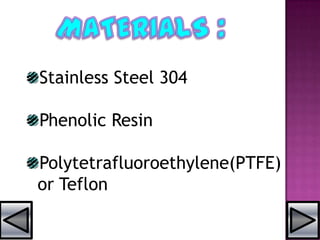

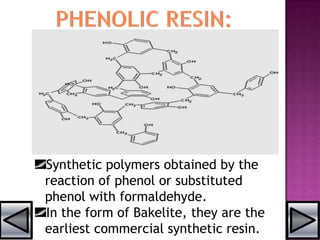

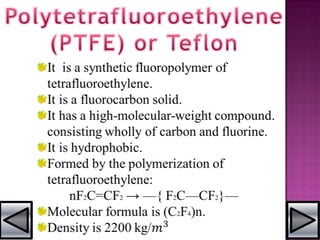

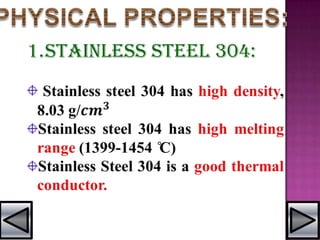

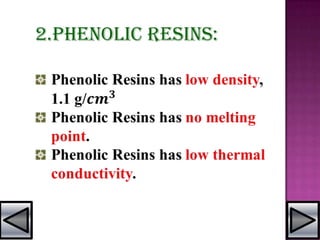

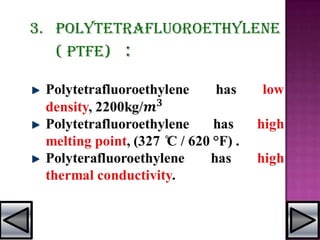

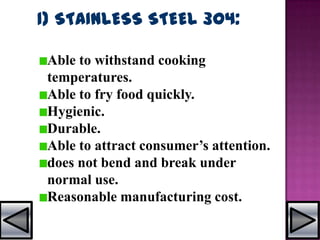

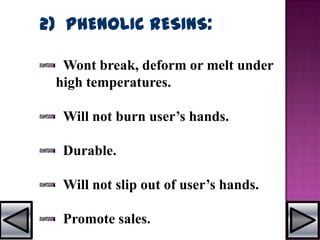

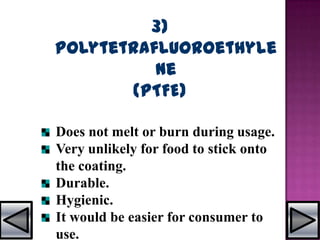

1) Stainless steel 304, phenolic resins, and polytetrafluoroethylene (PTFE) are the main materials used to produce non-stick frying pans.

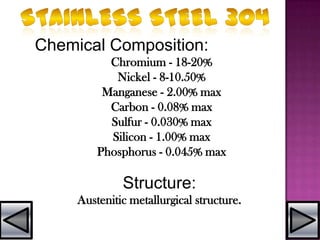

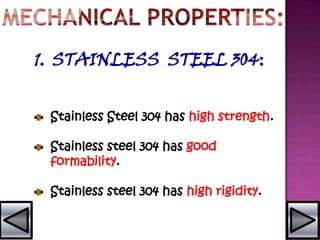

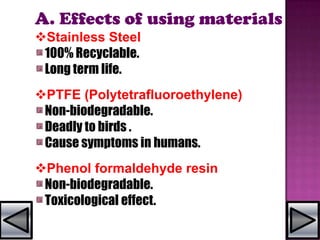

2) Stainless steel 304 provides strength, formability, and rigidity but has poor machinability. PTFE and phenolic resins are strong and durable but PTFE is non-biodegradable and phenolic resins are toxic.

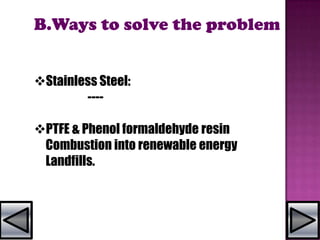

3) While these materials allow pans to withstand high temperatures without sticking to food, they also pose environmental issues like being non-biodegradable or toxic. Alternative more sustainable materials could potentially replace them.