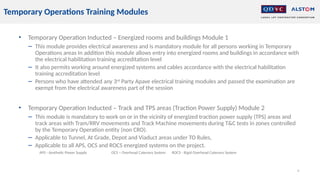

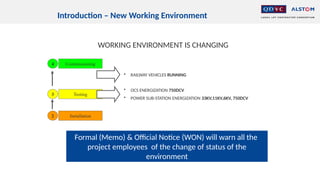

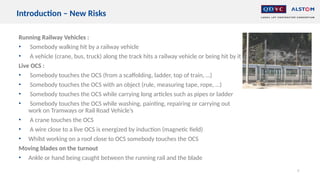

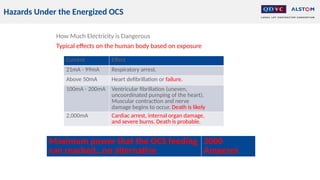

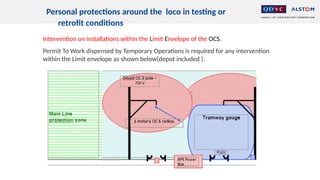

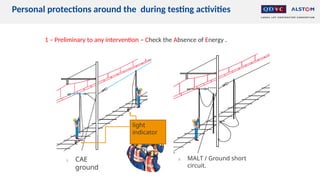

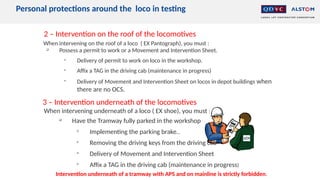

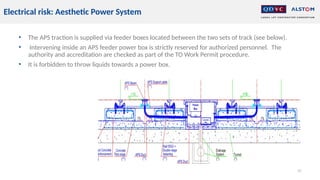

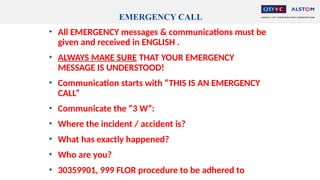

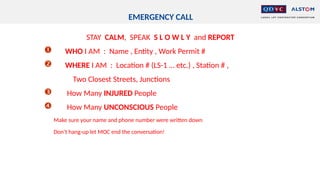

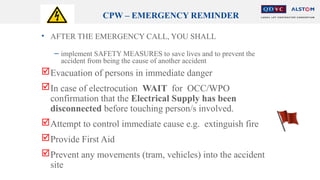

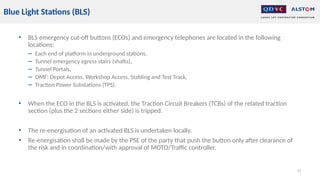

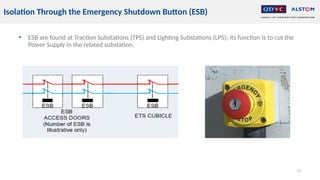

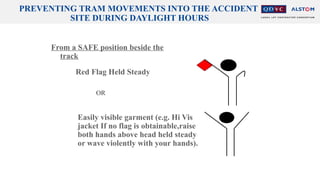

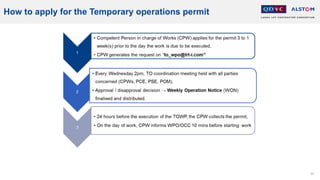

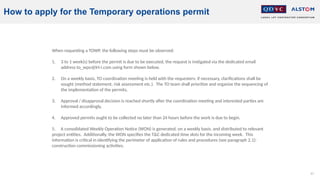

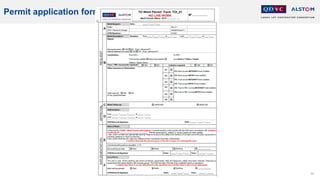

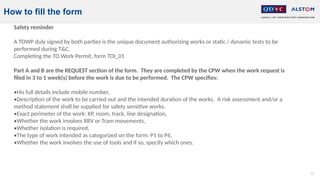

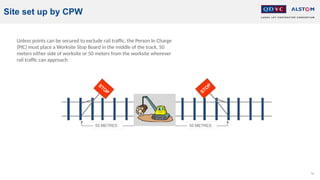

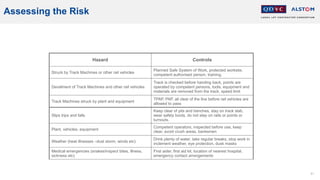

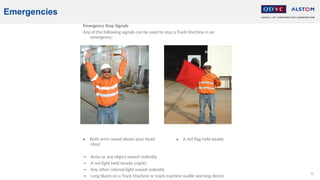

The document outlines mandatory training modules for personnel working in energized environments, emphasizing safety protocols during operations around trams and traction power supply areas. Key training includes understanding the hazards of working near electrical systems and the importance of obtaining work permits and isolation certificates before proceeding with any electrical work. It also details safety measures, emergency procedures, and responsibilities of workers to ensure compliance and protection against electrical hazards.