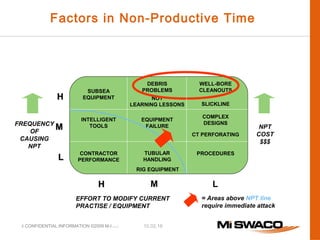

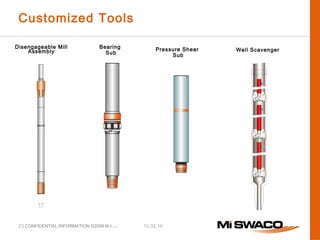

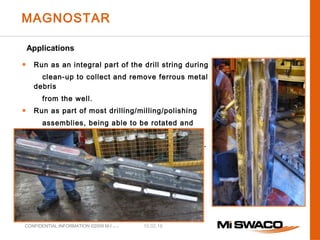

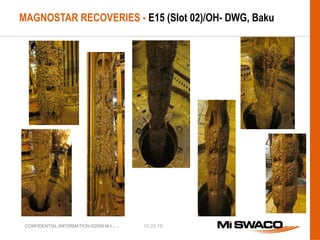

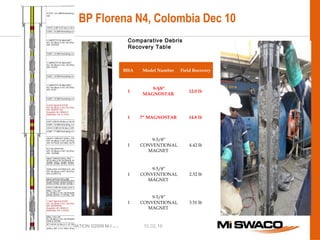

The document discusses tools and methods for cleaning wells and removing debris to improve well completion and productivity. It notes that 30% of non-productive time can be caused by debris or improper planning. Various tools are presented that can help remove debris from blowout preventers, casing, wells and drill strings to reduce costs and risks from debris. These include jetting subs, well protectors, magnets and brushes to capture debris from different parts of the well completion process.