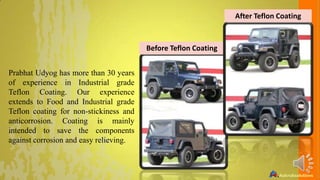

The document outlines six basic types of Teflon coatings, including PTFE, FEP, PFA, ETFE, Teflon®-S one coat, and Teflon®-S dry lubricant coatings, each featuring unique properties like high operating temperatures and excellent chemical resistance. Prabhat Udyog specializes in industrial-grade Teflon coatings with over 30 years of experience, aiming to provide non-stick and anti-corrosion solutions. The coatings are available in various forms, including water-based liquids and powders.