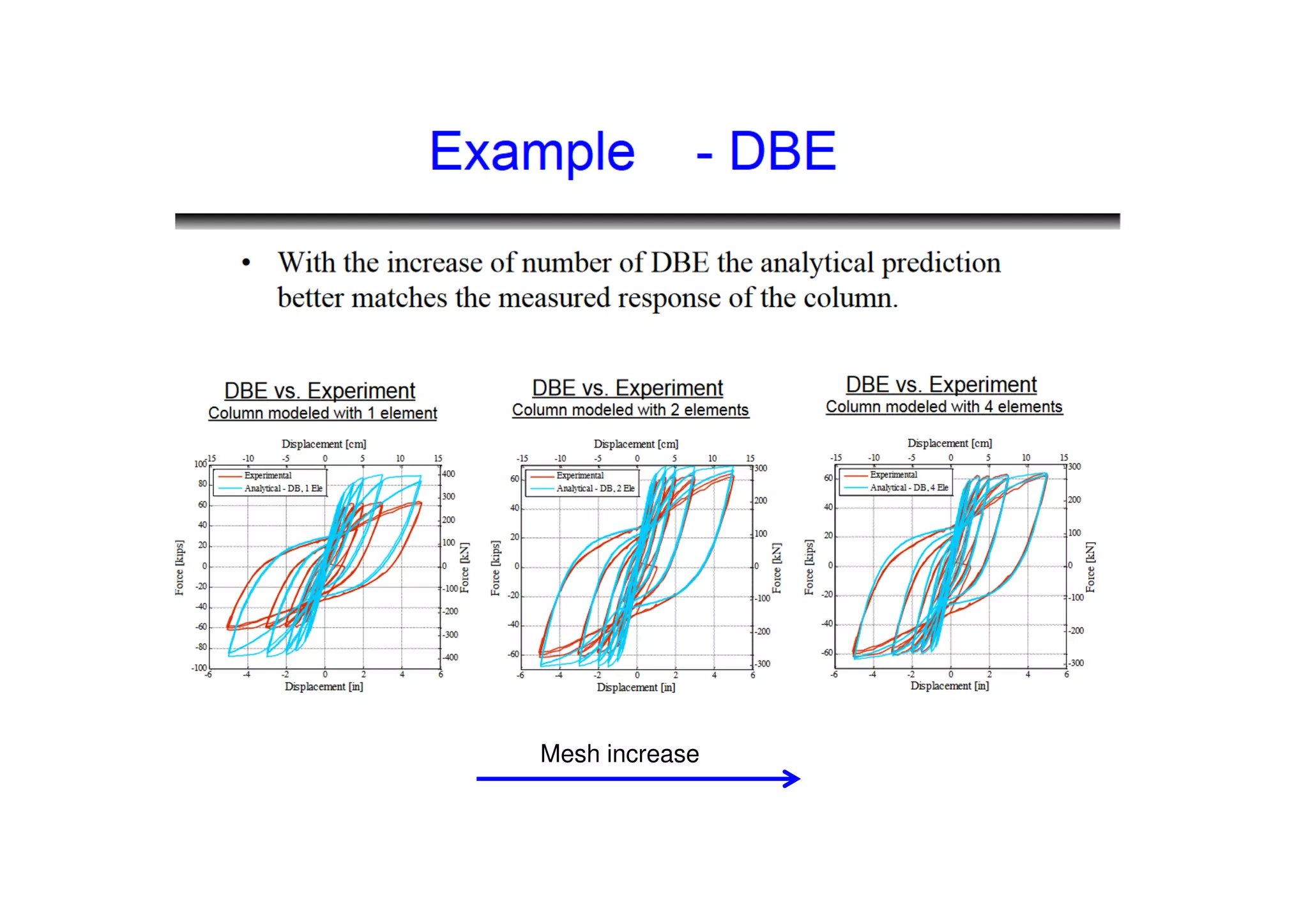

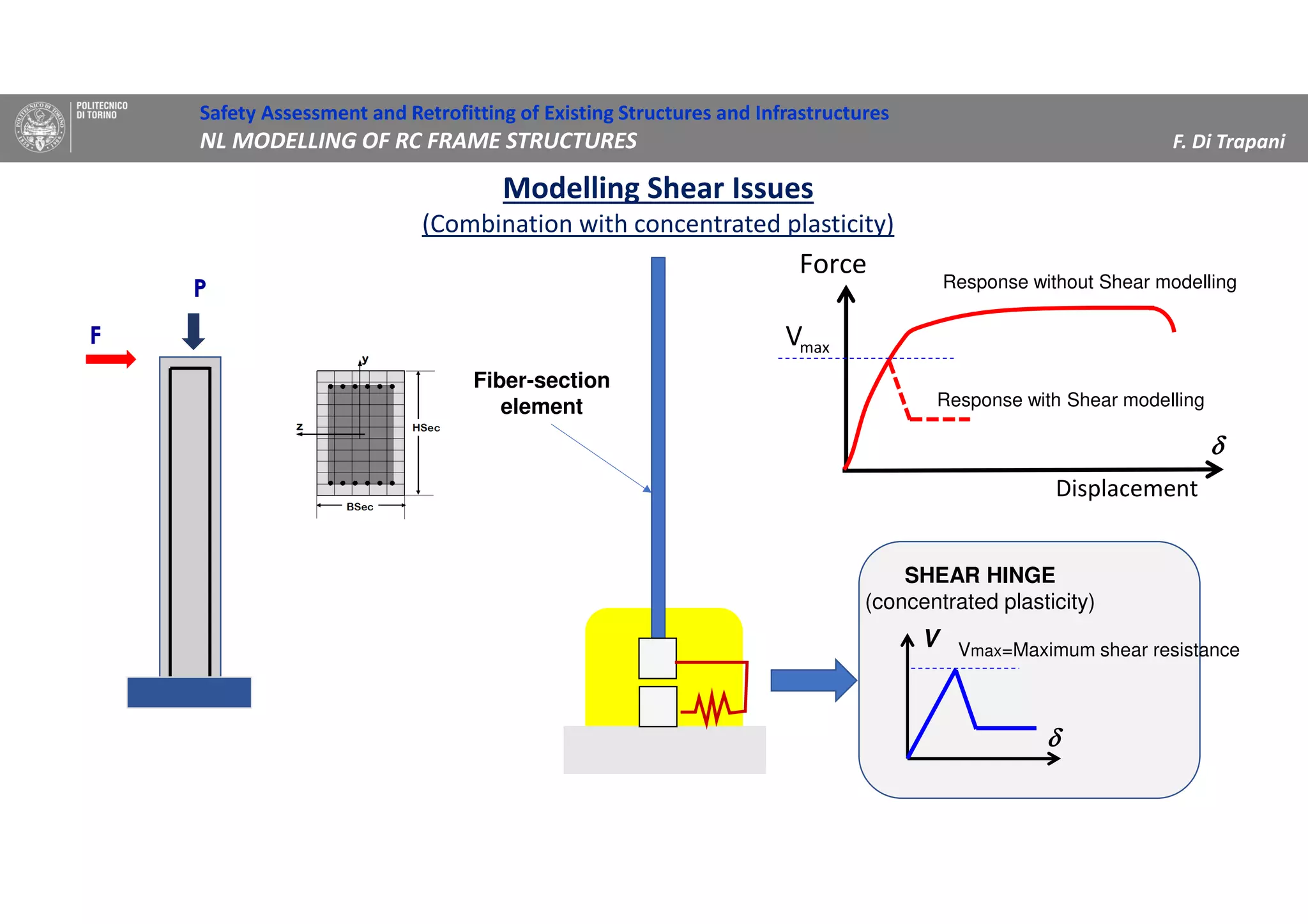

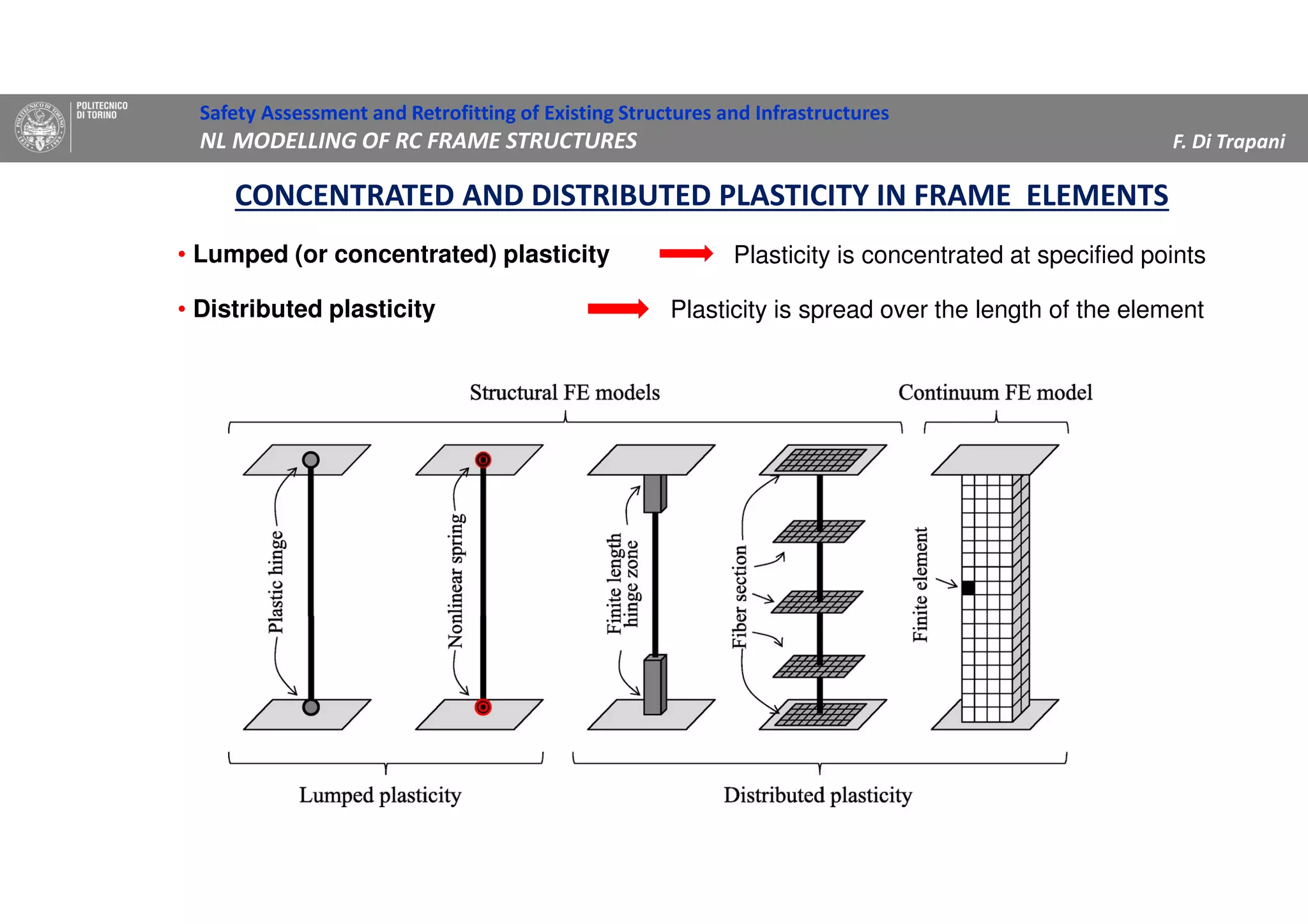

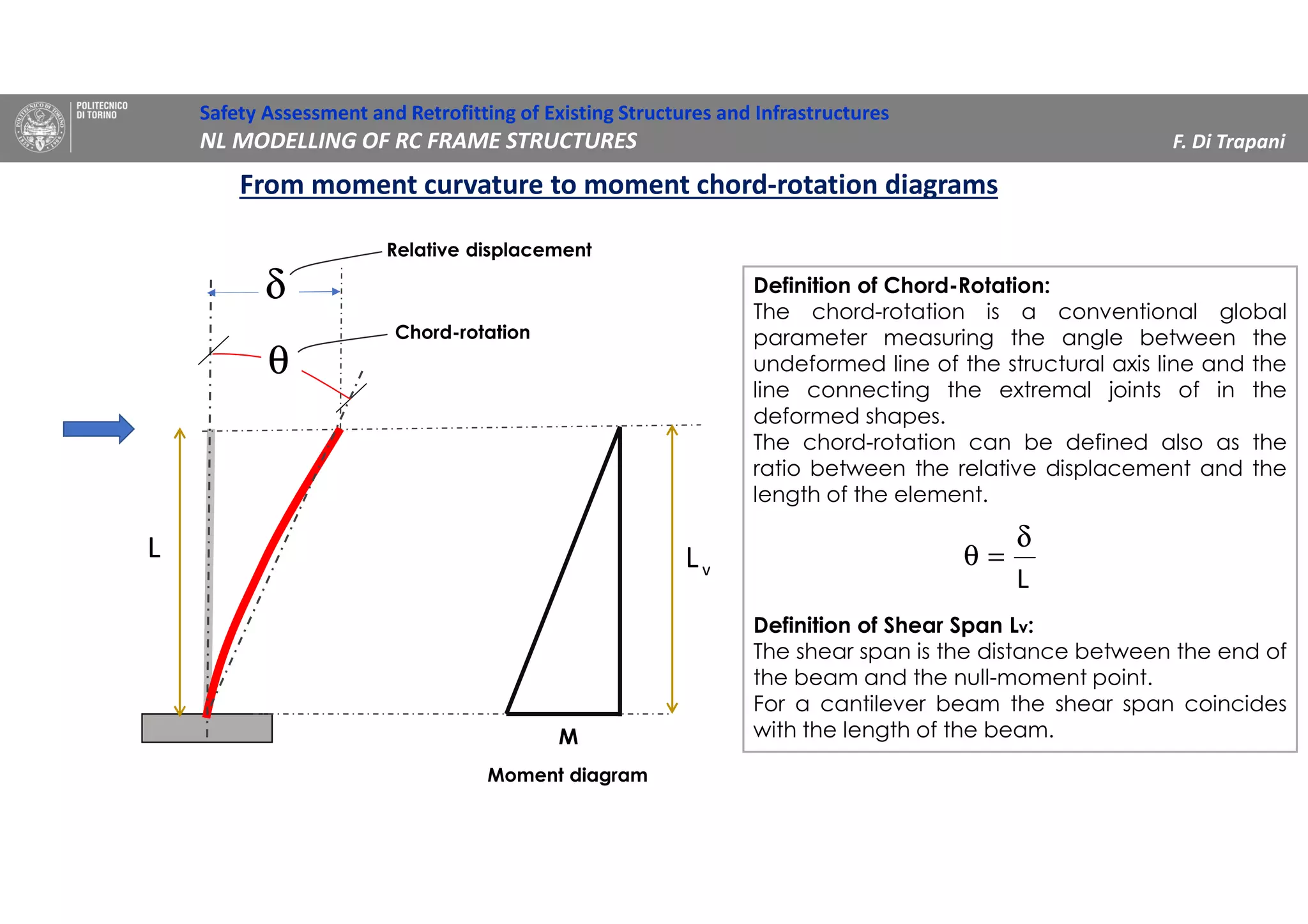

