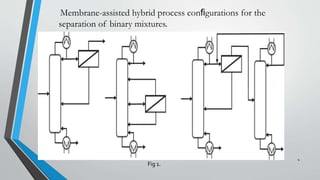

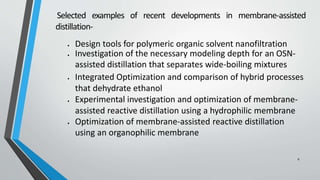

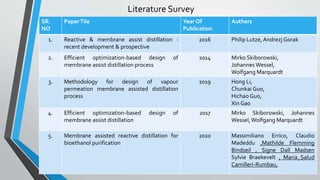

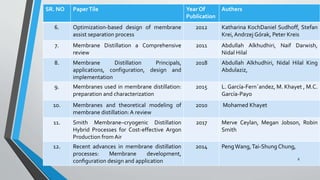

This document summarizes a student project on modeling and simulating a membrane assisted distillation process. It includes an introduction to distillation and membrane assisted distillation processes. The literature review covers recent developments in membrane assisted distillation, including different membrane configurations and characteristics. The document also outlines the steps to implement a new unit operation in the DWSIM simulation software and references several papers on membrane assisted distillation processes.

![Membrane Configuration

Direct Contact Membrane Distillation[DCMD]

Air Gap Membrane Distillation.[AGMD]

Sweeping Gas Membrane Distillation[SGMD]

Vacuum Membrane Distillation[VMD]

10](https://image.slidesharecdn.com/newmicrosoftpowerpointpresentation-220330171845/85/New-Microsoft-PowerPoint-Presentation-pptx-10-320.jpg)