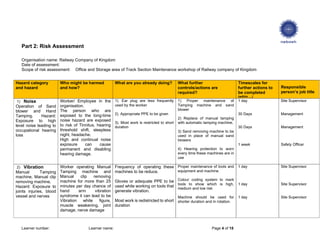

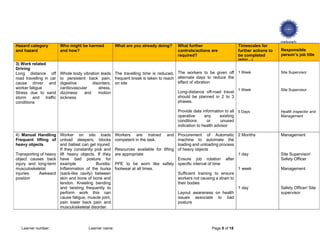

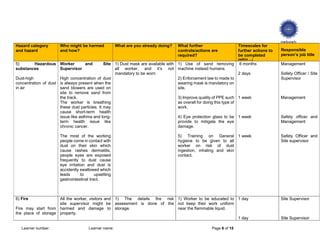

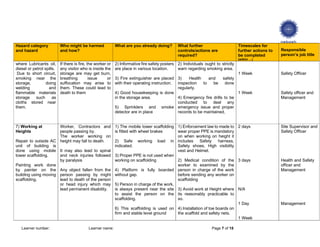

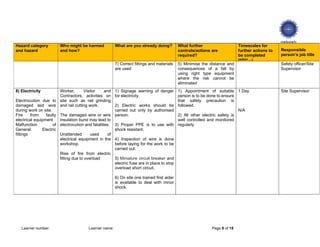

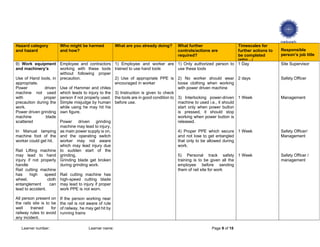

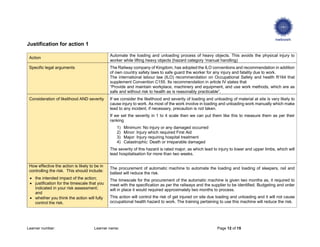

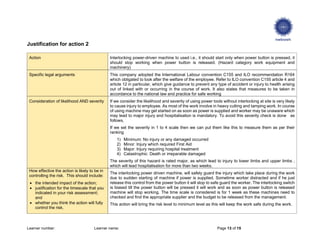

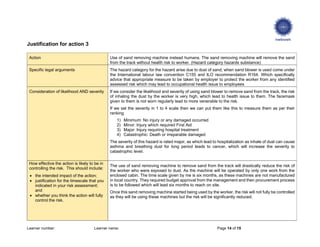

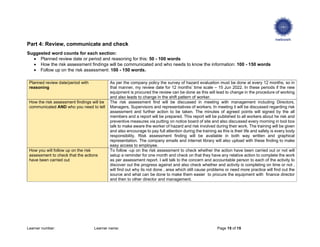

The document is a risk assessment declaration for the Railway Company of Kingdom, outlining the company's operations and the risks associated with its maintenance workshops and storage areas. It details specific hazards, potential impacts on workers, and existing control measures, while recommending further actions to mitigate risks such as noise, vibration, fire, and manual handling. The assessment emphasizes the importance of compliance with safety standards and the need for ongoing monitoring and training.