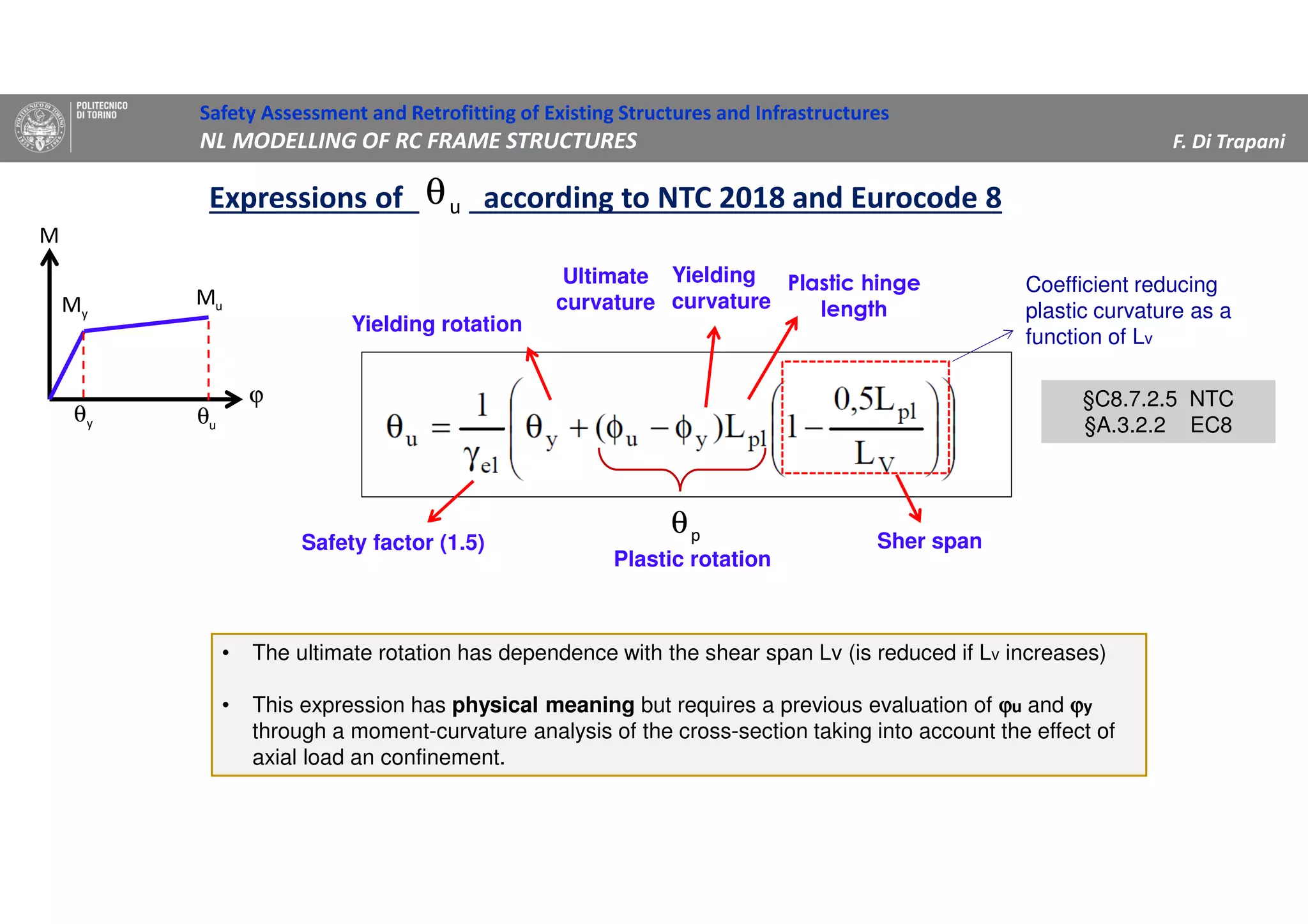

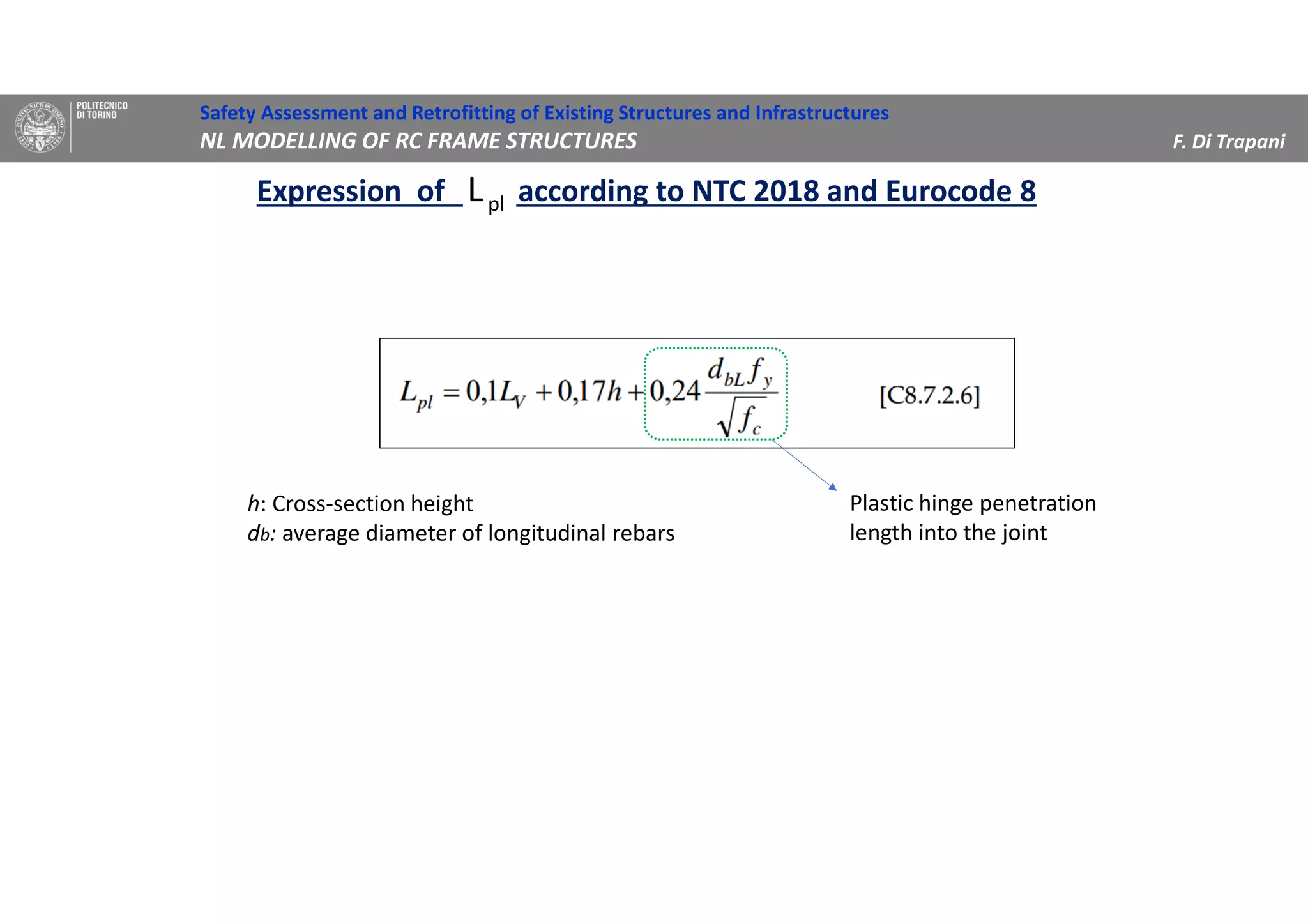

![0

50

100

150

200

250

0 0,05 0,1 0,15 0,2 0,25 0,3 0,35

M[kNm]

ΘΘΘΘ [rad]

M-ΘΘΘΘ diagrams

Column 1

Column 2

Beam

Nu N v (-) φφφφu φφφφy H B L Lv fc dbl N fi long fy Lpl ΘΘΘΘu ΘΘΘΘy My

kN kN (1/mm) (1/mm) (mm) (mm) (mm) (mm) (MPa) (mm) - (MPa) (mm) (mm) (mm) (kNm)

Column 1 3125 300 0.10 0.00021 0.00001 500 250 4000 2000 25 16 8 450 630.6 0.1134 0.0077 215

Column 2 3125 300 0.10 0.00040 0.00002 250 500 4000 2000 25 16 8 450 588.1 0.2078 0.015 97

Beam 3000 0 0.00 0.00052 0.00001 400 300 5000 2500 25 14 6 450 620.4 0.2898 0.0091 75

EXERCISE 2

Evaluation of Moment – Rotation diagrams

Safety Assessment and Retrofitting of Existing Structures and Infrastructures

NL MODELLING OF RC FRAME STRUCTURES F. Di Trapani](https://image.slidesharecdn.com/5-200824114726/75/Nonlinear-modelling-of-RC-frame-structures-21-2048.jpg)