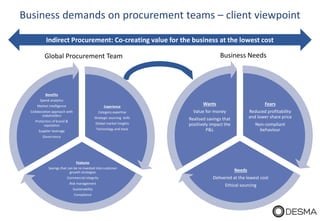

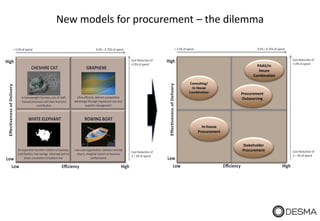

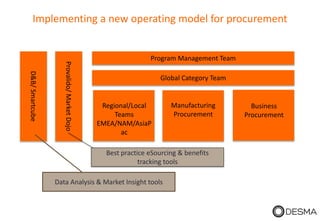

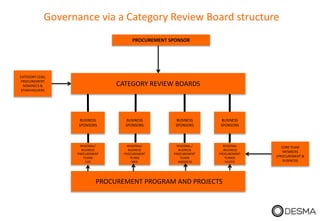

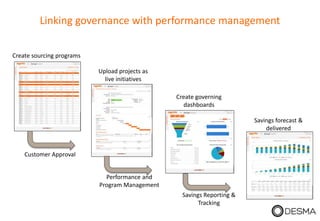

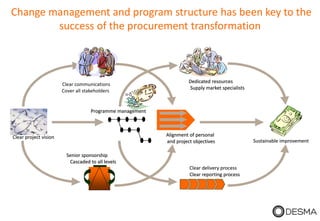

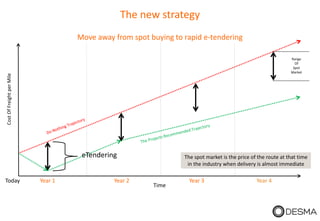

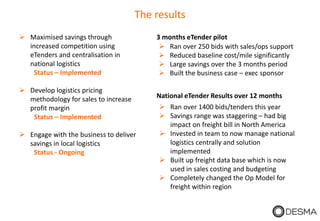

This document provides an overview of a procurement transformation program. It discusses implementing a new procurement operating model, including establishing category review boards for governance. A case study is presented on transforming freight procurement in the US, which centralized freight spending, implemented e-tendering to increase competition, and standardized pricing methodology, resulting in significant cost savings. Key learnings from the program emphasized the importance of executive sponsorship, stakeholder involvement, clear governance structures, and using strategic sourcing best practices.