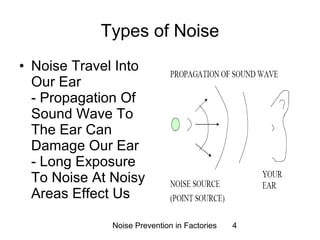

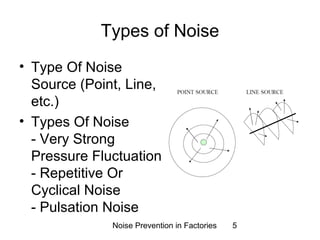

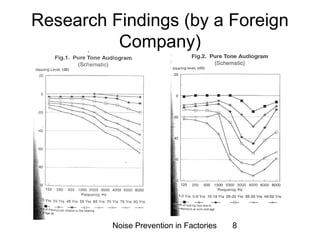

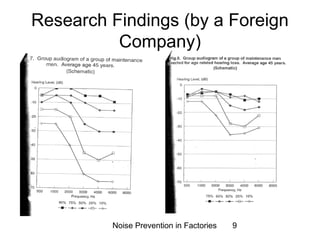

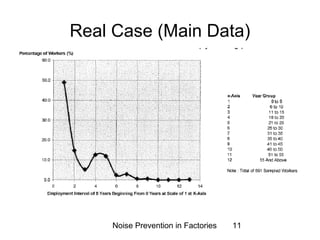

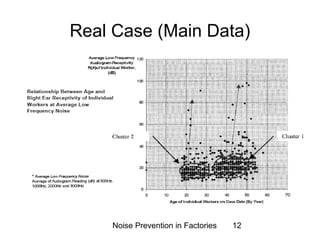

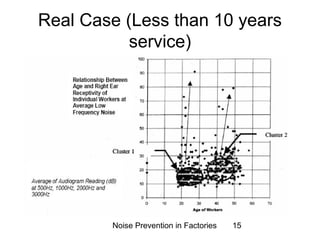

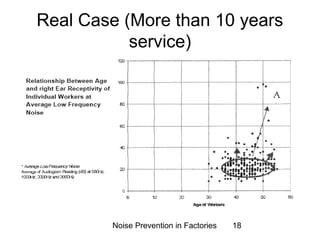

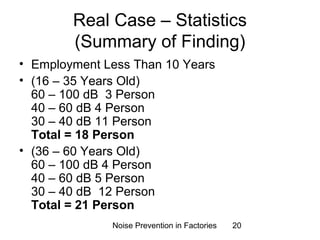

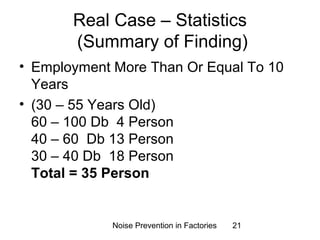

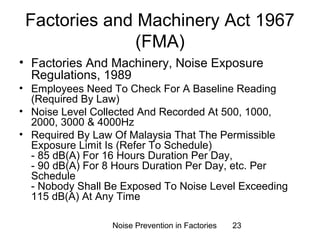

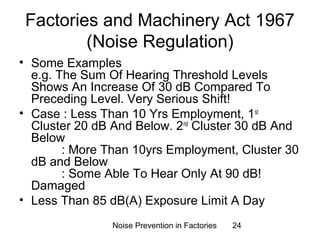

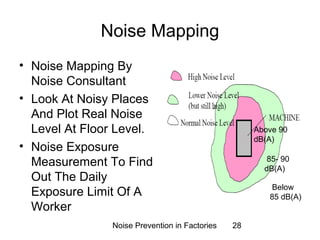

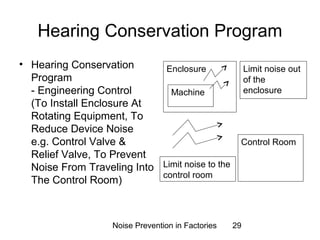

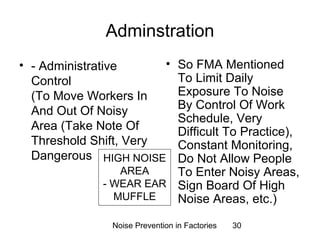

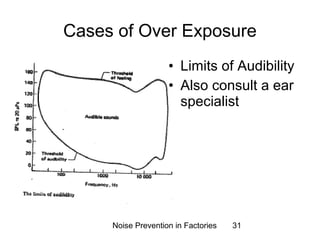

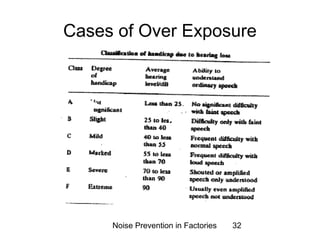

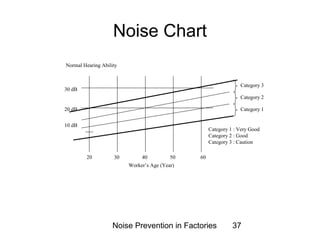

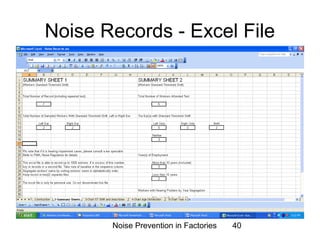

The document discusses noise prevention in factories. It covers types of noise, noise measurement, research findings on noise and hearing loss, a case study analyzing audiometric test results of factory workers, Malaysian laws on noise exposure limits, noise mapping, and engineering and administrative controls for noise prevention. Recommendations include reducing noise at the source, enclosing noisy machinery, limiting worker exposure through schedules and protective gear, and monitoring worker hearing through regular audiometric tests.