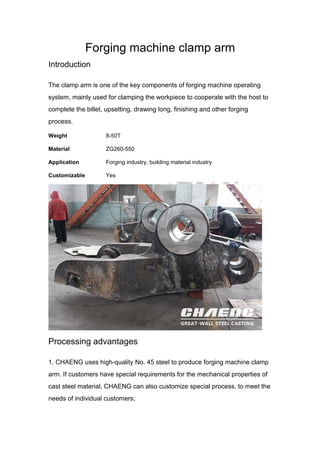

The document discusses the clamp arm, a crucial component of forging machines used for clamping workpieces during various forging processes. It highlights the production capabilities of CHAENG, including customization, quality control, and advanced testing methods, which cater to customer needs in the forging and building material industries. Additionally, it emphasizes CHAENG's cost-effectiveness, fast delivery, and customer service commitment.